Mineral-based soil conditioner for improving coastal saline soil and preparation method thereof

A technology of soil conditioner and sea salt, which is applied in the direction of soil conditioning materials, chemical instruments and methods, applications, etc., can solve the problems that the effect needs to be further improved, reduce soil salinity, and is difficult to configure, so as to achieve low production costs and improve rice production. Yield, good adsorption capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

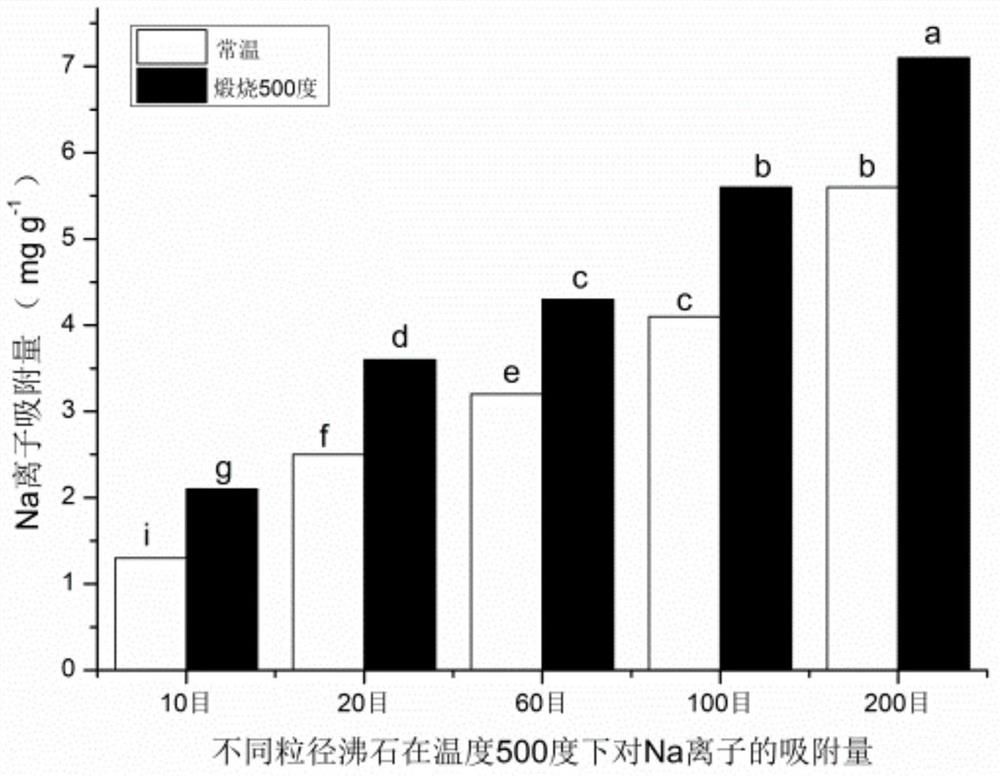

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a mineral-based soil conditioner for seaside saline soil improvement, including 400 parts by mass of modified zeolite, 150 parts of urea, 150 parts of superphosphate, 100 parts of water-retaining agent, 80 parts of parts of ammonium sulfate, 50 parts of ferrous sulfate and 100 parts of bentonite.

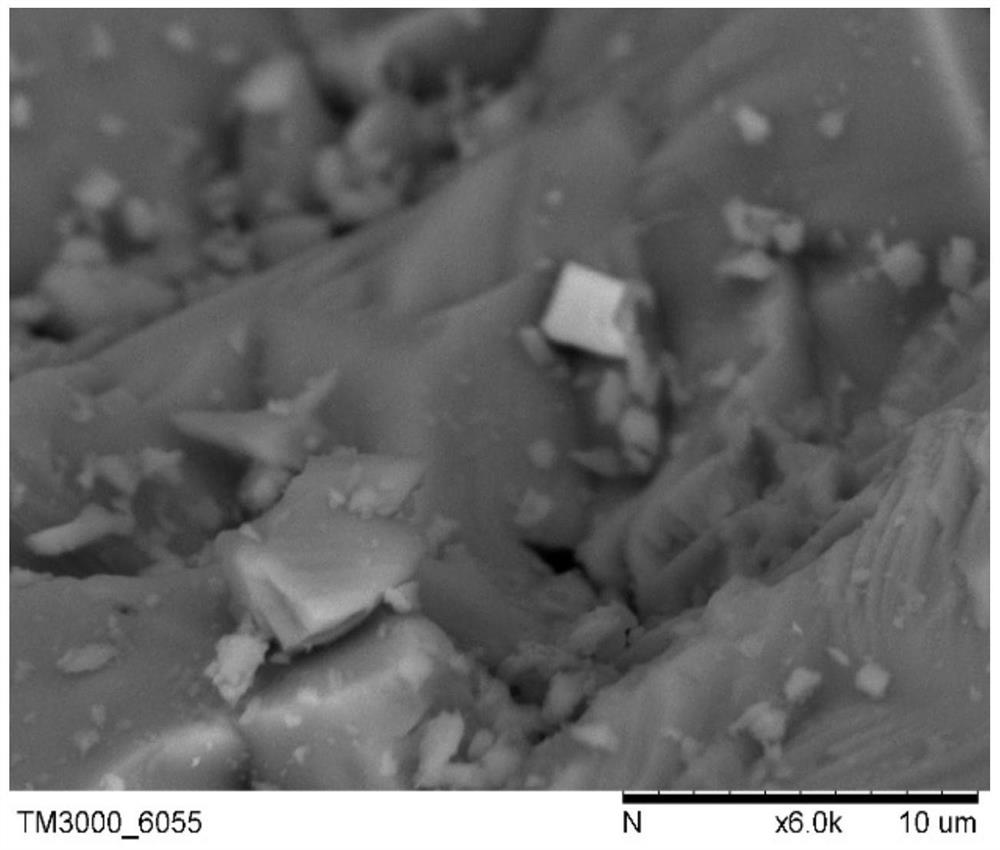

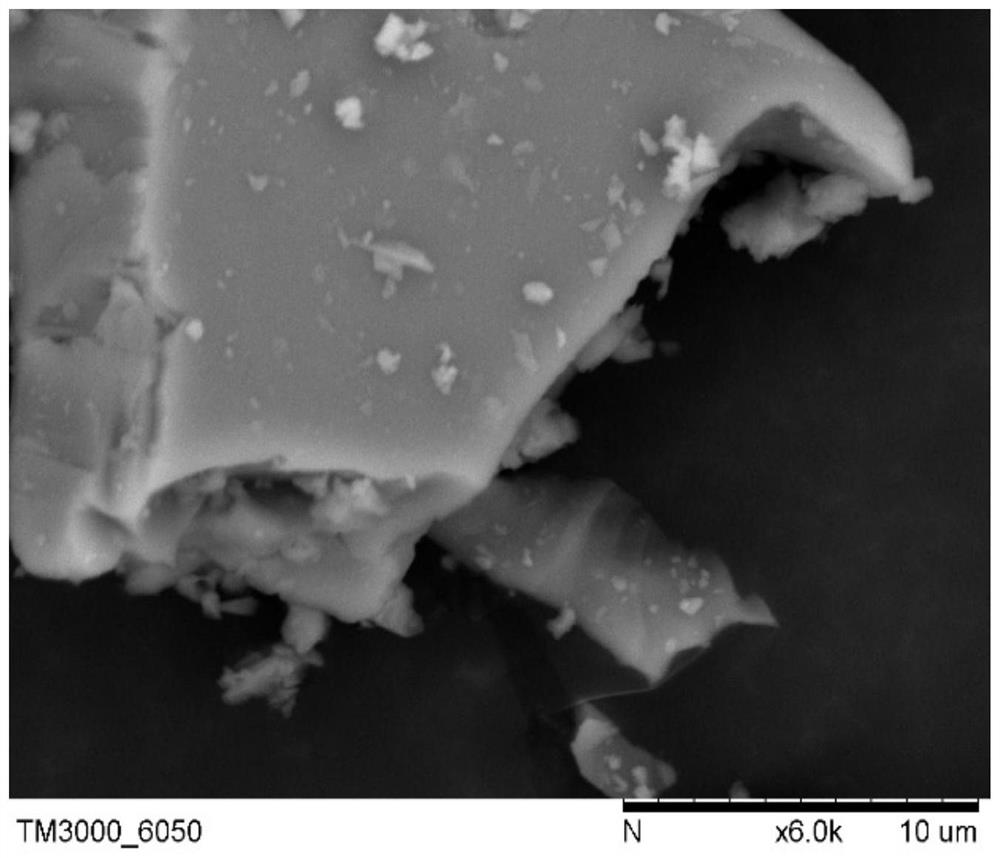

[0034] Modified zeolites are modified by the following steps:

[0035] Step 1: Take zeolite, modifier and solvent, dissolve the modifier into the solvent, add zeolite, and heat to reflux for 30 minutes;

[0036] Step 2: After naturally cooling to room temperature, filter to separate the solid and liquid phases;

[0037] Step 3: Calcining the solid phase obtained in Step 2 at 550° C. for 40 min to obtain a modified zeolite.

[0038] Wherein, the component of zeolite and modifying agent comprises the zeolite that mass parts are respectively 600 parts, the aluminum sulfate of 60 parts, the magnesium sulfate of 50 parts and the phosphoric acid of 100 pa...

Embodiment 2

[0042] This embodiment provides a mineral-based soil conditioner for improvement of coastal saline soil, including 600 parts by mass of modified zeolite, 100 parts of urea, 100 parts of superphosphate, 60 parts of water-retaining agent, 30 parts 15 parts of ammonium sulfate, 15 parts of ferrous sulfate and 50 parts of bentonite.

[0043] Modified zeolites are modified by the following steps:

[0044] Step 1: Take zeolite, modifier and solvent, dissolve the modifier into the solvent, add zeolite, and heat to reflux for 60 minutes;

[0045] Step 2: After naturally cooling to room temperature, filter to separate the solid and liquid phases;

[0046] Step 3: Calcining the solid phase obtained in Step 2 at 450° C. for 20 minutes to obtain a modified zeolite.

[0047] Wherein, the component of zeolite and modifying agent comprises the zeolite that mass parts are respectively 400 parts, the aluminum sulfate of 80 parts, the magnesium sulfate of 150 parts and the phosphoric acid of ...

Embodiment 3

[0049] This embodiment provides a mineral-based soil conditioner for seaside saline soil improvement, including 500 parts by mass of modified zeolite, 125 parts of urea, 125 parts of superphosphate, 80 parts of water retaining agent, 55 parts 30 parts of ammonium sulfate, 30 parts of ferrous sulfate and 75 parts of bentonite.

[0050] Modified zeolites are modified by the following steps:

[0051] Step 1: Take zeolite, modifier and solvent, dissolve the modifier into the solvent, add zeolite, and heat to reflux for 45 minutes;

[0052] Step 2: After naturally cooling to room temperature, filter to separate the solid and liquid phases;

[0053] Step 3: Calcining the solid phase obtained in Step 2 at 500° C. for 30 min to obtain a modified zeolite.

[0054] Wherein, the component of zeolite and modifying agent comprises the zeolite that mass parts are respectively 500 parts, the aluminum sulfate of 70 parts, the magnesium sulfate of 100 parts and the phosphoric acid of 200 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com