Method for rapidly dissolving p-hydroxyacetophenone at low temperature

A fast technology for p-hydroxyacetophenone, applied in the field of chemical technology, can solve the problems of complex operation process, influence of subsequent processes, insufficient dissolution, etc., and achieve the effects of improving dissolution efficiency, avoiding high temperature volatilization, and shortening dissolution time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

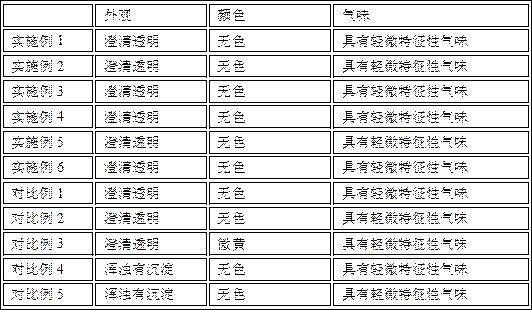

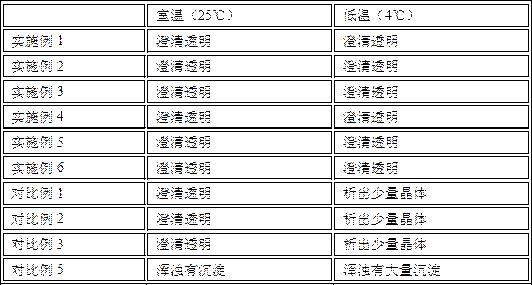

Examples

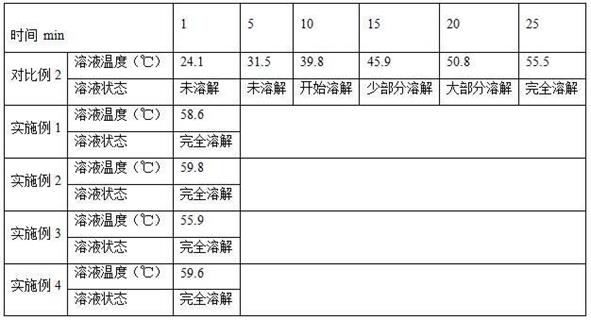

Embodiment 1

[0028] The present embodiment provides a method for rapidly dissolving p-hydroxyacetophenone at low temperature, which includes:

[0029] S1. Mix 1 part of dipropylene glycol at 25°C with 0.8 part of deionized water at 85°C and stir evenly to obtain an aqueous solution of dipropylene glycol, whose temperature is measured to be 58.6°C.

[0030] S2. Immediately add 0.4 parts of p-hydroxyacetophenone to the above-mentioned dipropylene glycol aqueous solution, and stir rapidly to dissolve for 60 s.

Embodiment 2

[0032] The present embodiment provides a method for rapidly dissolving p-hydroxyacetophenone at low temperature, which includes:

[0033] S1. Mix 1 part of pentanediol at 30°C with 0.8 part of deionized water at 80°C and stir evenly to obtain an aqueous solution of pentanediol, whose temperature is measured to be 59.8°C.

[0034] S2. Immediately add 0.4 parts of p-hydroxyacetophenone into the above-mentioned aqueous solution of pentylene glycol, and stir rapidly to dissolve for 45 s.

Embodiment 3

[0036] The present embodiment provides a method for rapidly dissolving p-hydroxyacetophenone at low temperature, which includes:

[0037] S1. Mix 1 part of butanediol at 20°C with 0.6 part of deionized water at 80°C and stir evenly to obtain an aqueous solution of butanediol, whose temperature is measured to be 55.9°C.

[0038] S2. Immediately add 0.4 parts of p-hydroxyacetophenone to the above-mentioned butanediol aqueous solution, and stir rapidly to dissolve for 50 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com