Preparation method and application of porous plant particles with scorch aroma

A technology of plant granules and burnt aroma, which is applied in the field of preparation of porous plant granules, can solve the problems of no synergy, the amount of adsorption needs to be improved, and the difficulty of industrial production, so as to achieve the effect of aroma improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

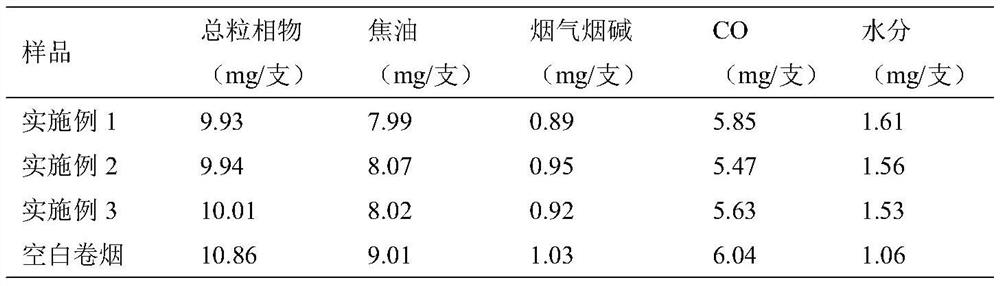

Embodiment 1

[0022] (1) Fresh ginger, hawthorn, black plum, licorice, malt are removed from impurities, sliced, and sieved to remove debris; when placed in a 65°C oven and dried to a water content of 7wt%, then pulverize to make the particle size of the plant particles: 1.5-2.0mm, save for future use;

[0023] (2) The plant granules obtained in step (1): ginger, hawthorn, black plum, licorice, and malt are mixed evenly according to the ratio of mass percentage 20%: 20%: 10%: 20%: 30%, and are separated from the air at 700 ° C. Stay for 1.5 seconds;

[0024] (3) cooling the particles obtained in step (2) to room temperature in isolation from air;

[0025] (4) Pulverize the particles obtained in step (3) to a powder with a particle size of 150 mesh. Weigh 100g powder, 8g binder (gelatin and sodium carboxymethyl starch composite binder with a mass ratio of 1:1), add 300mL distilled water to fully mix the binder and raw materials, prepare slurry, and granulate for 45 minutes , the material ...

Embodiment 2

[0027] (1) Fresh ginger, hawthorn, licorice, rose petals, and buckwheat are removed from impurities, sliced, and sieved to remove debris. Place in an oven at 65°C and dry until the water content reaches 10wt%, then pulverize the plant particles so that the particle size is 1.0-1.5mm, and store them for later use;

[0028] (2) The plant particles obtained in step (1): ginger, hawthorn, licorice, rose petals, buckwheat, mixed evenly according to mass percentage 10%: 10%: 20%: 30%: 30%, at 600 ° C under the isolation of air stay for 2 seconds;

[0029] (3) cooling the particles obtained in step (2) to room temperature in isolation from air;

[0030] (4) Pulverize the particles obtained in step (3) to a powder with a particle size of 120 mesh. Weigh 100g of powder, 6g of binder (gelatin and sodium carboxymethyl starch composite binder with a mass ratio of 1:1), add 300mL of distilled water, fully mix the binder and raw materials evenly, prepare the slurry, and the granulation ti...

Embodiment 3

[0032] (1) Remove impurities, slice and sieve fresh lotus pods, bamboo leaves, licorice, rose petals, and honeysuckle to remove debris. Place in an oven at 65°C and dry until the water content reaches 10wt%, then pulverize the plant particles so that the particle size is 1.0-1.5mm, and store them for later use;

[0033] (2) The plant particles obtained in step (1): lotus pods, bamboo leaves, licorice, rose petals, honeysuckle, mixed evenly according to mass percentage 20%: 10%: 20%: 20%: 30%, and insulated at 800 ° C Stay under air for 1 second;

[0034] (3) cooling the particles obtained in step (2) to room temperature in isolation from air;

[0035] (4) The granules obtained in step (3) are pulverized into powders with a particle size of 130 meshes; 100g of powder and 4g of binder (gelatin and sodium carboxymethyl starch composite binder with a mass ratio of 1:1) are weighed, added 300mL of distilled water was used to fully mix the binder and raw materials evenly, and prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com