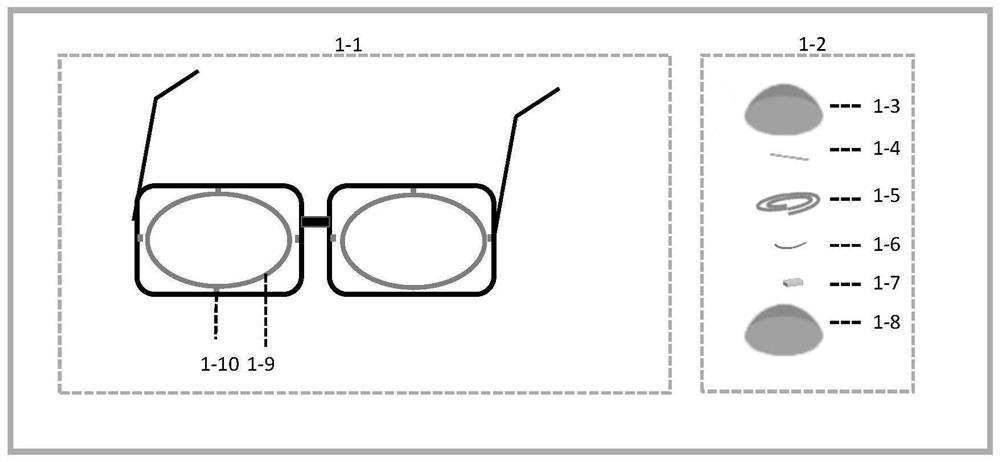

Flexible multifunctional corneal contact lens based on gamma-Fe2O3@NiO magnetic oxide nanosheets

A contact lens and magnetic oxide technology, applied in glasses/goggles, diagnostic recording/measurement, eye testing equipment, etc., to achieve outstanding reliability and stability, easy mass production, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A γ-Fe based 2 o 3 A method for preparing a flexible multifunctional contact lens of @NiO magnetic oxide nanosheets, comprising the following steps:

[0045] Step 1. Synthesis of γ-Fe by one-step hydrothermal method 2 o 3 @NiO magnetic oxide nanosheets, the specific process is:

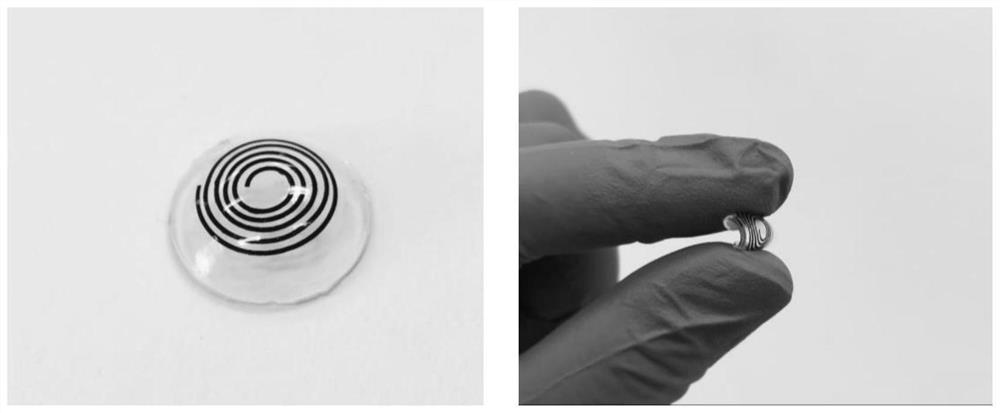

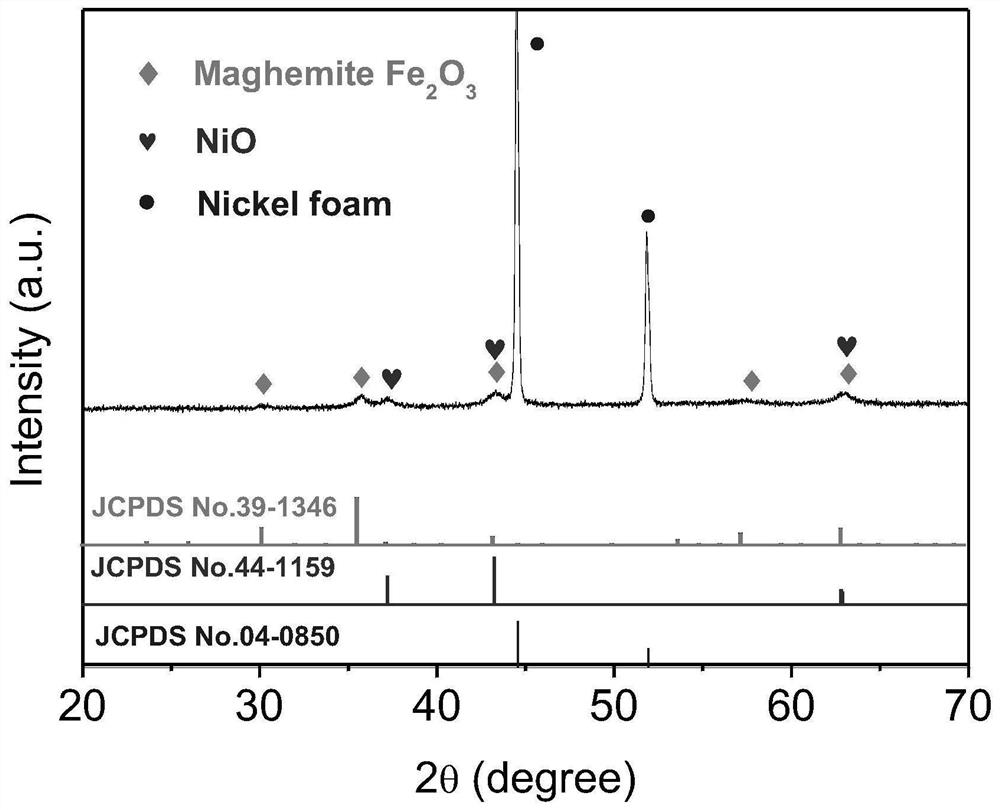

[0046] Add 0.1mol Fe(NO 3 ) 3 9H 2 O, 0.1mol Ni(NO 3 ) 3 9H 2 O and 1mm olCH 4 N 2 0, after being stirred evenly, transfer in the 50mL autoclave, put the foamed nickel (2*3cm) that has been pretreated into the above-mentioned autoclave simultaneously, react at a constant temperature at a temperature of 120°C for 6 hours, naturally cool to room temperature after the reaction finishes, Then take it out and rinse it several times with deionized water, and dry it overnight in a vacuum oven at 60°C to get γ-Fe on the surface of foamed nickel. 2 o 3 @NiO magnetic oxide nanosheets; the X-ray diffraction pattern of the nanosheets is as follows image 3 The scanning electron microscope ima...

Embodiment approach

[0062] Figure 8 It is a confocal microscope image of the multifunctional contact lens inner layer microfluidic channel encapsulation film provided by the embodiment of the present invention. It is only a specific implementation mode. All inner layer encapsulation films (1-8) with microfluidic channels can Realize tears passing through the inner packaging film (1-8) and reference electrode (1-4), counter electrode (1-6) and γ-Fe 2 o 3 The design of the @NiO magnetic oxide nanosheet sensing layer (1-5) contacts are all within the scope of protection. Such as Figure 8 As shown, where (8-1) is the tear inlet, (8-2) is the tear outlet, the microfluidic channel is mainly composed of a serpentine channel, a quasi-circular channel and an electrode layer setting area, and the line width is 300 μm. The serpentine design helps to collect tears, so that the tears completely wet the magnetic oxide nanosheet sensing layer, reference electrode and counter electrode. (8-3) is the refere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com