Self-cleaning device for monitoring camera lens of coal mine haulage roadway

A surveillance camera and self-cleaning technology, applied in the fields of dust removal, image communication, cleaning methods and utensils, etc., can solve the problems of difficult to clean the lens on demand, high maintenance cost, low dust recognition reliability, etc., to reduce dust misjudgment The probability, efficiency and reliability are improved, and the effect of easy self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

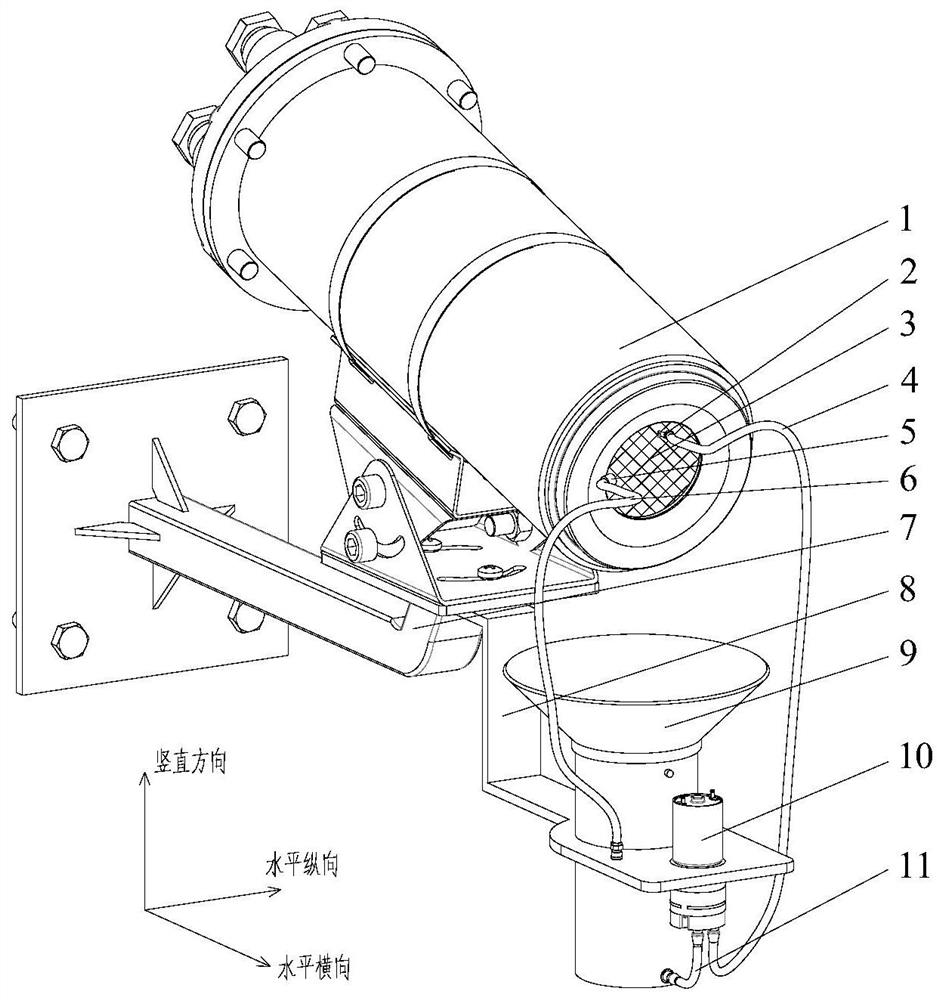

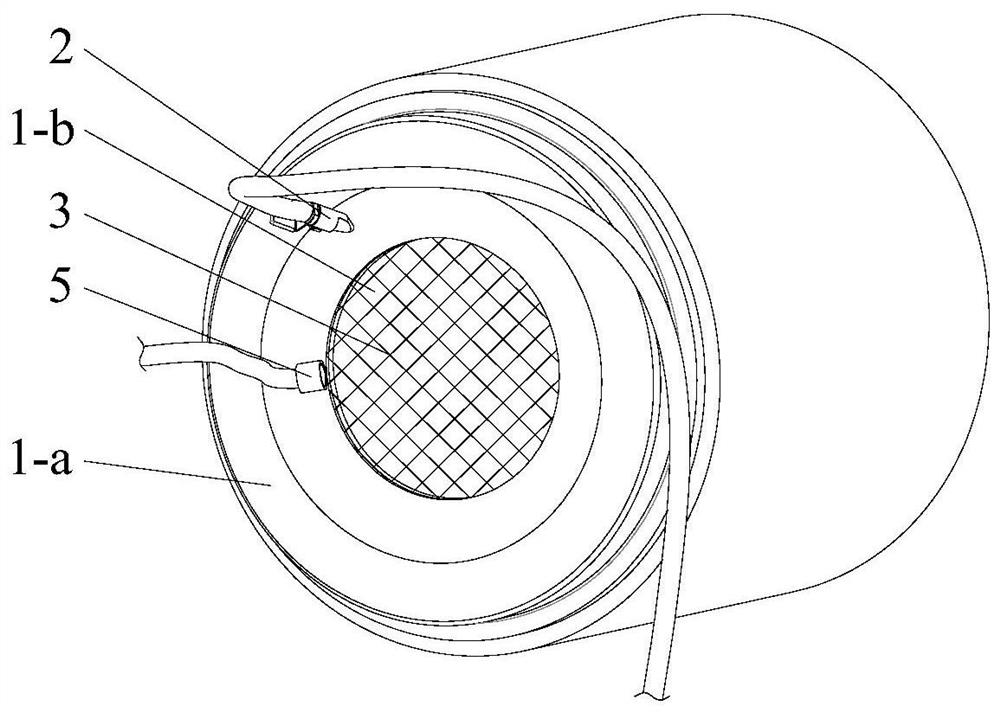

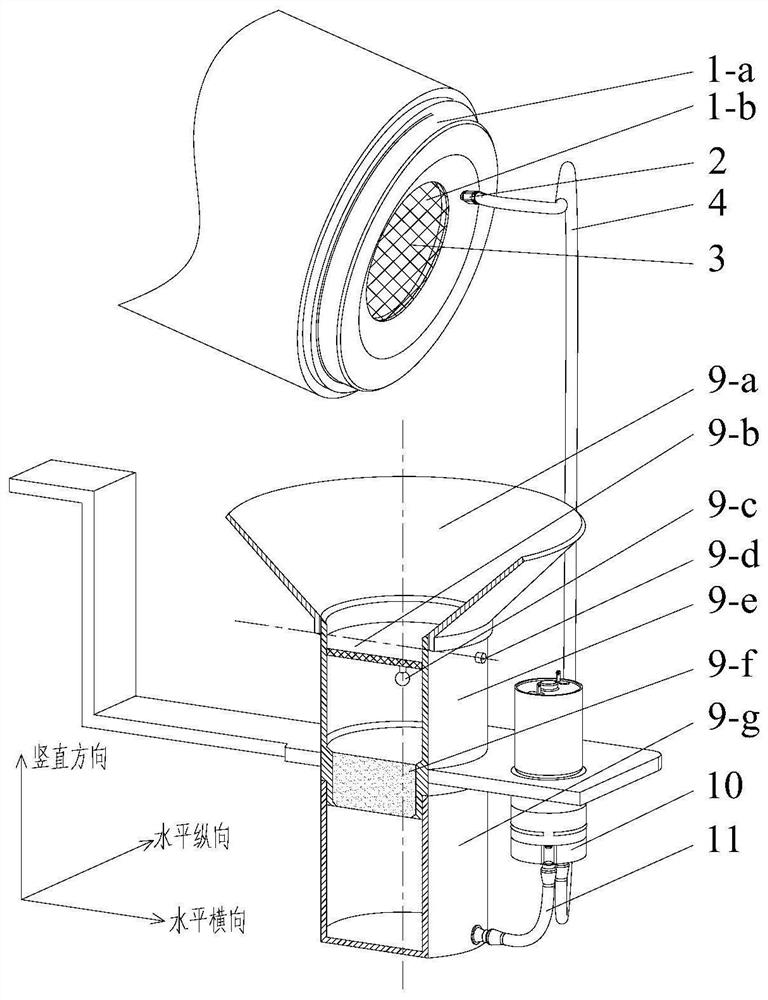

[0017] like figure 1 As shown, the lens self-cleaning device of the coal mine transportation roadway monitoring camera of the present invention is mainly composed of a support 8, a water circulation module 9, an explosion-proof water pump 10, a universal metal water spray pipe 4, an adjustable narrow-angle flat nozzle 2, a magnesium-aluminum alloy soft Tube 6, two-color spotlight 5, water inlet pipe 11 and light-transmitting hydrophobic film 3 constitute. like image 3 As shown, the water circulation module 9 is composed of a funnel 9-a, a flap 9-b, a weight 9-c, a pin 9-d, a water storage chamber 9-e, activated carbon 9-f and a water purification chamber 9- g composition. One end of the support 8 is fixed on the camera bracket 7, and the other end of the support 8 close to the lens 1-b is vertically provided with a water circulation module 9 and an expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com