Waterborne two-component epoxy anticorrosive coating and preparation method thereof

An epoxy anti-corrosion coating, two-component technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of decreased storage stability of coatings, health hazards of operators, and reduced coating compactness. Achieve the effect of high density, excellent corrosion resistance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

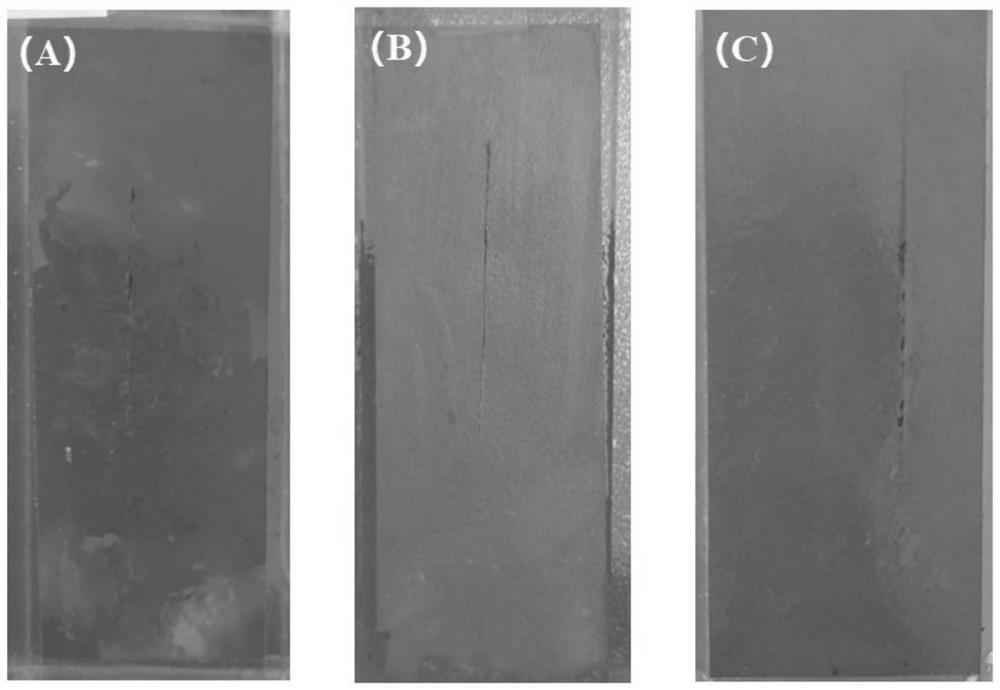

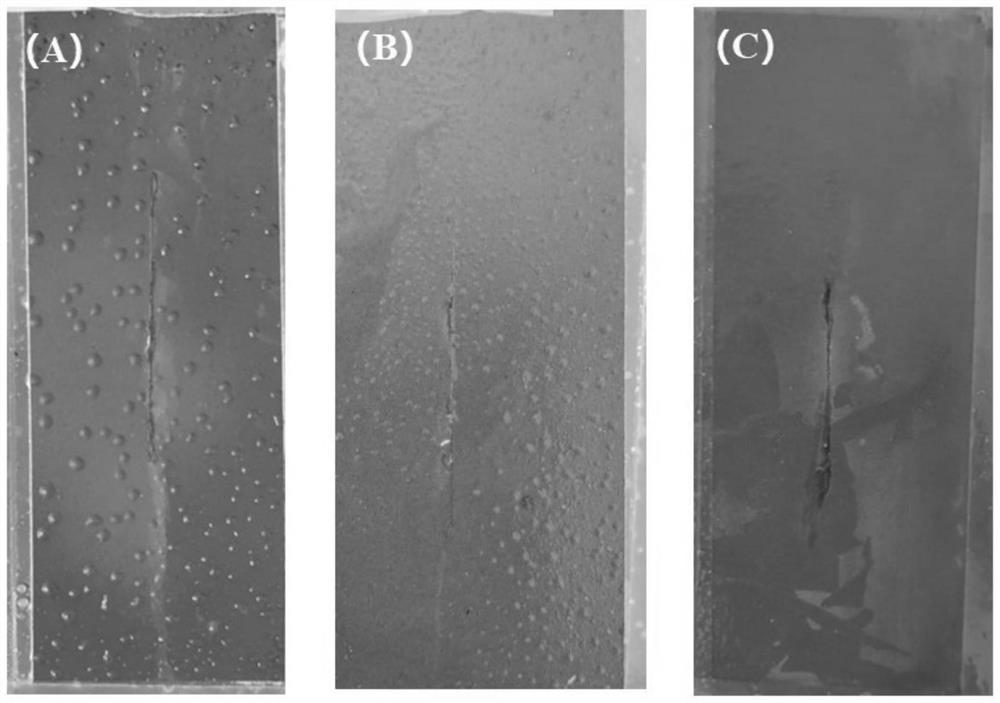

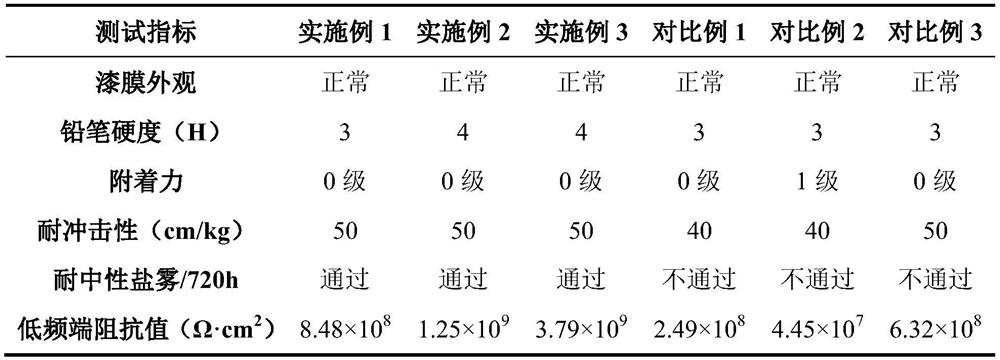

Embodiment 1

[0058] A waterborne two-component epoxy anti-corrosion coating consisting of A component and B component:

[0059] Component A consists of the following raw materials in parts by mass:

[0060] Zinc powder (spherical, particle size 18μm~23μm): 25.73 parts;

[0061] Propylene glycol methyl ether (film-forming aid): 9.62 parts;

[0062] Propylene glycol phenyl ether (film-forming aid): 2.40 parts;

[0063] ADDITOL-VXW 6208 / 60 (dispersant): 0.48 parts;

[0064] MT 6650 (thickener): 0.64 parts;

[0065] Fumed silica (anti-settling agent): 0.80 parts;

[0066] EPIKURE8538-Y-68 (curing agent): 8.50 parts;

[0067] Component B consists of the following raw materials in parts by mass:

[0068] Epikote6520-WH-53A (bisphenol A type epoxy resin, epoxy equivalent 500g / eq~600g / eq): 36.07 parts;

[0069] Graphene oxide slurry: 1.02 parts;

[0070] ASCOTRAN-H14 (anti-flash rust agent): 0.26 parts;

[0071] Deionized water: 14.43 parts.

[0072] The preparation method of above-mention...

Embodiment 2

[0078] A waterborne two-component epoxy anti-corrosion coating consisting of A component and B component:

[0079] Component A consists of the following raw materials in parts by mass:

[0080] Zinc powder (spherical, particle size 18μm~23μm): 25.21 parts;

[0081] Propylene glycol methyl ether (film-forming aid): 9.42 parts;

[0082] Propylene glycol phenyl ether (film-forming aid): 2.36 parts;

[0083] ADDITOL-VXW 6208 / 60 (dispersant): 0.47 parts;

[0084] MT 6650 (thickener): 0.63 parts;

[0085] Fumed silica (anti-settling agent): 0.79 parts;

[0086] EPIKURE8538-Y-68 (curing agent): 8.32 parts;

[0087] Component B consists of the following raw materials in parts by mass:

[0088] Epikote6520-WH-53A (bisphenol A type epoxy resin, epoxy equivalent 500g / eq~600g / eq): 35.34 parts;

[0089] Graphene oxide slurry: 3.03 parts;

[0090] ASCOTRAN-H14 (anti-flash rust agent): 0.16 parts;

[0091] Deionized water: 14.14 parts.

[0092] The preparation method of above-menti...

Embodiment 3

[0098] A waterborne two-component epoxy anti-corrosion coating consisting of A component and B component:

[0099] Component A consists of the following raw materials in parts by mass:

[0100] Zinc powder (spherical, particle size 18μm~23μm): 33.34 parts;

[0101] Propylene glycol methyl ether (film-forming aid): 8.31 parts;

[0102] Propylene glycol phenyl ether (film-forming aid): 2.08 parts;

[0103] ADDITOL-VXW 6208 / 60 (dispersant): 0.42 parts;

[0104] MT 6650 (thickener): 0.55 parts;

[0105] Fumed silica (anti-settling agent): 0.69 parts;

[0106] EPIKURE8538-Y-68 (curing agent): 7.34 parts;

[0107] Component B consists of the following raw materials in parts by mass:

[0108] Epikote6520-WH-53A (bisphenol A type epoxy resin, epoxy equivalent 500g / eq~600g / eq): 31.16 parts;

[0109] Graphene oxide slurry: 3.32 parts;

[0110] ASCOTRAN-H14 (anti-flash rust agent): 0.28 parts;

[0111] Deionized water: 12.46 parts.

[0112] The preparation method of above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com