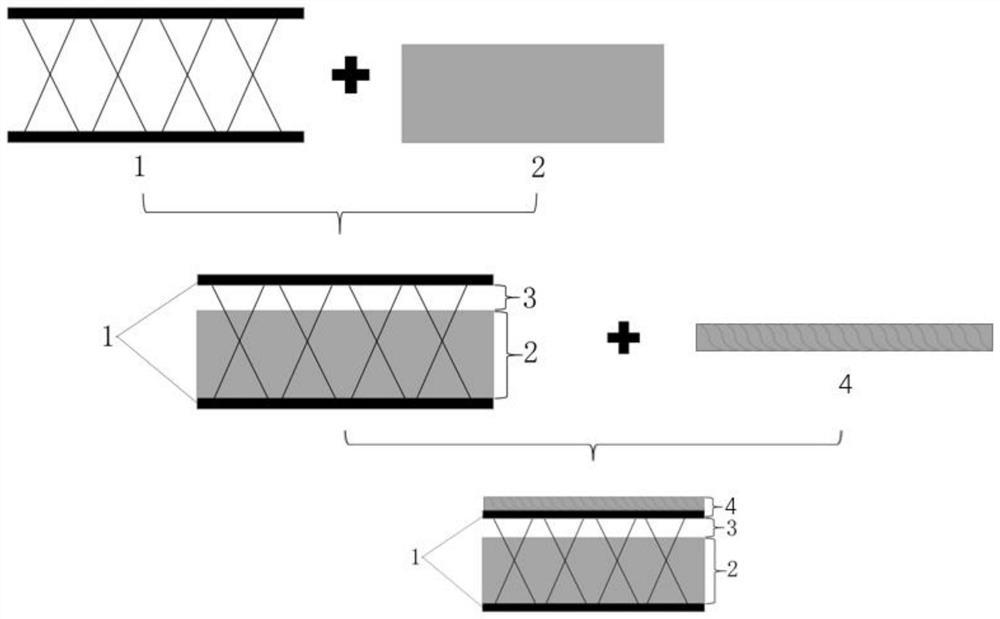

Medical composite self-pumping dressing with multi-layer structure as well as preparation method and application of medical composite self-pumping dressing

A multi-layer structure, self-pumping technology, used in dressings, pharmaceutical formulations, non-adhesive dressings, etc., can solve the problems of complicated healing process, achieve good application prospects, improve liquid absorption capacity, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a multilayered medical composite self-pump dressing, comprising the following steps:

[0040] Step 1: Dissolve 2g of sodium alginate in 100ml of distilled water to prepare a 2% sodium alginate aqueous solution;

[0041] Step 2: Stir magnetically for 3 hours to form a homogeneous solution;

[0042] Step 3: Stand still for 24 hours under the conditions of relative humidity of 60% and temperature of 25°C;

[0043] Step 4: Use the double-needle bed Raschel warp knitting machine to knit the warp-knitted three-dimensional spacer fabric whose surface layer is knitting chain + weft insertion; the three-dimensional spacer fabric adopts double-needle bed Raschel warp knitting with a total of 6 bars from GB1 to GB6 Machine weaving, the yarns on GB2 and GB5 are hydrophobic fiber multifilaments, the yarns on GB1 and GB6 are carbon fiber tows, and the yarns on GB3 and GB4 are hydrophobic fiber monofilaments with a diameter of 0.2mm; GB1 and GB2 Knit the top l...

Embodiment 2

[0050] A method for preparing a multilayered medical composite self-pump dressing, comprising the following steps:

[0051] Step 1: Dissolve 5g of sodium alginate in distilled water to prepare an aqueous solution of sodium alginate with a mass fraction of 5%;

[0052] Step 2: Stir magnetically for 6 hours to form a homogeneous solution;

[0053] Step 3: Stand still for 20 hours under the conditions of relative humidity of 65% and temperature of 28°C;

[0054] Step 4: Use the double-needle bed Raschel warp knitting machine to knit the warp-knitted three-dimensional spacer fabric whose surface layer is knitting chain + weft insertion; the three-dimensional spacer fabric adopts double-needle bed Raschel warp knitting with a total of 6 bars from GB1 to GB6 Machine weaving, the yarns on GB2 and GB5 are hydrophobic fiber multifilaments, the yarns on GB1 and GB6 are carbon fiber tows, and the ones on GB3 and GB4 are hydrophobic fiber monofilaments; The front needle bed weaves the t...

Embodiment 3

[0061] A method for preparing a multilayered medical composite self-pump dressing, comprising the following steps:

[0062] Step 1: Dissolve 10 g of sodium alginate in distilled water to prepare an aqueous solution of sodium alginate with a mass fraction of 10%;

[0063] Step 2: Stir magnetically for 5 hours to form a homogeneous solution;

[0064] Step 3: Stand still for 20 hours under the conditions of relative humidity of 65% and temperature of 22°C;

[0065] Step 4: Use the double-needle bed Raschel warp knitting machine to knit the warp-knitted three-dimensional spacer fabric whose surface layer is knitting chain + weft insertion; the three-dimensional spacer fabric adopts double-needle bed Raschel warp knitting with a total of 6 bars from GB1 to GB6 Machine weaving, the yarns on GB2 and GB5 are hydrophobic fiber multifilaments, the yarns on GB1 and GB6 are carbon fiber tows, and the yarns on GB3 and GB4 are hydrophobic fiber monofilaments with a diameter of 0.2mm; GB1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com