Barrel-plating neutral tin plating process

A neutral, tin-plating technology, applied in the field of electroplating, can solve problems such as continuous sheeting and affecting product quality, and achieve the effect of improving hardness, reducing penetration and continuous sheeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

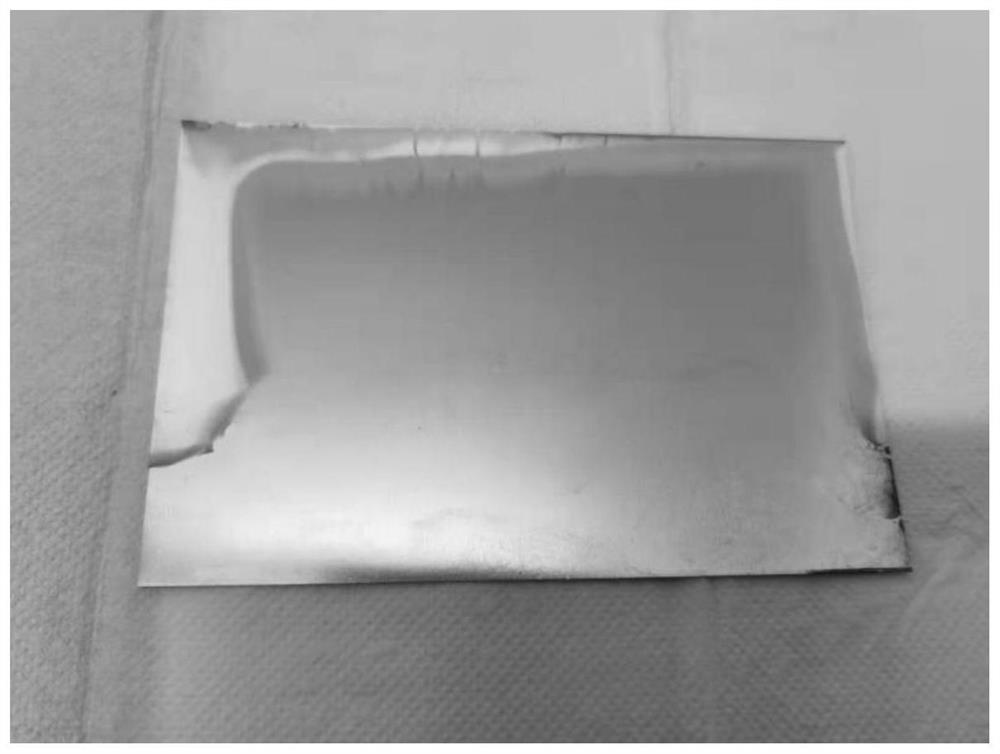

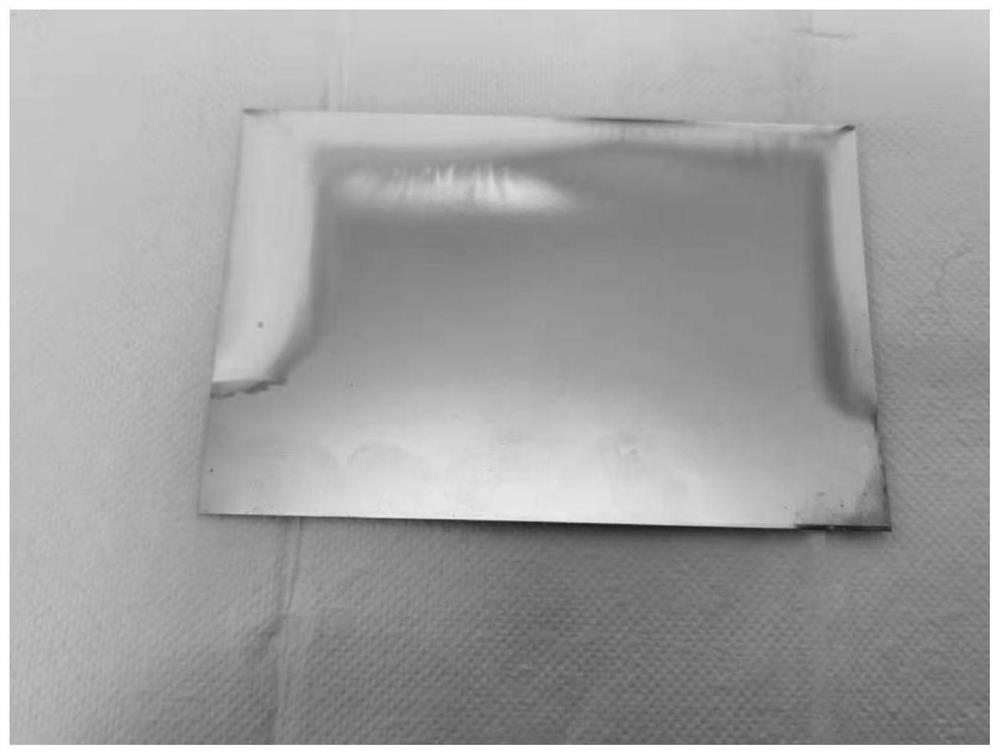

Image

Examples

Embodiment 1

[0031] The present embodiment provides a barrel plating neutral tin plating process, and the specific steps are as follows:

[0032] Neutral tin plating solution components: tin methanesulfonate 15g / L, ammonium citrate 80g / L, ammonium sulfate 50g / L, naphthol polyoxyethylene ether 0.5g / L.

[0033] Mix the components of the neutral tin plating solution according to the above ratio, adjust the pH of the plating solution to about 3.4, and then add tyrosine (0.3g / L), phenylalanine (0.3g / L), tryptophan to it (0.4g / L), alkyl glycoside APG1214 (0.3g / L) and polyvinyl alcohol (0.15g / L), then weigh 5kg of resistance product and put it into the drum, electroplate at constant current 48A for 2h, take out the product, and use The sieve separates the contiguous products, drying, weighing, and calculating the contiguous rate:

[0034] Consecutive rate = contiguous product quality / total product quality × 100%.

Embodiment 2

[0036] The present embodiment provides a barrel plating neutral tin plating process, and the specific steps are as follows:

[0037] Neutral tin plating solution components: tin methanesulfonate 15g / L, ammonium citrate 80g / L, ammonium sulfate 50g / L, naphthol polyoxyethylene ether 0.5g / L.

[0038] Mix the components of the neutral tin plating solution according to the above ratio, adjust the pH of the plating solution to about 3.4, and then add tyrosine (0.4g / L), phenylalanine (0.4g / L) and BNO12 (0.2g / L) to it. g / L), then weigh 5kg of resistance product into the drum, electroplate at constant current 48A for 2h, take out the product, use a sieve to separate the contiguous product, dry it, weigh the weight, and calculate the contiguous rate.

Embodiment 3

[0040] The present embodiment provides a barrel plating neutral tin plating process, and the specific steps are as follows:

[0041] Neutral tin plating solution components: tin methanesulfonate 15g / L, ammonium citrate 80g / L, ammonium sulfate 50g / L, naphthol polyoxyethylene ether 0.5g / L.

[0042] Mix the components of the neutral tin plating solution according to the above ratio, adjust the pH of the plating solution to about 3.4, then add tryptophan (1.2g / L) and polyvinylpyrrolidone (0.1g / L) to it, then weigh 5kg The resistance product is put into the drum, and the constant current 48A is electroplated for 2 hours. The product is taken out, and the contiguous product is separated by a sieve, dried, weighed, and the contiguous rate is calculated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com