Metasurface-based optical fiber humidity sensor and manufacturing method thereof,

A technology of humidity sensor and fiber optic sensor, which is applied in instruments, scientific instruments, and material analysis through optical means, and can solve problems such as small effective sensing area, limited number of effective resonance peaks, and large effective sensing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

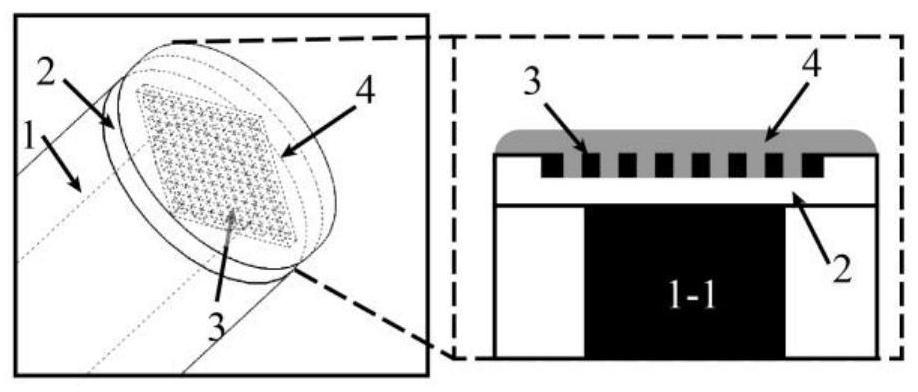

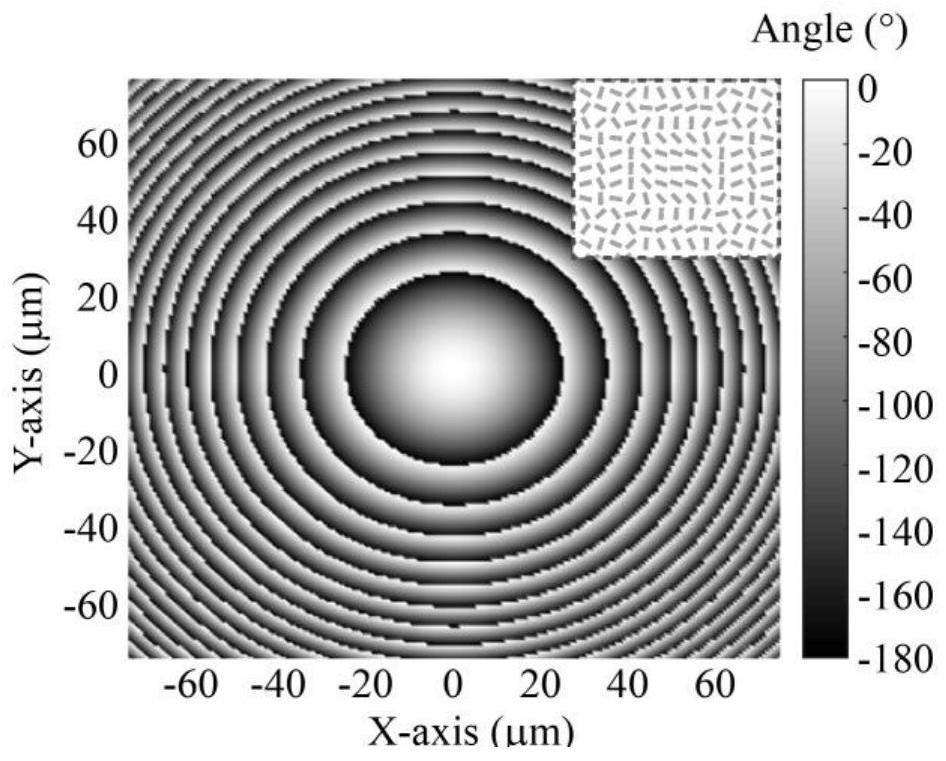

[0035] The present invention will be described in detail below with reference to the drawings and embodiments. At the same time, the technical problems and beneficial effects solved by the technical solution of the present invention are also described. It should be pointed out that the described embodiments are only intended to facilitate the understanding of the present invention, and have no limiting effect on it.

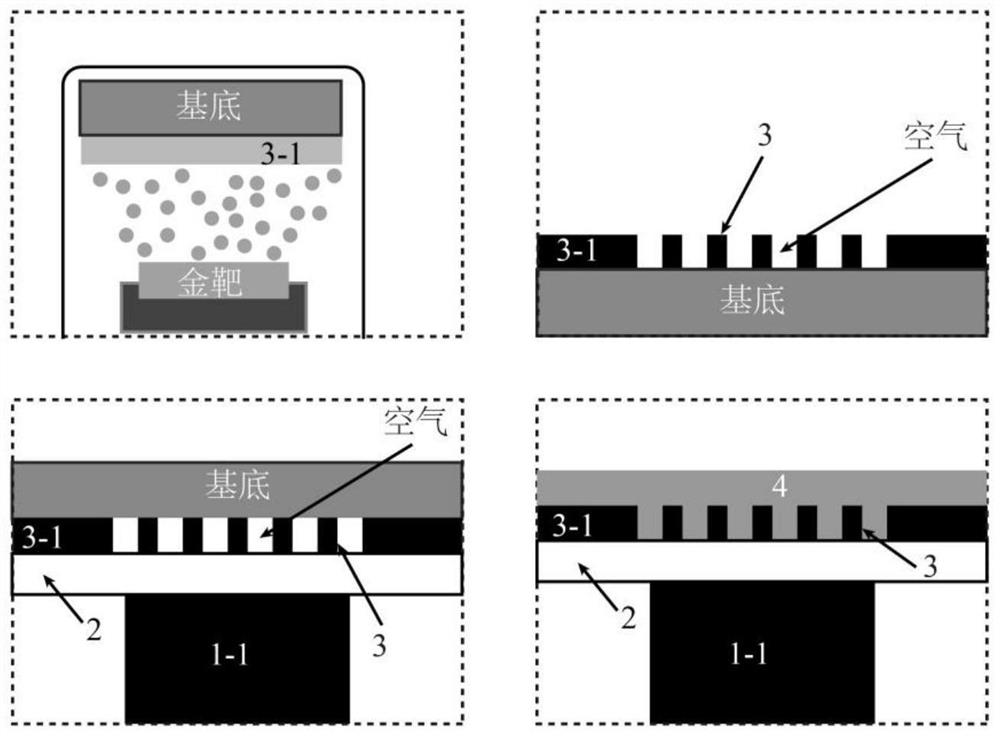

[0036] Such as figure 2 As shown, the preparation method of the optical fiber humidity sensor based on the fiber end metasurface disclosed in this embodiment, the specific implementation method is as follows:

[0037] Step 1: Clean the substrate first, and use a coating machine to prepare a metal film 3-1 on one side of the substrate. Usually, thermal resistance evaporation coating, electron beam evaporation coating, ion beam evaporation coating, magnetic sputtering coating, etc. can be used.

[0038] In order to ensure easy peeling between the metal film 3-1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com