Piezoelectric resonator and manufacturing method thereof

A piezoelectric resonator and piezoelectric layer technology, applied in the field of piezoelectricity, can solve the problems of acoustic energy loss, associated lateral clutter leakage, increased filter band ripple and insertion loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

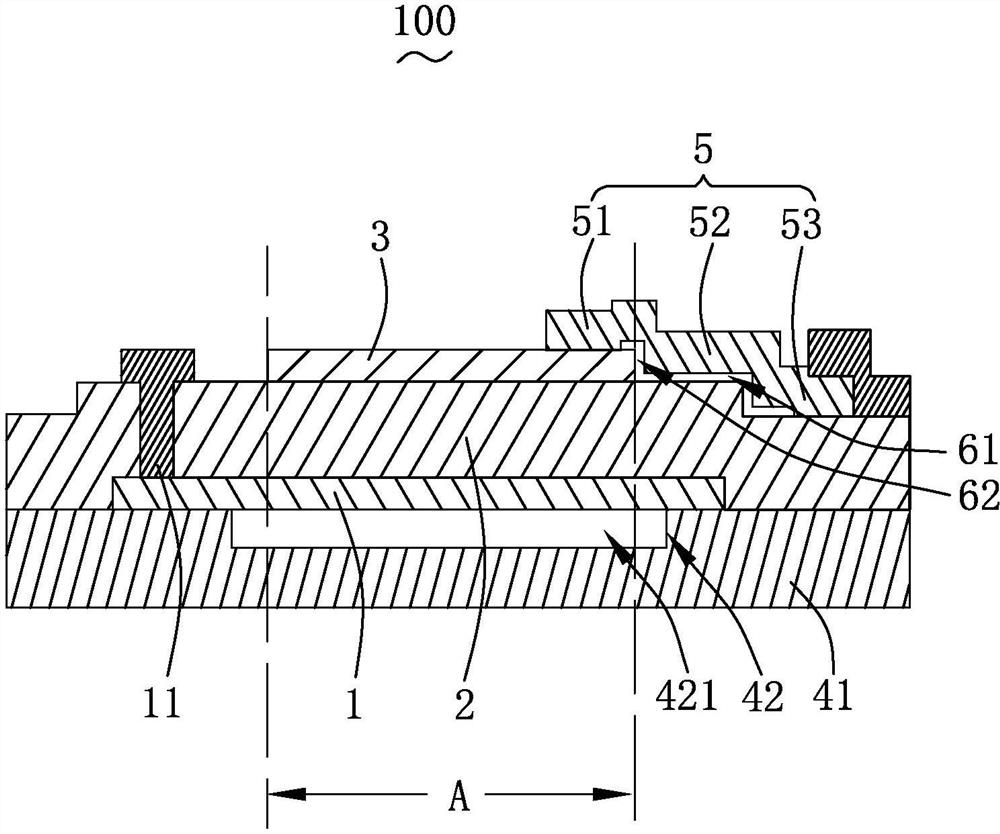

[0052] see figure 1 , is a structural schematic diagram of Embodiment 1 of the piezoelectric resonator of the present invention. The present invention provides a piezoelectric resonator 100 , comprising: a bottom electrode 1 , a piezoelectric layer 2 , a top electrode 3 , an acoustic wave reflection layer structure 42 , and a top electrode lead-out structure 5 .

[0053] The piezoelectric layer 2 is stacked on the bottom electrode 1 .

[0054] The top electrode 3 is stacked on a side of the piezoelectric layer 2 away from the bottom electrode 1 .

[0055] The acoustic wave reflection layer structure 42 is formed on a side of the bottom electrode 1 away from the piezoelectric layer 2 . That is, the acoustic wave reflection layer structure 42 is formed under the top electrode 3 , the piezoelectric layer 2 and the bottom electrode 1 .

[0056] The top electrode lead-out structure 5 is located on the side of the piezoelectric layer 2 away from the bottom electrode 1 .

[0057]...

Embodiment approach 2

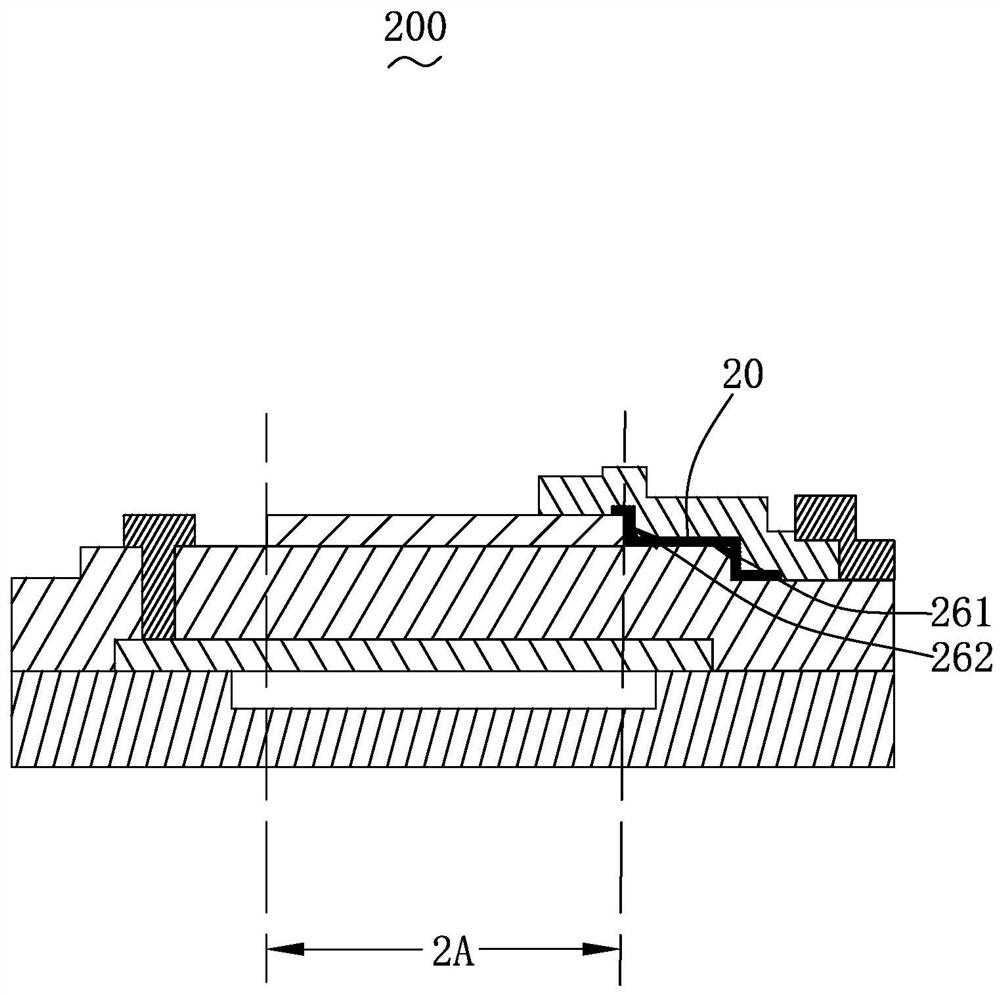

[0069] The present invention also provides another implementation mode, please combine figure 2 Shown is a schematic structural diagram of Embodiment 2 of the piezoelectric resonator of the present invention. The structure of the piezoelectric resonator 200 is basically the same as that of the first embodiment above, except that:

[0070] The second air gap 262 is filled with a functional material 20, which can isolate the bridge structure from the top electrode, realize the reflection of sound waves, reflect the sound wave energy back to the resonance area, and prevent part of the transverse clutter from passing through the The region leaks out of the resonance region 2A, thereby improving the Q value of the piezoelectric resonator 200 .

[0071] The first air gap 261 is filled with functional materials 20, which can reduce the area of the non-resonant region and reduce the problem of reducing the effective electromechanical coupling coefficient caused by parasitic capaci...

Embodiment 3

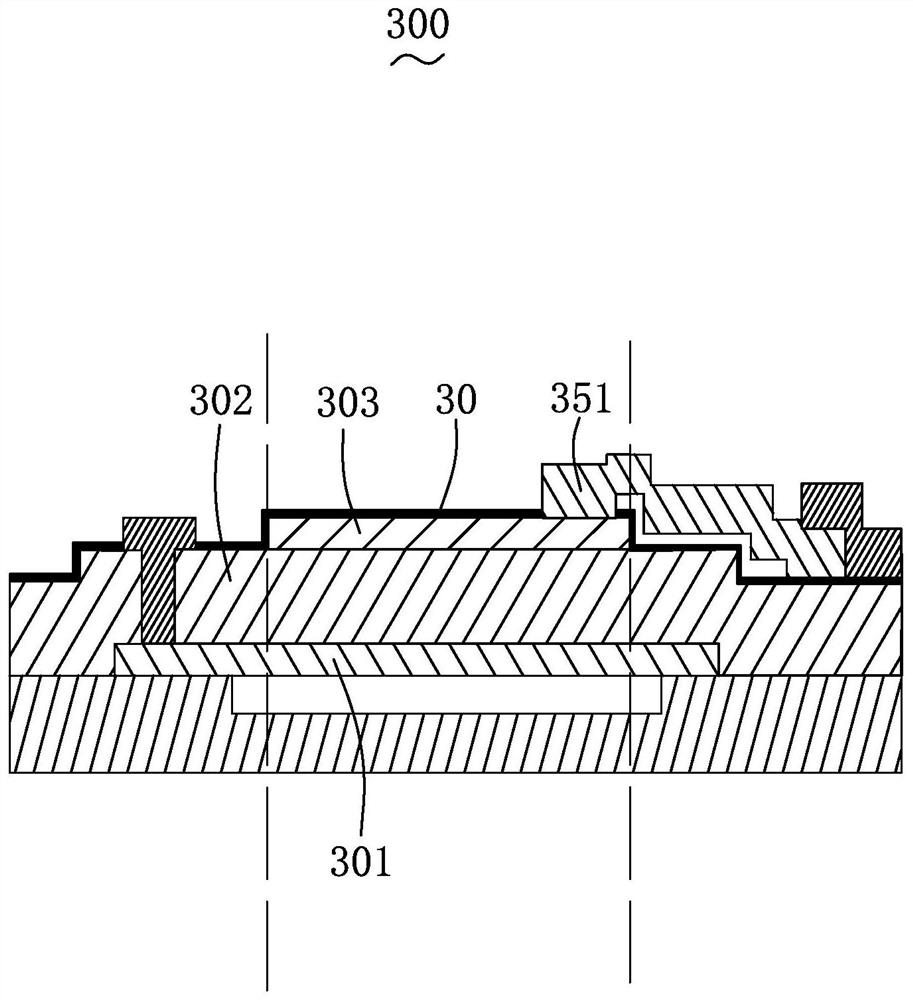

[0075] The present invention also provides another implementation mode, please combine image 3 Shown is a schematic structural diagram of Embodiment 3 of the piezoelectric resonator of the present invention. The structure of the piezoelectric resonator 300 is basically the same as that of the first embodiment above, except that:

[0076] The piezoelectric resonator 300 further includes a passivation layer 30 . The passivation layer 30 is stacked on a side of the top electrode 303 away from the piezoelectric layer 302 and at least partially covers the top electrode 303 . Of course, the electrode connection end 351 needs to penetrate the passivation layer 30 and be connected to the top electrode 303 .

[0077] However, the arrangement of the purification layer 30 can effectively protect the top electrode 303 and the piezoelectric layer 302 and improve structural reliability.

[0078] Except for the above differences, its structure is the same as that of Embodiment 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com