A method for separating, recycling and reusing blended fabrics

A blended fabric, separation and recycling technology, applied in recycling technology, textile decomposition and recovery, textiles and papermaking, etc., can solve the problems of difficult to achieve recycling of blended products, difficult to achieve industrialization, poor separation effect, etc. Low, high recovery efficiency, small performance loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

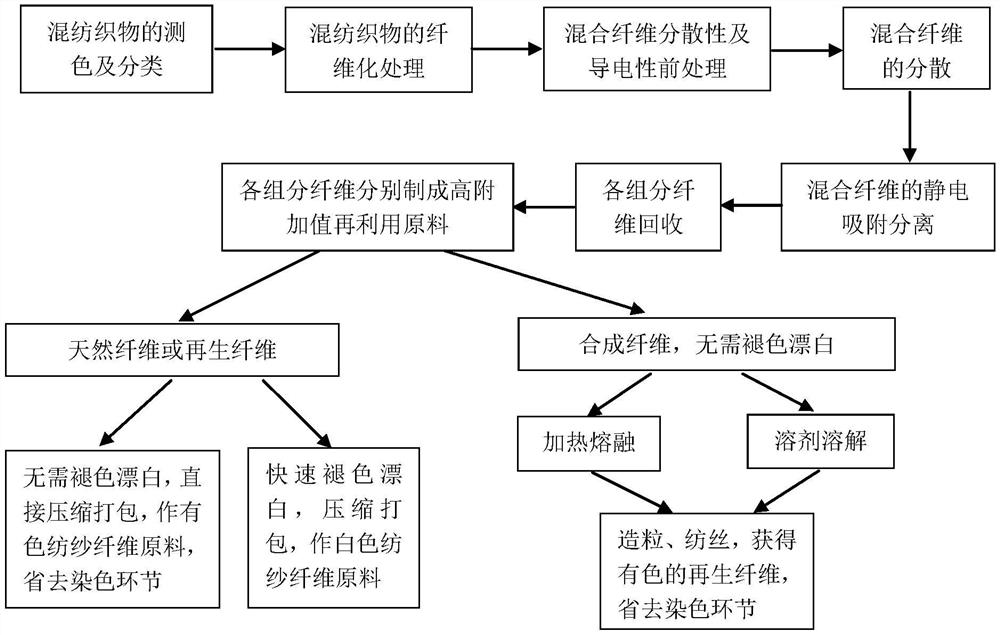

Method used

Image

Examples

Embodiment 1

[0027] The method for separating, recycling and reusing red polyester and viscose blended fabrics, the specific steps are as follows:

[0028] (1) Color measurement and classification, using a high-speed digital camera to collect images of polyester and viscose blended fabrics, converting them into HSV format, extracting hue, and then classifying polyester and viscose blended fabrics according to the hue.

[0029] (2) Fibrillation treatment. The polyester and viscose blended fabrics are fibrillated by mechanical hooking, and the classified polyester and viscose blended fabrics are disassembled into evenly dispersed polyester and viscose blended fibers.

[0030] (3) Dispersion and conductivity pretreatment, take 1g of polyester and viscose mixed fiber (after measurement, polyester accounts for 50% in the mixed fiber, viscose accounts for 50%, and the degree of separation is 1), according to the following components and weight Percentage: Water (92%), sodium silicate (2%), sodiu...

Embodiment 2

[0035] The method for separating, recycling and reusing blue polyester and cotton blended fabrics, the specific steps are as follows:

[0036] (1) Color measurement and classification, using a high-speed digital camera to collect images of polyester and cotton blended fabrics, converting them into HSV format, extracting hue, and then classifying polyester and cotton blended fabrics according to the hue.

[0037] (2) Fibrillation treatment. The polyester and cotton blended fabrics are fibrillated by mechanical hooking, and the classified polyester and cotton blended fabrics are disassembled into evenly dispersed polyester and cotton blended fibers.

[0038] (3) Dispersion and conductivity pretreatment, take 1 g of polyester and cotton blended fiber (after measurement, polyester accounts for 65% in the blended fiber, cotton accounts for 35%, and the degree of separation is 1.86), according to the following components and weight percentages: Water (35%), sodium silicate (30%), so...

Embodiment 3

[0043] Gray acrylic fiber and wool blended fabric separation recycling method, concrete steps are as follows:

[0044] Step (1) to step (5) compared with Example 1, the difference is: the blended fabric is gray acrylic fiber and wool blended fabric (after measuring, acrylic fiber accounts for 70%, wool accounts for 30%, and the degree of separation is 2.3); The components and percentages by weight of the dispersibility and conductivity treatment liquid that step (3) adopts are water (56%), sodium silicate (20%), sodium chloride (8%), electrolytic agent B (8%) , dispersant T (8%), the treatment conditions are: temperature 60 ℃, bath ratio 35:1, time 20min; Step (4) disperses, adopts mechanical vibration method, acrylic fiber and wool mixed fiber are dispersed into uniform thin layer; Step In (5), the distance between the two plates is 80cm, the voltage is 10000V and the electrification time is 50s. Other processes are the same as in Example 1.

[0045] Step (6) is reclaimed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com