Ferromagnetic foam microcrystalline glass and preparation method thereof

A foam glass-ceramic and ferrimagnetic technology, applied in the field of foam glass production, can solve the problems of cumbersome steps, high energy consumption, and complex composition, and achieve the effects of easy availability of raw materials, reduction of carbon emissions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

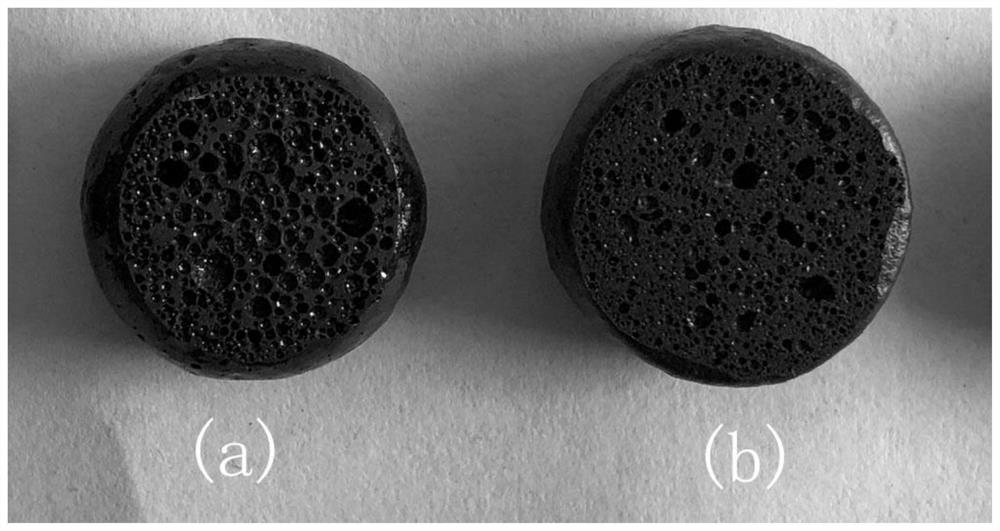

Image

Examples

Embodiment 1

[0074] A ferrimagnetic foamed glass-ceramic contains 85% waste glass powder and 15% ferrimagnetic crystal forming agent. Based on the preparation of 10kg, the waste glass powder and the ferrimagnetic crystal forming agent are in the following mass ratio:

[0075] Waste glass powder 8.5kg

[0076] Ferrimagnetic crystal former 1.5kg.

[0077] The content of carbon powder (C) in the ferrimagnetic crystal forming agent is 3%, ferric oxide (Fe 2 o 3 ) content is 97%. Based on the preparation of 10kg, the ferrimagnetic crystal forming agent is in the following mass percentages:

[0078] Toner (C) 0.3kg

[0079] Ferric oxide (Fe 2 o 3 ) 9.7kg.

[0080] The preparation steps are as follows:

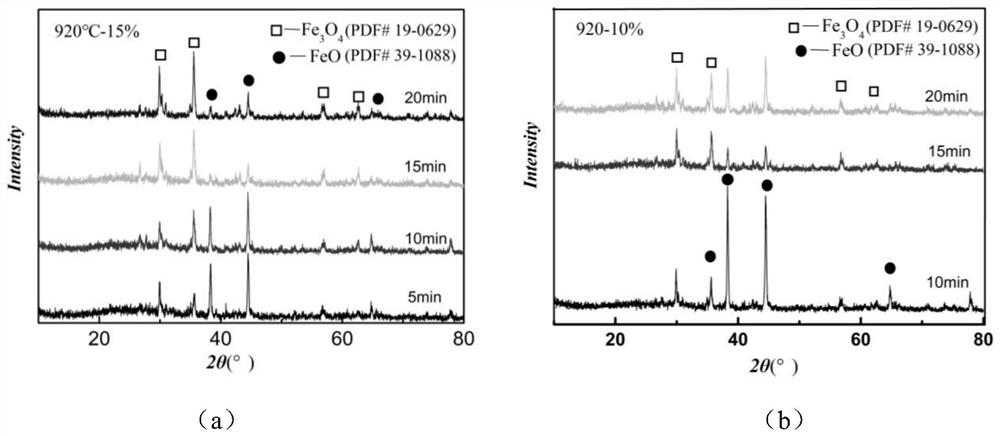

[0081] The recovered waste glass is crushed and ground to a powder of less than 80 meshes, and the carbon powder and ferric oxide are uniformly mixed according to the mass ratio to prepare a ferrimagnetic crystal forming agent. Weigh 8.5kg of waste glass powder and 1.5kg of ferromagneti...

Embodiment 2

[0087] A ferrimagnetic foamed glass-ceramic contains 90% waste glass powder and 10% ferrimagnetic crystal forming agent. Based on the preparation of 10kg, the waste glass powder and the ferrimagnetic crystal forming agent are in the following mass ratio:

[0088] Waste glass powder 9.0kg

[0089] Ferrimagnetic crystal former 1.0kg

[0090] The content of carbon powder (C) in the ferrimagnetic crystal forming agent is 3%, ferric oxide (Fe 2 o 3 ) content is 97%. Based on the preparation of 10kg, the ferrimagnetic crystal forming agent is in the following mass percentages:

[0091] Toner (C) 0.3kg

[0092] Ferric oxide (Fe 2 o 3 ) 9.7kg.

[0093] The preparation steps are as follows:

[0094] The recovered waste glass is crushed and ground to a powder of less than 80 meshes, and the carbon powder and ferric oxide are uniformly mixed according to the mass ratio to prepare a ferrimagnetic crystal forming agent. Weigh 9.0kg of waste glass powder and 1.0kg of ferromagnetic c...

Embodiment 3

[0099] A ferrimagnetic foam glass-ceramic, the content of waste glass powder is 95%, and the content of ferrimagnetic crystal forming agent is 5%. Based on the preparation of 10kg, the waste glass powder and the ferrimagnetic crystal forming agent are in the following mass ratio:

[0100] Waste glass powder 9.5kg

[0101] Ferrimagnetic crystal former 0.5kg

[0102] The content of carbon powder (C) in the ferrimagnetic crystal forming agent is 3%, ferric oxide (Fe 2 o 3 ) content is 97%. Based on the preparation of 10kg, the ferrimagnetic crystal forming agent is in the following mass percentages:

[0103] Toner (C) 0.3kg

[0104] Ferric oxide (Fe 2 o 3 ) 9.7kg.

[0105] The preparation steps are the same as in Example 1, and the hysteresis loop of the ferrimagnetic foamed glass-ceramics prepared in this example is as follows Figure 4 As shown, the ferrimagnetic crystal former content is 5%. Depend on Figure 4 It can be seen that the specific saturation magnetic mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com