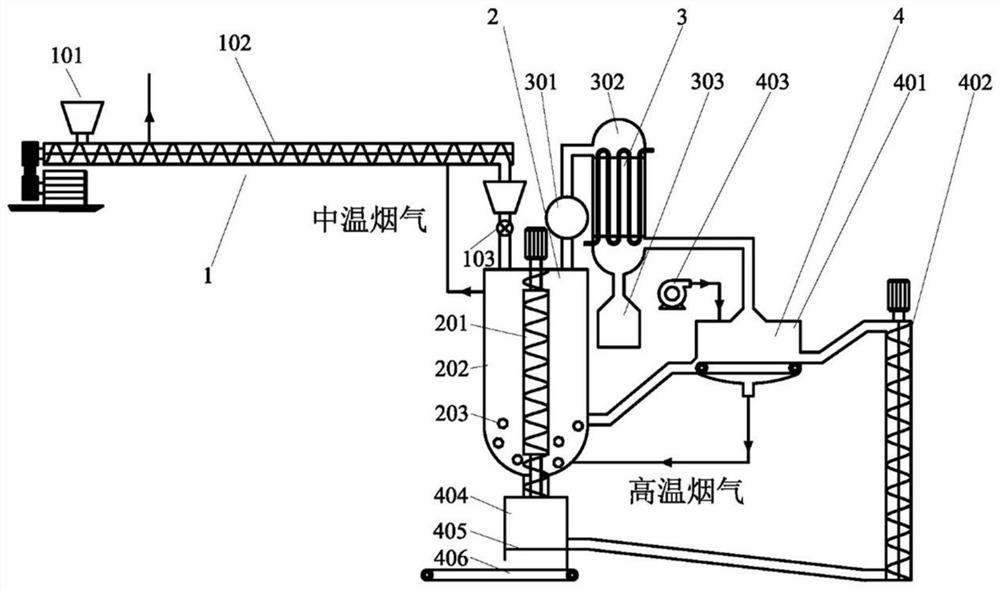

Waste plastic treatment system and method based on heat carrier double-circulation heat supply

A disposal system and technology for waste plastics, applied in the treatment of hydrocarbon oil, the preparation of liquid hydrocarbon mixtures, the petroleum industry, etc., can solve the problems of insufficient fluidity, easy coking and sticking to the wall, poor heat transfer, etc., to avoid coking on the wall, strengthen Heat transfer effect and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

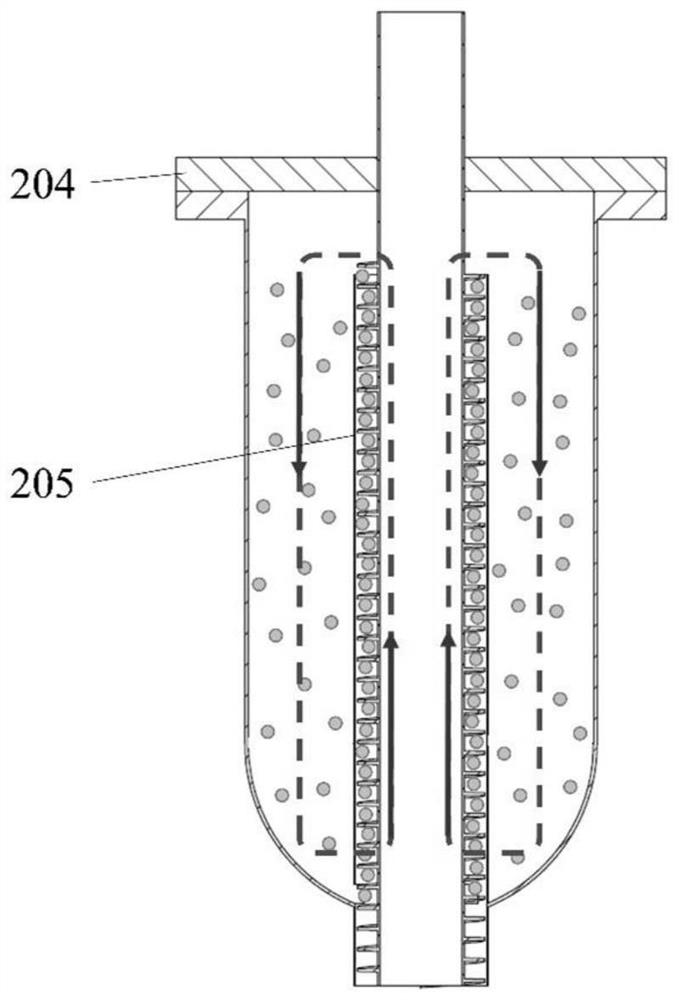

[0052] Waste plastics with a particle size of 2mm to 5mm enter the low-temperature dechlorination feeder at a temperature of 300°C to remove the acid gas whose main component is HCl; the remaining raw materials enter the internal circulation reactor for pyrolysis reaction, and the temperature in the internal circulation reactor is 480℃; heat carrier with Ni catalyst on the surface (Al 2 o 3 ) falls into the viscous molten plastic from the top of the pyrolysis furnace, realizing direct contact heat transfer and in-situ catalytic reaction, and efficiently catalyzing the pyrolysis of the plastic; when the heat carrier sinks into the bottom of the pyrolysis furnace, it is transported by the screw To the top of the reactor, the raised balls fall again to achieve enhanced heat transfer, and the continuous operation of the device can repeat the above process; due to the irregular form of the heat carrier, the coke on the wall can be scraped off during the falling process; at the end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com