Preparation method and application of titanium-oxygen material

A technology of titanium oxide compounds and raw materials, applied in the field of preparation of titanium-oxygen materials, can solve the problems of high equipment requirements, difficulty in controlling the content and distribution of oxygen vacancies, and high cost of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

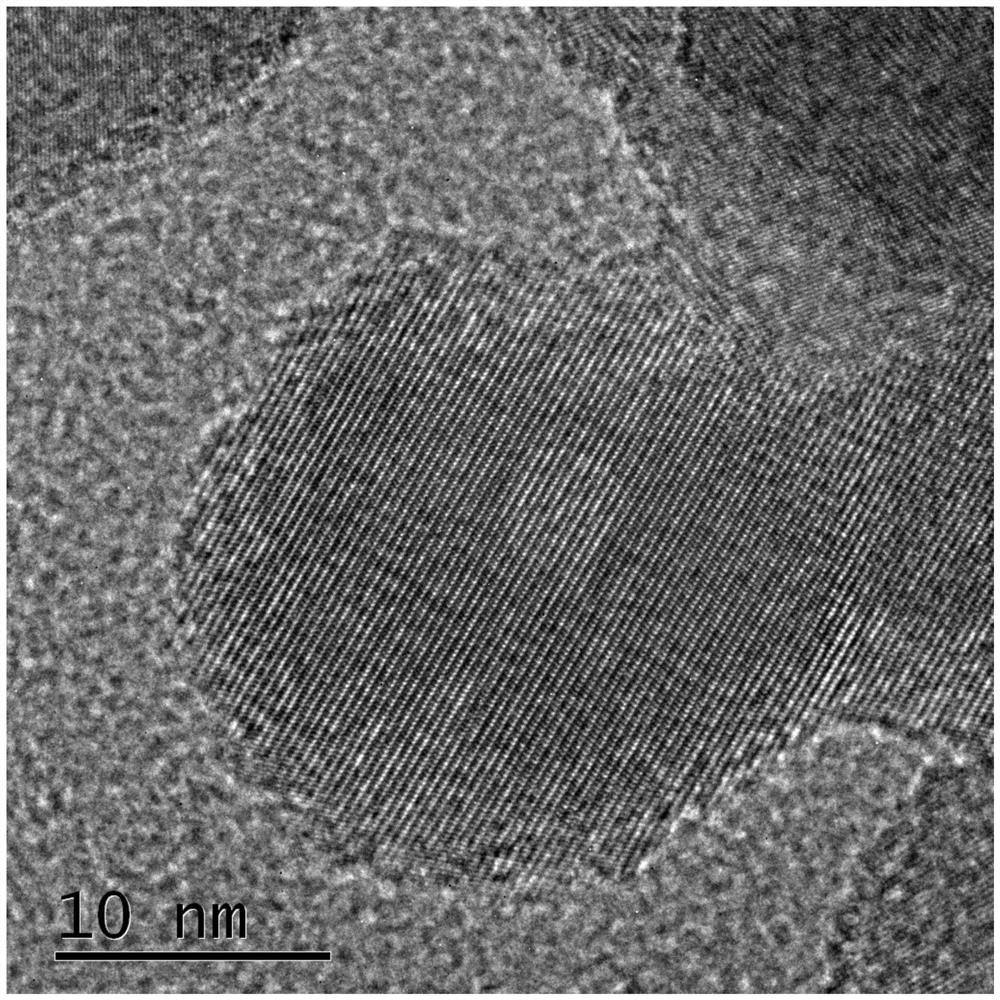

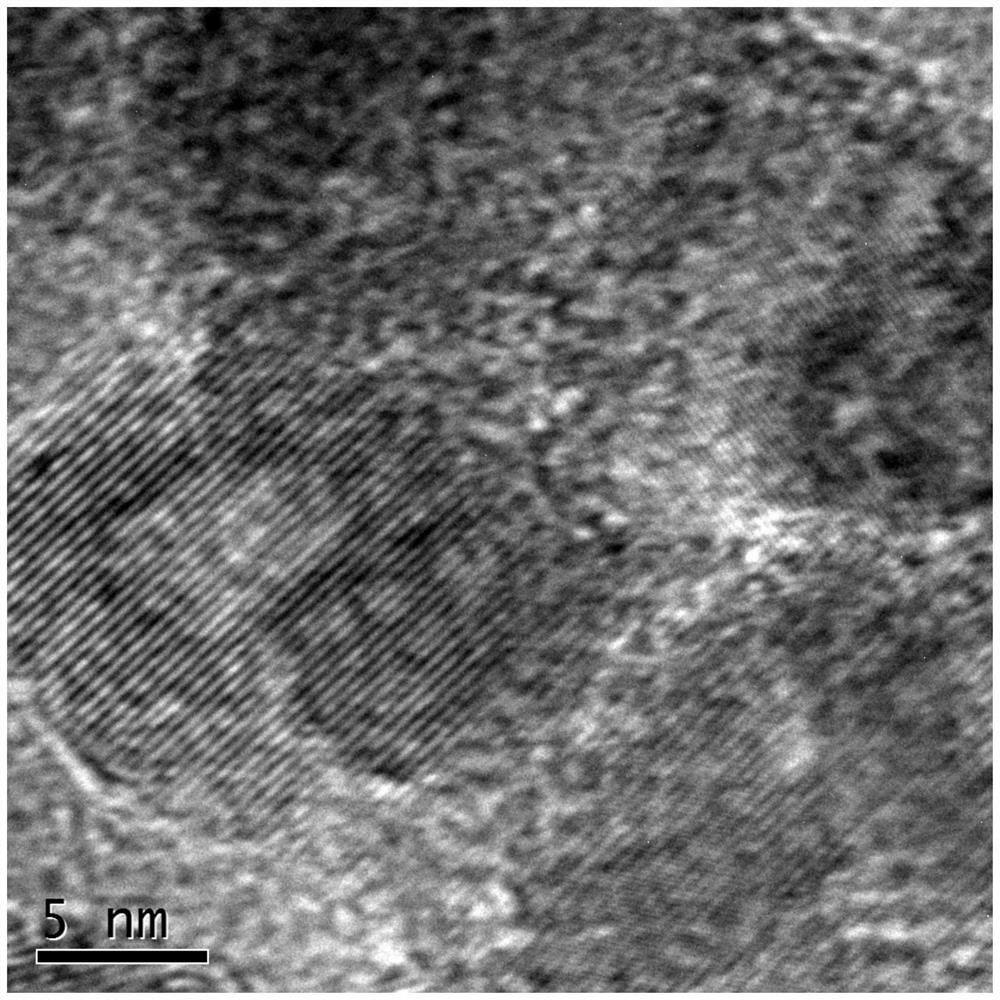

[0078] In this embodiment, a titanium-oxygen material is prepared, and the specific process is as follows:

[0079] A1. Weigh 0.2g TiO 2 (10-25nm) into 40ml ethanol-water mixture with a volume ratio of 70% ethanol, ultrasonic for 30min;

[0080] A2. Pass N into the mixture obtained in step A1 2 , to exclude the oxygen dissolved in it, and seal it;

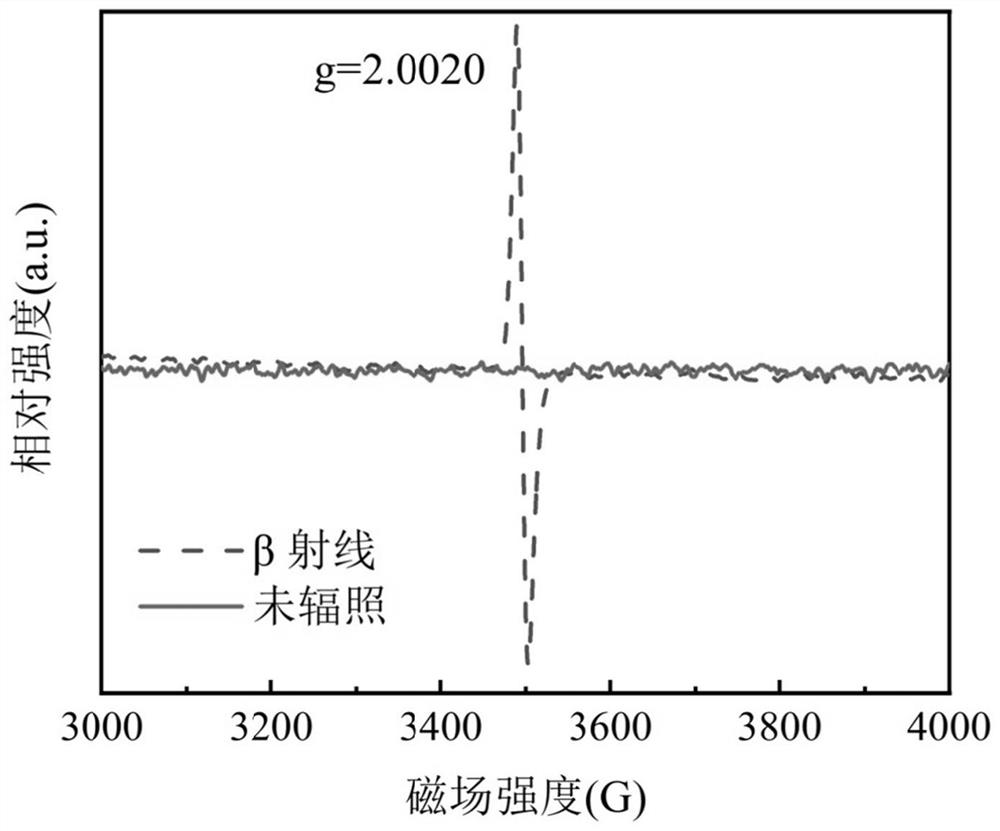

[0081] A3. Put the mixture obtained in step A2 into a beta ray radiation field, and accept a dose of 60.6kGy of radiation;

[0082] A4. Put the mixture obtained in step A3 into a gamma ray radiation field, and accept a dose of 30.6kGy of radiation;

[0083] A5. The solid product obtained in step A4 was repeatedly washed with ethanol and deionized water, and dried in vacuum to obtain a titanium-oxygen material. Examples 2-4 and Comparative Examples 1-6 respectively prepared a titanium-oxygen material, the specific difference from Example 1 is that the type of radiation field used in steps A3-A4 and the radiation dose received ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com