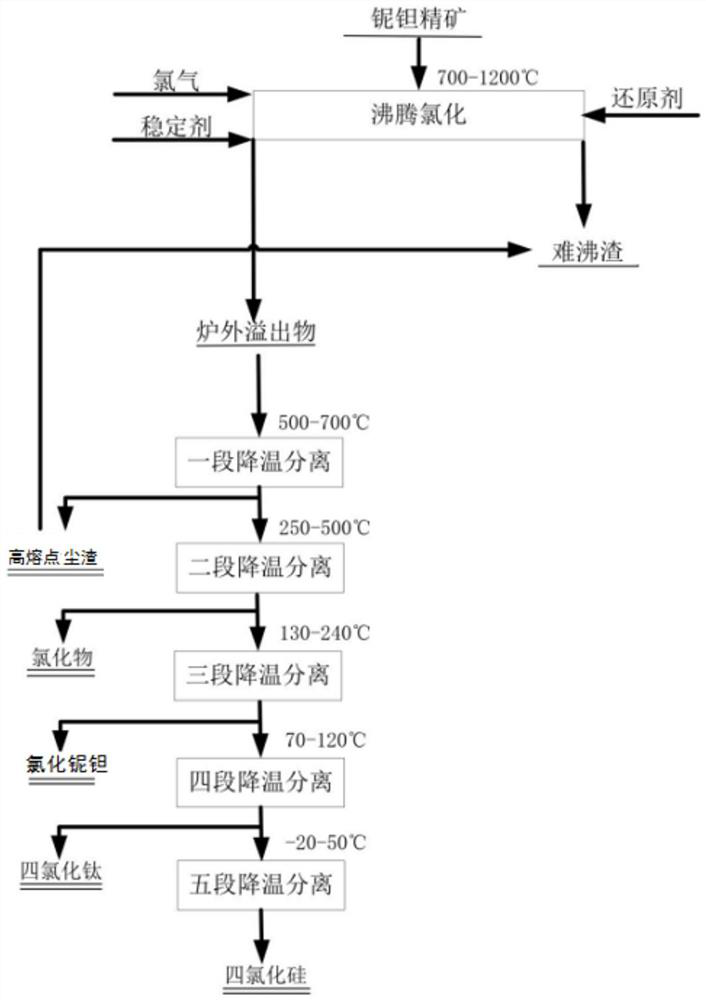

A kind of boiling chlorination extraction method of niobium and tantalum concentrate

A technology of boiling chlorination and extraction method, which is applied in the field of metallurgy, can solve the problems of low added value of products, low attention, high pollution, etc., and achieve the effects of reducing the discharge of three wastes, significant environmental benefits, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The mass fractions of the oxides of the niobium-tantalum concentrate of the present embodiment are respectively: Nb 2 o 5 17.08%, Ta 2 o 5 40.0%, TiO 2 7.45%, SiO 2 10.45%, the boiling chlorination extraction method of the niobium-tantalum concentrate of the present embodiment comprises the following steps:

[0029] Mix niobium and tantalum concentrate with coke and metal silicon, add it to the boiling chlorination furnace and pass chlorine gas to react, the mass ratio of niobium tantalum concentrate, coke, metal silicon and chlorine gas is 1:0.1:0.1:1.5, tantalum niobium The adding speed of concentrate is 1000g / min, the adding speed of coke is 260g / min, the adding speed of metal silicon is 240g / min, the adding speed of chlorine gas is 2800g / min, the reaction temperature is 700-900℃, the reaction product overflows the boiling chlorination furnace The overflow, the overflow is subjected to continuous five-stage cooling and separation, and the refractory slag in t...

Embodiment 2

[0037] The mass fractions of the oxides of the niobium-tantalum concentrate of the present embodiment are respectively: Nb 2 o 5 50.12%, Ta 2 o 5 11.56%, TiO 2 10.87%, SiO 2 8.21%, the boiling chlorination extraction method of the niobium-tantalum concentrate of the present embodiment comprises the following steps:

[0038] Mix niobium and tantalum concentrate with coal powder, petroleum coke and silicon carbide, add it to a fluidized chlorination furnace and feed chlorine gas for reaction, the mass ratio of niobium and tantalum concentrate, coal powder, petroleum coke, silicon carbide and chlorine gas is 1: 0.1:0.2:0.3:3, the addition rate of tantalum and niobium concentrate is 1000g / min, the addition rate of coal powder is 260g / min, the addition rate of petroleum coke is 60g / min, the addition rate of silicon carbide is 390g / min, the addition rate of chlorine gas The reaction temperature is 2800g / min, and the reaction temperature is 900-1180°C. The reaction generates ov...

Embodiment 3

[0046] The mass fractions of the oxides of the niobium-tantalum concentrate of the present embodiment are respectively: Nb 2 o 5 3.45%, Ta 2 o 5 0.58%, TiO 2 28.51%, REO16.12%, SiO 2 10.17%, the boiling chlorination extraction method of the niobium-tantalum concentrate of the present embodiment comprises the following steps:

[0047] Mix niobium and tantalum concentrate with petroleum coke and metal silicon, add chlorine gas into the boiling chlorination furnace for reaction, the mass ratio of niobium and tantalum concentrate, petroleum coke, metal silicon and chlorine gas is 1:0.4:0.4:5, The addition rate of tantalum and niobium concentrate is 1000g / min, the addition rate of petroleum coke is 400g / min, the addition rate of metal silicon is 400g / min, the addition rate of chlorine gas is 4800g / min, the reaction temperature is 900-1200°C, and the reaction produces overflowing boiling chlorine For the spill outside the chlorination furnace, the overflow is subjected to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com