Rapidly degradable antibacterial plastic film and preparation method thereof

A plastic film, rapid degradation technology, applied in the field of antibacterial plastic film, can solve the problems of insufficient mechanical properties and antibacterial properties, and achieve the effects of good mechanical properties, antibacterial properties and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

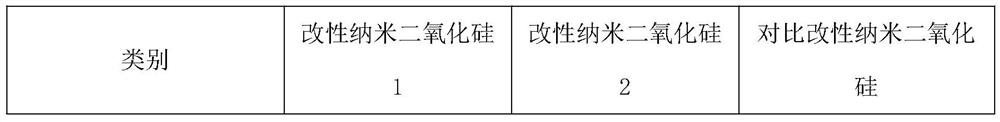

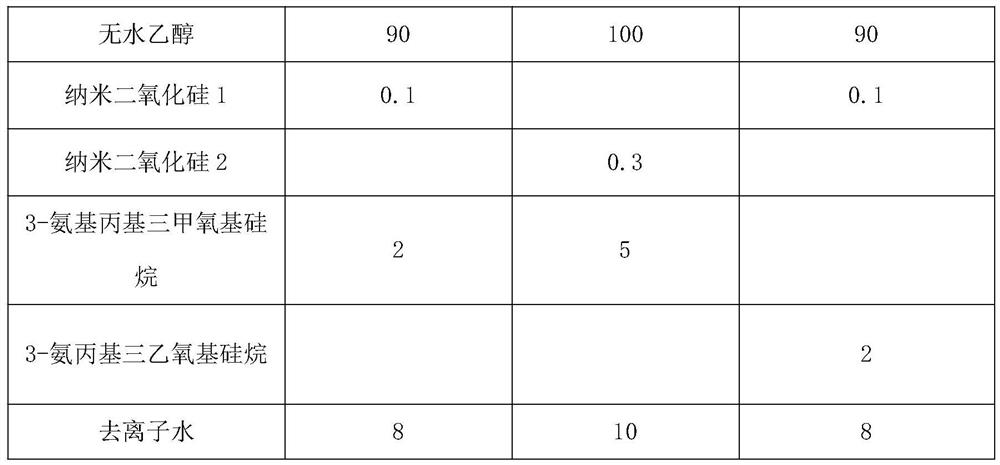

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of embodiment 1 plastic film comprises:

[0059] Step 1, adding 0.5 mass parts of nano-silica grafted graphene into 100 mass parts of chloroform, and dispersing by ultrasonic vibration for 2 hours to obtain a nano-silica grafted graphene dispersion;

[0060] Step 2, add 300 parts by mass of chloroform and 100 parts by mass of polylactic acid into the reactor, start stirring, add the aforementioned nano-silica grafted graphene dispersion after the polylactic acid is dissolved, and stir the mixture for 5 hours Coating film, after the volatilization of chloroform is completed, a plastic film is obtained.

Embodiment 2

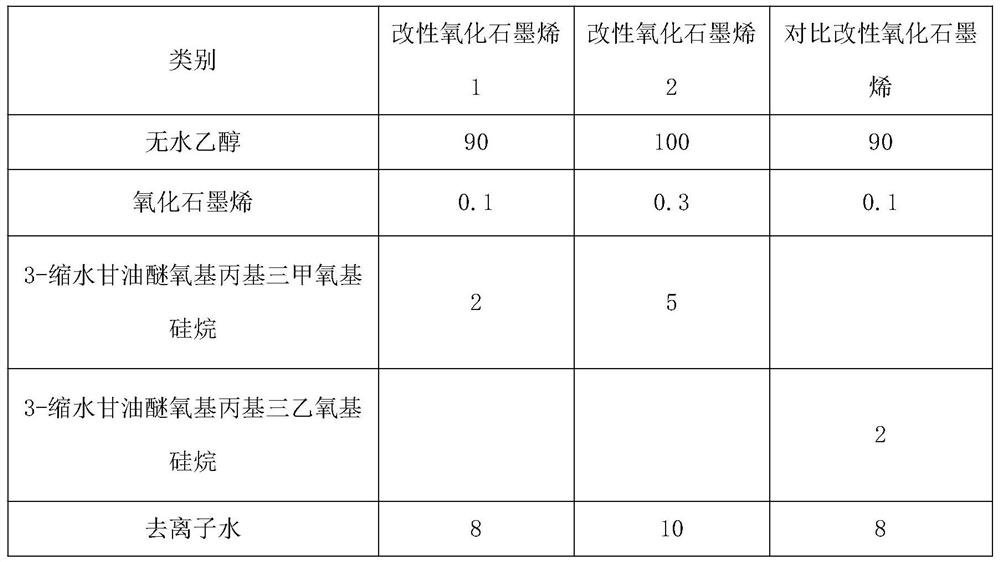

[0061] In the preparation method of the plastic film of Example 2 and Comparative Examples 1-6, different raw materials were carried out according to the types and dosages listed in Table 4, and other steps, raw materials, parameters, etc. were the same as the preparation method of Example 1.

[0062] The consumption (mass part) of table 4 embodiment and comparative example plastic film preparation method raw material

[0063]

[0064] The plastic film sample thickness that embodiment and comparative example obtain is about 0.15mm, and the test standard that carries out performance test is as follows:

[0065] 1. The antibacterial test standard is: QB / T 2591-2003, wherein, the pure polylactic acid film used in the test process, its polylactic acid raw material and film preparation method are consistent with the examples and comparative examples;

[0066] 2. The mechanical performance test standard is: GB / T 1040-2006.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com