Method for degrading organic wastewater based on cooperation of natural tourmaline and hydrogen peroxide

A hydrogen peroxide and organic wastewater technology, which is applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of incomplete oxidation, high equipment requirements, high cost, etc., and achieve green environmental protection in the degradation process , simplified catalytic process, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A method based on natural tourmaline synergistically degrading organic wastewater with hydrogen peroxide

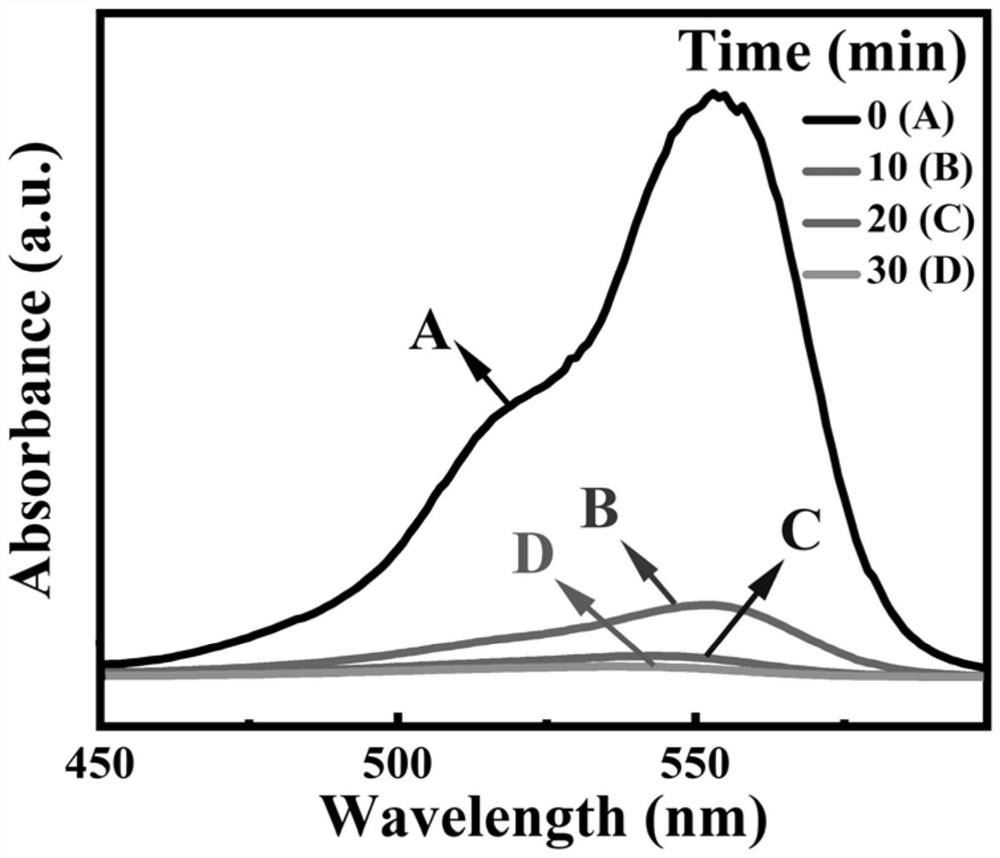

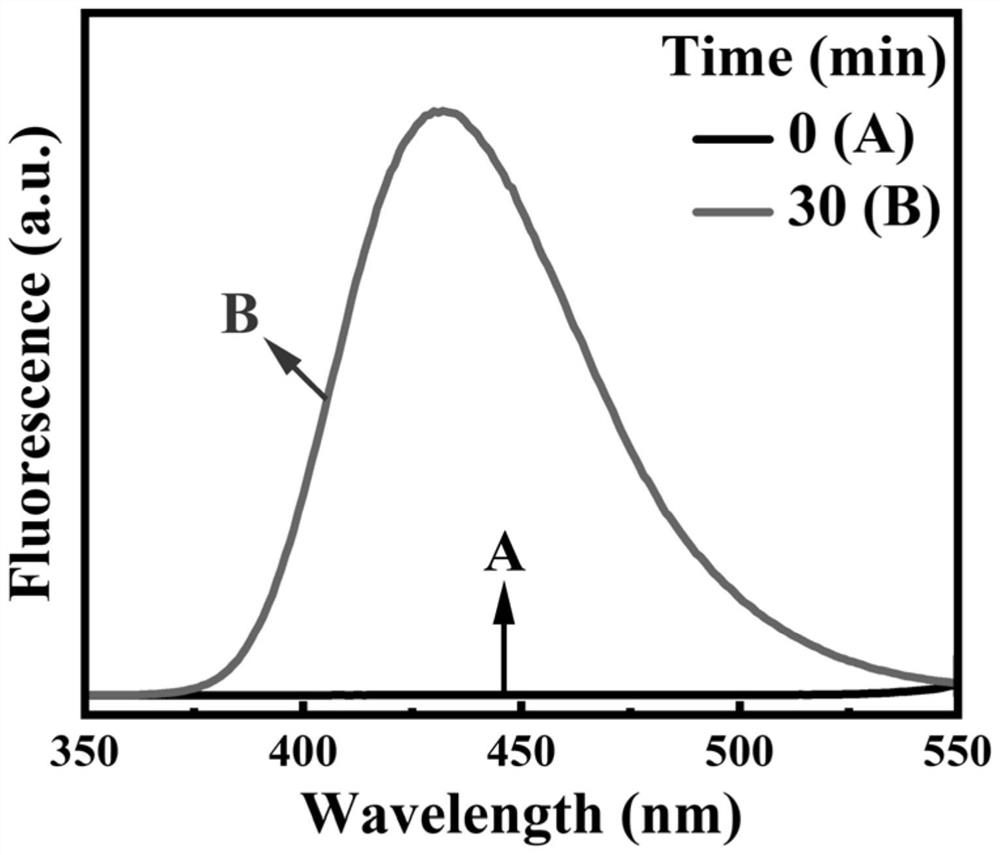

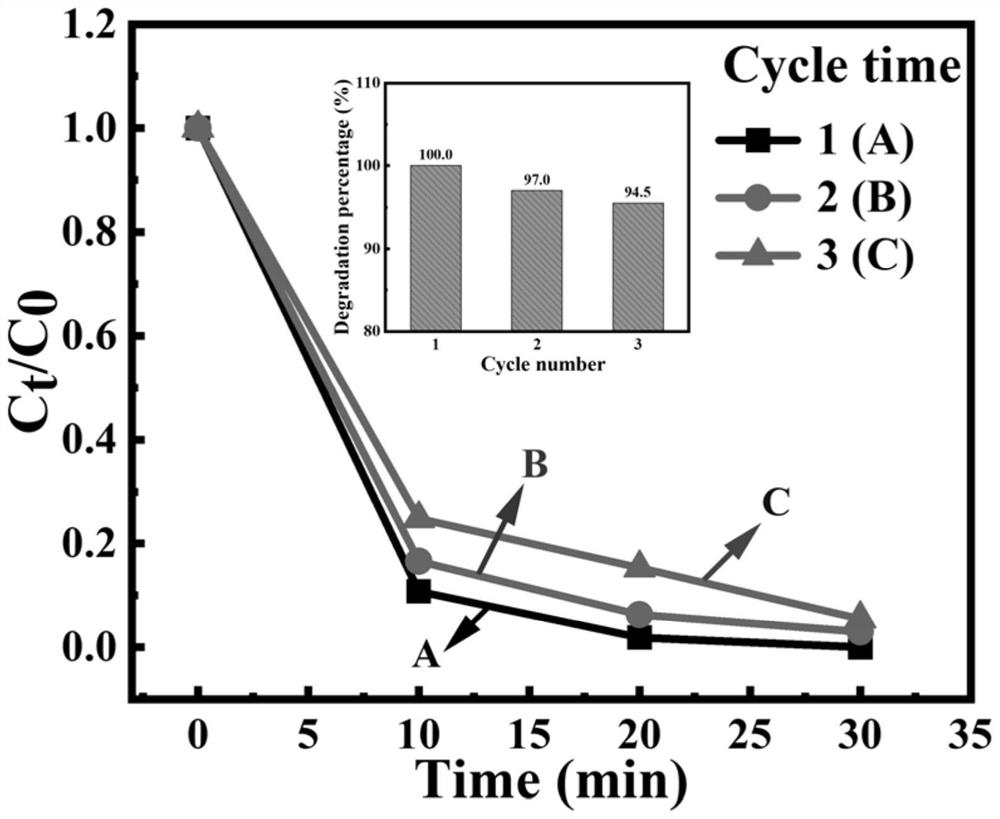

[0029] Prepare 1000mL of rhodamine B aqueous solution with a concentration of 100mg / L, take 100mL of rhodamine B aqueous solution and place it in a 250mL beaker, use hydrogen peroxide and hydrochloric acid to adjust the pH of the solution to 1-4, add 0.6g lithium tourmaline powder, and magnetically stir the reaction For 1 hour, establish the adsorption-desorption equilibrium between lithium tourmaline and rhodamine B solution, add 0.7mL hydrogen peroxide, put it into a water bath and heat it, and set the temperature at 30-80°C. After 30 minutes, the degradation efficiency of rhodamine B can reach 99.9%. figure 1 Shown; Hydroxyl radical trapping fluorescence spectrum is shown in figure 2 Shown; the cycle efficiency graph of lithium tourmaline is shown in image 3 shown. It can be seen that the lithium tourmaline powder of the present invention can b...

Embodiment 2

[0030] Embodiment 2 A method based on natural tourmaline synergistically degrading organic wastewater with hydrogen peroxide

[0031] Prepare 1000mL of rhodamine B aqueous solution with a concentration of 100mg / L, take 100mL of rhodamine B aqueous solution and place it in a 250mL beaker, use hydrogen peroxide and sulfuric acid to adjust the pH of the solution to 1-4, add 0.6g lithium tourmaline powder, and magnetically stir the reaction For 1 hour, establish the adsorption-desorption equilibrium between lithium tourmaline and rhodamine B solution, add 0.7mL hydrogen peroxide, put it into a water bath and heat it, and set the temperature at 30-80°C. After 30 minutes, the degradation efficiency of rhodamine B can reach 99.9%.

Embodiment 3

[0032] Embodiment 3 A method based on natural tourmaline synergistically degrading organic wastewater with hydrogen peroxide

[0033] Prepare 1000mL of ethyl violet and methyl orange mixed aqueous solution with a concentration of 100mg / L (ethyl violet: methyl orange mass ratio is 1:1), take 100mL ethyl violet and methyl orange mixed aqueous solution and place it in a 250mL beaker, Use hydrogen peroxide and hydrochloric acid to adjust the pH of the solution to 1-4, add 0.6g lithium tourmaline powder, and stir the reaction for 1 hour to establish the adsorption-desorption equilibrium between lithium tourmaline, ethyl violet and methyl orange mixed solution, add Put 0.7mL of hydrogen peroxide into the water bath and heat, set the temperature at 30-80°C. After 30 minutes, the degradation efficiency of the mixed solution of ethyl violet and methyl orange can reach 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com