Ti-MWW molecular sieve and preparation method and application thereof

A technology of molecular sieves and titanium-silicon molecular sieves, applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve problems such as suitable hydrophilicity, inability to prepare skeleton titanium, low hydrophilicity of skeleton titanium content, etc. Achieve the effect of suitable hydrophilicity, effective regulation of repairing hydrophilicity, and high content of titanium in the skeleton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

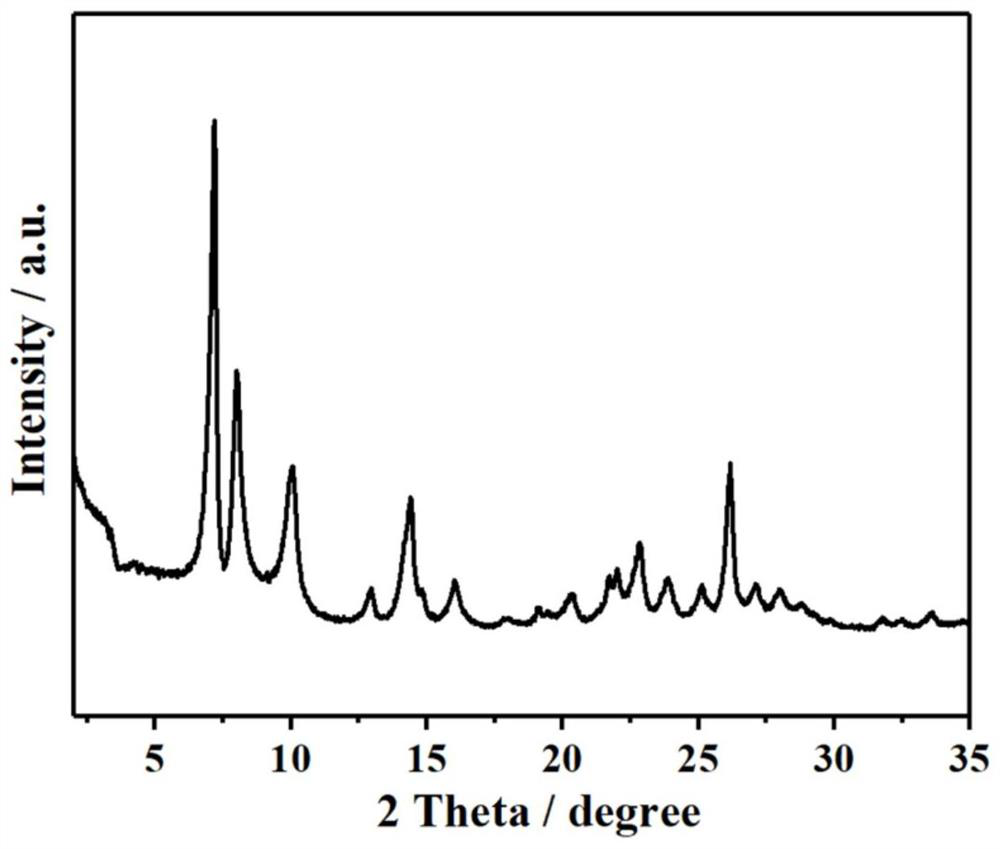

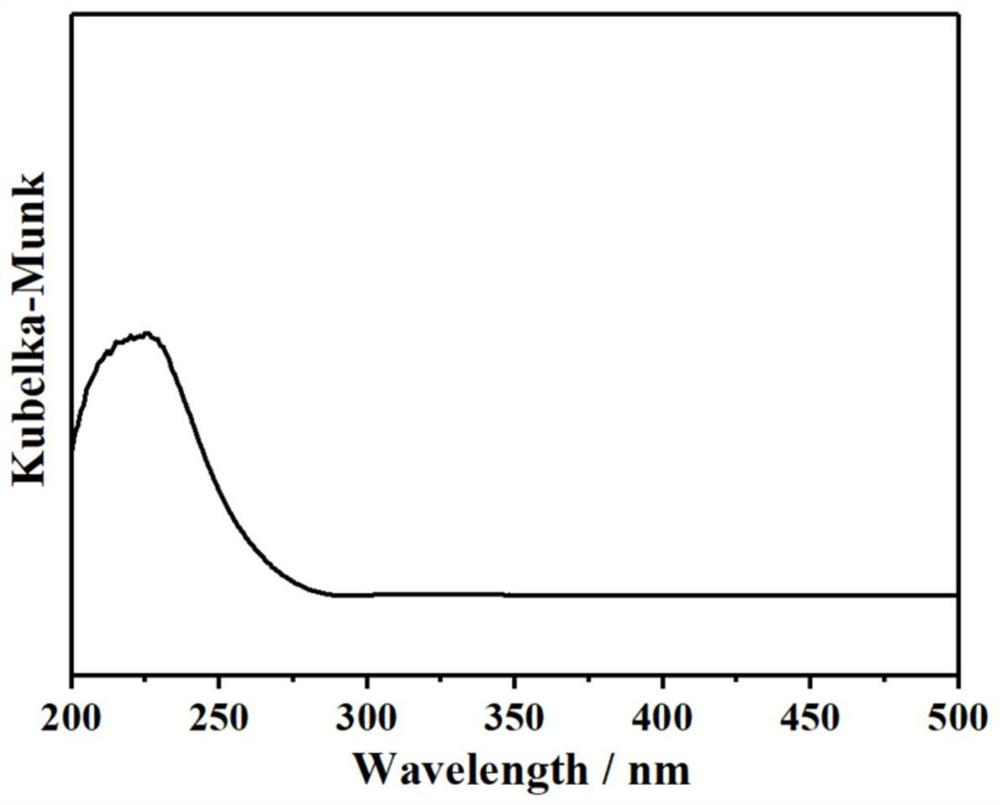

[0045] Molar ratio SiO 2 :B 2 o 3 : piperidine: water 1: 0.6: 1.5: 20. The corresponding amount of water, piperidine, boric acid and 60 grams of fumed silica were evenly mixed to form a gel, and dynamic hydrothermal crystallization was carried out at 50 rpm and 170 °C for 5 days. Centrifuge, wash, and dry at 80°C for 12 hours to obtain a B-MWW molecular sieve precursor. Then mix the B-MWW molecular sieve precursor with 2mol / L nitric acid solution at a mass ratio of 1:20, and then add tetra-n-butyl titanate to make the molar ratio of the B-MWW molecular sieve precursor to 0.06:1. Treat at 80°C for 24 hours to replenish titanium, centrifuge, wash, dry at 80°C for 12 hours, and calcine at 550°C in an air atmosphere for 10 hours to obtain a titanium-silicon molecular sieve with MWW structure. Then mix the MWW structure titanium-silicon molecular sieve with the nitric acid solution with a pH value of 1 at a mass ratio of 1:100, treat it at 160°C for 6 days, centrifuge, wash, dry...

Embodiment 2

[0047] Molar ratio SiO 2 :B 2 o 3 : Hexamethyleneimine: Water is 1: 0.8: 1.8: 50 Mix the corresponding amount of water, hexamethyleneimine, sodium tetraborate and 200 grams of silica sol with a mass fraction of 30% evenly, at 50rpm, Dynamic hydrothermal crystallization at 170°C for 5 days, centrifugation, washing, and drying at 80°C for 12 hours to obtain the B-MWW molecular sieve precursor. Then mix the B-MWW molecular sieve precursor with 2mol / L nitric acid solution at a mass ratio of 1:20, and then add tetra-n-butyl titanate to make the molar ratio of the B-MWW molecular sieve precursor to 0.06:1. Treat at 80°C for 24 hours to replenish titanium, centrifuge, wash, dry at 80°C for 12 hours, and calcine at 550°C in an air atmosphere for 10 hours to obtain a titanium-silicon molecular sieve with MWW structure. Then mix the MWW structure titanium-silicon molecular sieve with the nitric acid solution with a pH value of 1 at a mass ratio of 1:100, treat it at 160°C for 6 days,...

Embodiment 3

[0049] Molar ratio SiO 2 :B 2 o 3 : piperidine: water 1: 0.4: 1.0: 20. The corresponding amount of water, piperidine, boric acid and 60 grams of fumed silica were evenly mixed into a gel, and dynamic hydrothermal crystallization was carried out at 50 rpm and 170 °C for 5 days. Centrifuge, wash, and dry at 80°C for 12 hours to obtain a B-MWW molecular sieve precursor. Then mix the B-MWW molecular sieve precursor with 2mol / L nitric acid solution at a mass ratio of 1:20, and then add tetra-n-butyl titanate to make the molar ratio of the B-MWW molecular sieve precursor to 0.06:1. Treat at 80°C for 24 hours to replenish titanium, centrifuge, wash, dry at 80°C for 12 hours, and calcine at 550°C in an air atmosphere for 10 hours to obtain a titanium-silicon molecular sieve with MWW structure. Then mix the MWW structure titanium-silicon molecular sieve with the nitric acid solution with a pH value of 1 at a mass ratio of 1:100, treat it at 160°C for 6 days, centrifuge, wash, dry at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com