A kind of anti-hydrogen-induced cracking X80 pipeline steel for marine use and its manufacturing method

A technology of anti-hydrogen-induced cracking and manufacturing method, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of high hydrogen-induced cracking resistance and deep-sea application, etc., and achieve excellent anti-HIC performance, inhibiting Effects of Diffusion and Segregation, Increased Crack Growth Resistance and Grain Boundary Cracking Difficulty

Active Publication Date: 2022-07-26

WUHAN UNIV OF SCI & TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the high hydrogen-induced cracking resistance marine pipeline steels involved in the existing technology are mainly low-grade pipeline steels with low strength, such as X70 and X65 steel grades, etc. There is no technology involving high-steel grade marine pipelines of X80 and above steel; while the X80 pipeline steel technology involving high strength and high toughness pipeline steel does not mention high hydrogen-induced cracking resistance and deep-sea applications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

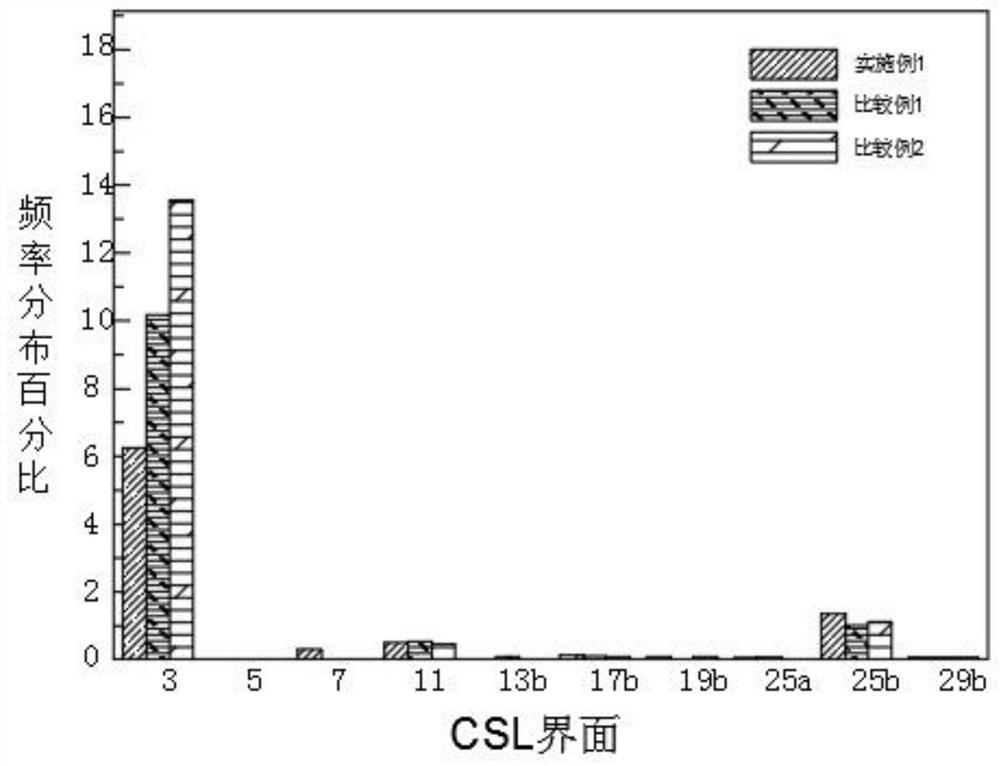

[0049] Example 1 and Comparative Example 1: After rough rolling, the aerosol was cooled to 960° C., and then slowly cooled to 920° C. for heat preservation treatment for 15 minutes, and the total duration of slow cooling and heat preservation treatment was 25 minutes;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

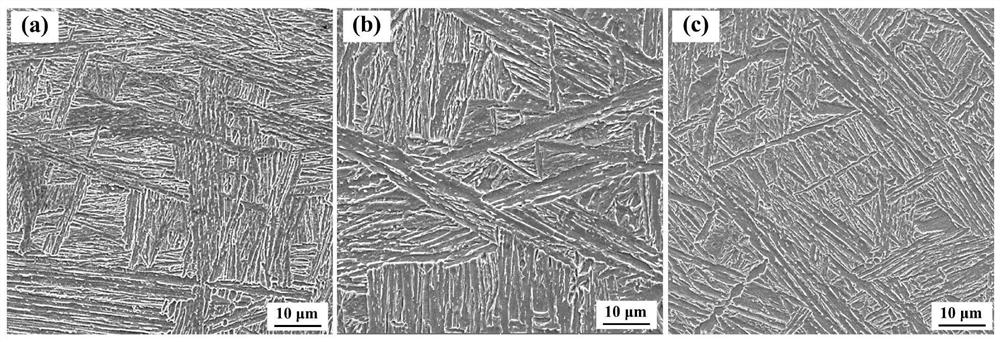

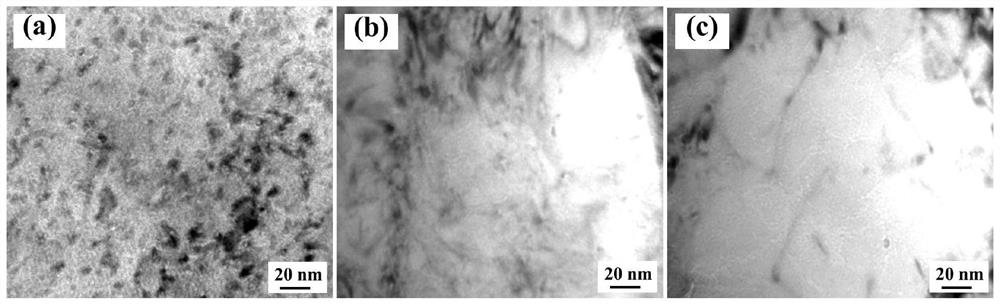

The invention discloses an X80 grade pipeline steel with resistance to hydrogen-induced cracking for marine use and a manufacturing method thereof, and relates to the technical field of steel for marine engineering. The pipeline steel of the invention includes C: 0.05-0.07%, Si: 0.24~0.30%, Mn: 1.75~1.95%, S: ≤0.003%, P: ≤0.005%, Cu: 0.20~0.30%, Ni: 0.25~0.30%, Mo: 0.22~0.27%, Ta: 0.03~0.06 %, N: 0.005-0.01%, the balance is Fe; the chemical composition mass percentages of Ta and N meet 6≤Ta / N≤9, and the manufacturing process of the present invention includes: batching, smelting and casting into a billet-casting billet and reheating- Rough rolling-aerosol cooling and slow cooling-finishing-coiling; the present invention forms dispersed tantalum carbide precipitation in the steel by adding an appropriate amount of Ta element, controlling the Ta / N ratio, and the process of mist cooling and slow cooling after rough rolling. , and refine the granular bainite matrix and reduce the Σ3 interface ratio to achieve both high strength, high toughness and excellent hydrogen-induced cracking resistance.

Description

technical field [0001] The invention relates to the technical field of steel for marine engineering, in particular to an X80 grade pipeline steel with resistance to hydrogen-induced cracking for marine use and a manufacturing method thereof. Background technique [0002] In recent years, my country's marine economy has developed rapidly. With the large-scale exploration and development of deep-water oil and gas fields in the South my country Sea, the application scale of high-strength pipeline steel for deep-sea oil and gas transportation will expand rapidly. The development and production of submarine pipeline steel in my country began in 2004. So far, Baosteel, Anshan Iron and Steel, Wuhan Iron and Steel have developed and produced X70 and below-grade submarine special pipeline steel, which has been applied in shallow sea environment, and deep-sea pipeline steel with X70 and higher grades has been developed. still in its infancy; [0003] At present, the high hydrogen-indu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/08C22C38/12C22C38/16B21B3/02B21B37/58B21B37/74B21B45/02C21D8/02C22C33/04

CPCC22C38/02C22C38/04C22C38/16C22C38/08C22C38/12C22C38/001C21D8/0205C21D8/0221C22C33/04B21B3/02B21B37/74B21B37/58B21B45/0203C21D2211/002C21D2211/005

Inventor 张施琦刘静黄峰葛锐彭志贤

Owner WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com