Preparation of buoyancy material of integral forming process

A technology of composite materials and filling materials, applied in the direction of coating, etc., can solve the problems of large heat release and complex process of large-size floating bodies, and achieve the effect of excellent performance, consistent performance, and uniform curing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

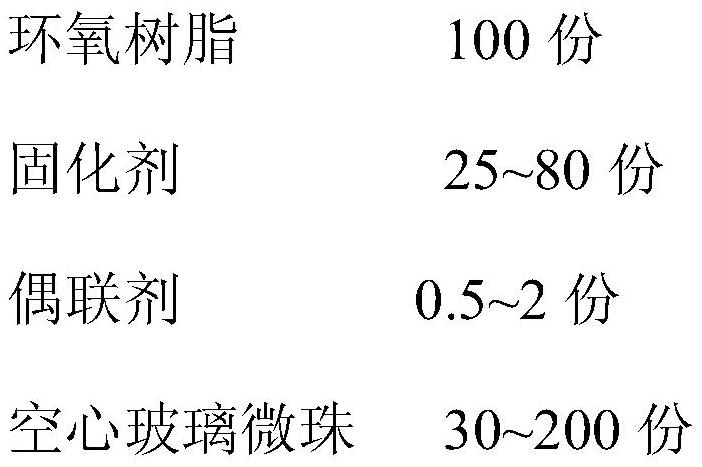

Method used

Image

Examples

Embodiment 1

[0024] Preparation of semi-cylindrical buoyancy material:

[0025] (1) VS5500 hollow glass beads were treated with KH-560 coupling agent. Mix the coupling agent and anhydrous ethanol evenly, the mass fraction of the coupling agent is 10-20wt%, then add the selected hollow glass microbeads into the ethanol solution of the coupling agent in the proportion of 1wt%, go through reflux washing, suction filtration and washing After a series of operations such as drying, the modified hollow glass microspheres are obtained.

[0026] (2) Add the weighed E-51 resin, polyamide 300# curing agent and JX-017 diluent into the vacuum mixer according to the mass ratio of 100::70:2, and the vacuum stirring time at room temperature is 5min. The liquid was stirred evenly and the foam was removed, and then the weighed modified hollow glass microspheres (180 parts) were added, and the vacuum stirring was continued for 10 min under normal temperature conditions.

[0027] (3) Fill the mixed and vacu...

Embodiment 2

[0032] Preparation of hemispherical floating body (diameter 60cm)

[0033] The raw materials and processes of Example 2 are basically the same as those of Example 1. The differences are as follows: (1) The hemispherical floating body is filled in two steps. (2) The hollow glass microspheres used are HGS8000X, and the mass fraction relative to the epoxy resin is 150 parts.

[0034] For the hemispherical floating body prepared in this example, the mass of the buoyant material is measured by an electronic scale, and the corresponding volume is obtained by measuring the size of the buoyant material with a caliper and a tape measure, and the calculated density is 0.53 g / cm 3 , the water absorption rate was 0.42% under 30MPa hydrostatic pressure for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com