High-purity barium metaphosphate and preparation method thereof

A technology of pure barium metaphosphate and barium carbonate, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of increased production cost, complex production process, and high production cost of barium metaphosphate, and achieves small investment in equipment, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

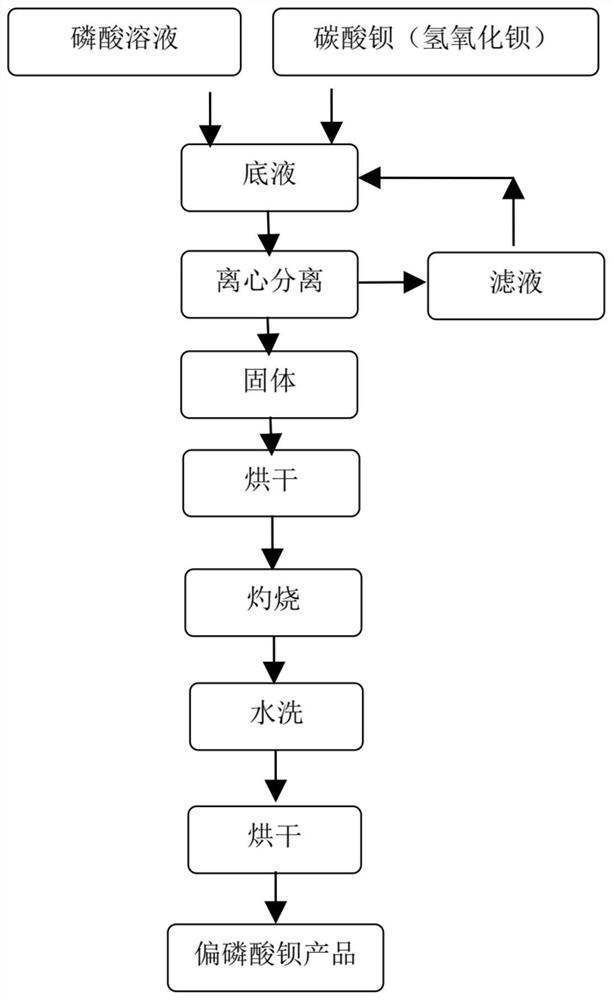

[0028] Concrete, the preparation method of high-purity barium metaphosphate of the present invention comprises:

[0029] (1) add phosphoric acid solution as bottom liquid in reactor, and heat;

[0030] (2) get phosphoric acid solution in addition, make it and barium carbonate slowly add in the described reactor in proportion, heat, stir, obtain solid and filtrate through solid-liquid separation after reaction finishes;

[0031] (3) adding the filtrate to the reactor as the bottom liquid for recycling, drying the solid, and then washing it with water after burning to constant weight;

[0032] (4) drying again to obtain high-purity barium metaphosphate.

[0033] The preparation method of the high-purity barium metaphosphate of the present invention has the advantages of simple technological process, small equipment investment, economy and environmental protection, and conforms to the concept of green chemistry. It has been proved by practice that the present invention can obta...

Embodiment 1

[0068] Concentrated phosphoric acid (85%, 14.6mol / L, Fe content is 1.2ppm) 3420mL is fixed to 6000mL (solution concentration is 8.32mol / L), the reaction vessel is placed in 80 ℃ constant temperature water bath, pre-charged to the reaction vessel Add 2400mL of phosphoric acid solution (40%), after the temperature of phosphoric acid solution in the reaction vessel rises to 80°C, use a constant flow pump to add the remaining 3600mL of phosphoric acid solution while adding 3000g of high-purity barium carbonate to carry out the synthesis reaction. The added phosphoric acid and barium carbonate The molar ratio was 29.9:15.20, the two were fed simultaneously at a rate of about 120mL:100g, and the stirring was started at 500r / min at the same time. After the feeding was completed, the reaction was continued for 1h, and centrifuged to obtain a crystal wet weight of 4380g, a filtrate of 4320mL, and an acidity of 4.15mol / L.

[0069] After the crystals were dried at 100°C, they were burned ...

Embodiment 2

[0071] Recover 4300ml of the filtrate reacted in Example 1 (phosphoric acid concentration 2.96mol / L, acidity 4.15mol / L), add it as the reaction bottom liquid in the reaction vessel, place the reaction vessel in a constant temperature water bath at 85°C, and wait for the reaction After the temperature of the solution in the container rises to 85°C, use a constant flow pump to add 2070mL of concentrated phosphoric acid (85%, AR) and 3000g of high-purity barium carbonate to carry out the synthesis reaction at the same time. 500r / min, the reaction was continued for 1.5h after feeding, and centrifuged to obtain a crystal wet weight of 5500g, a filtrate of 4600mL, and an acidity of 4.02mol / L.

[0072] After the crystals were dried at 100°C, they were burned in a high-temperature furnace at 580°C for 6 hours. Then wash the burned sample once: the ratio of material to water is 1:2, the washing temperature is 60°C, the washing time is 1h, and after washing with water, dry it at 100°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com