Polyimide slurry and polyimide film

A technology of polyimide film and polyimide, which is applied in the field of electronic packaging, can solve the problems of low content, achieve good processability, reduce production energy consumption, and facilitate long-term storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of microcapsule cyclizing agent

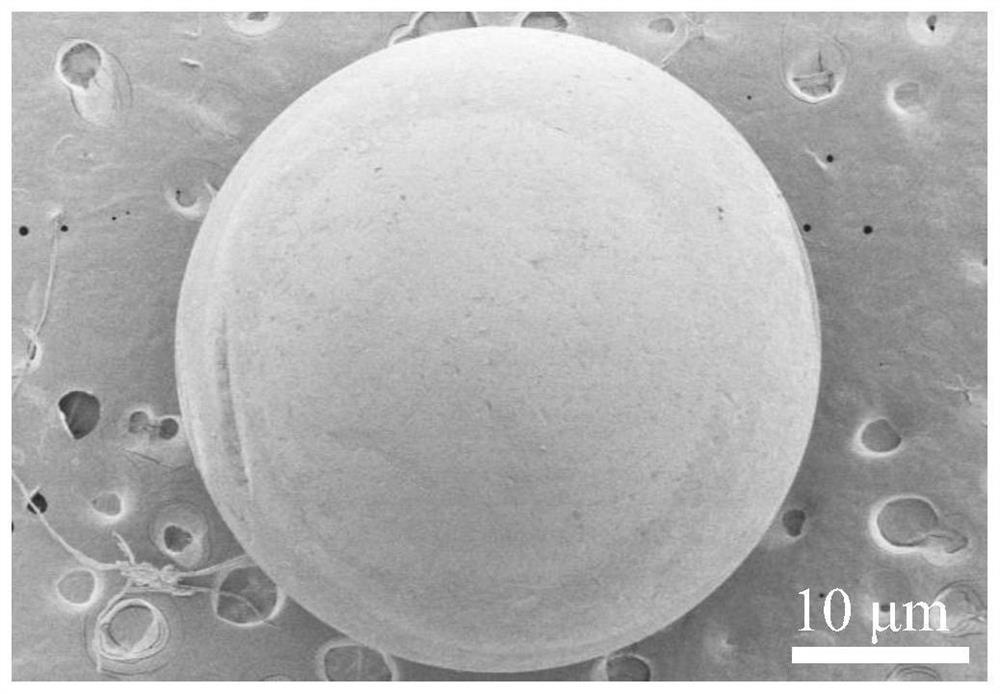

[0030] The total weight of raw materials is 1Kg, 30 parts by weight of methyl silicone oil is heated to 50°C, and 1 part by weight of paraffin, 30 parts by weight of chemical cyclizing agent and 0.5 part by weight of polyoxyethyl ether are added at a rate of 1 mL / min, wherein the chemical The cyclizing agent is composed of acetic anhydride and triethylamine, the molar ratio of which is 1:1. After stirring and mixing evenly, cooling, suction filtration and crushing, a capsule chemical cyclizing agent with a size of 30-50 μm is obtained, such as figure 1 shown.

[0031] (2) Preparation of polyimide slurry

[0032] Dissolve 14.01 g of 4,4’-diaminodiphenyl ether in 161.70 mL of N-methylpyrrolidone, add 15.26 g of pyromellitic anhydride, and react for 12 hours to obtain a transparent polyamic acid solution (mass fraction: 15 wt%). Add 15.00 g of capsule-shaped cyclizing agent, mix evenly after stirring, and obtain the polyi...

Embodiment 2

[0037] (1) Preparation of microcapsule cyclizing agent

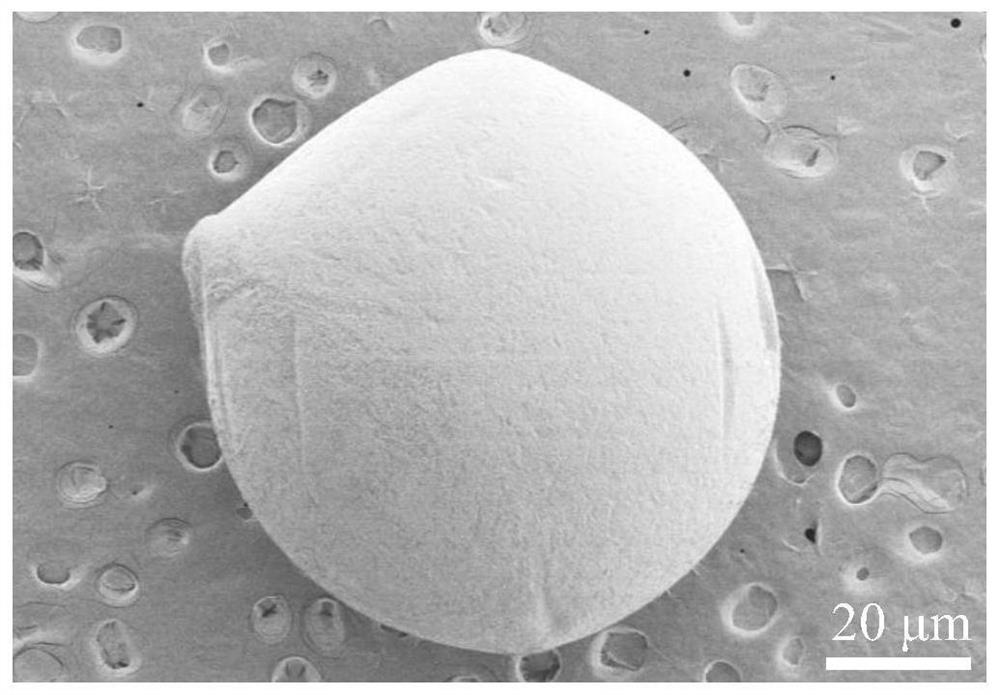

[0038] The total weight of raw materials is 1Kg, 30 parts by weight of methyl silicone oil is heated to 50 ° C, and 15 parts by weight of paraffin, 30 parts by weight of chemical cyclizing agent and 0.5 part by weight of polyoxyethyl ether are added at a rate of 5 mL / min, wherein the chemical cyclic The cyclizing agent is composed of acetic anhydride and triethylamine, the molar ratio of which is 1:1. After stirring and mixing evenly, cooling, suction filtration and crushing, a capsule chemical cyclizing agent with a size of 80-120 μm is obtained, such as figure 2 shown.

[0039] (2) Preparation of polyimide slurry

[0040] Dissolve 14.01 g of 4,4’-diaminodiphenyl ether in 161.70 mL of N-methylpyrrolidone, add 15.26 g of pyromellitic anhydride, and react for 12 hours to obtain a transparent polyamic acid solution (mass fraction: 15 wt%). Add 22.00 g of capsule-shaped cyclizing agent, mix evenly after stirring, and obt...

Embodiment 3

[0045] (1) Preparation of microcapsule cyclizing agent

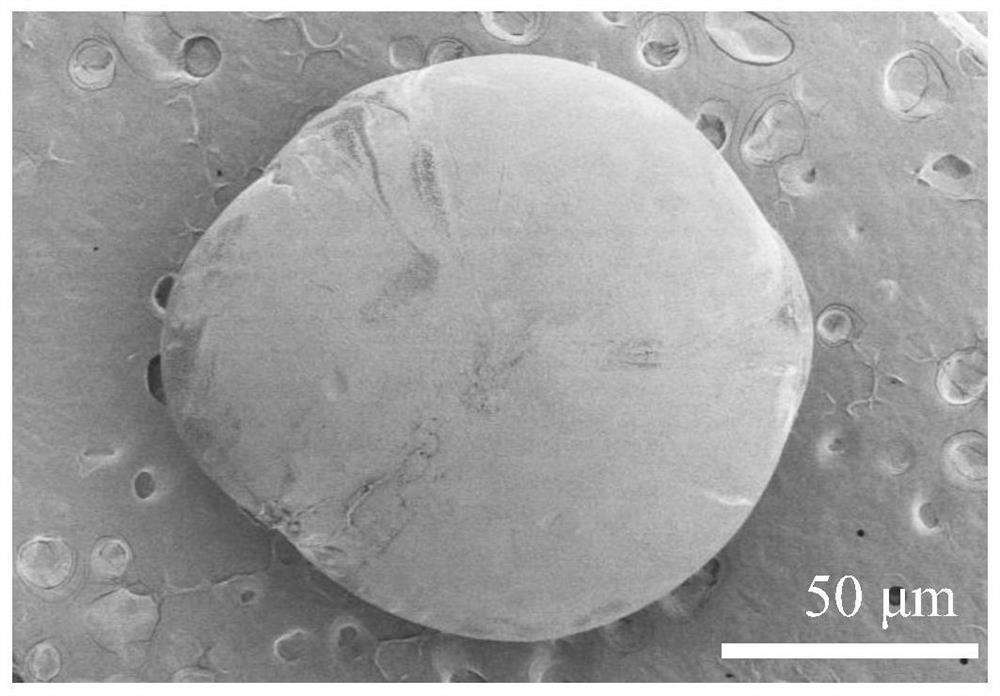

[0046]The total weight of raw materials is 1Kg, 30 parts by weight of methyl silicone oil is heated to 50 ° C, and 15 parts by weight of paraffin, 45 parts by weight of chemical cyclizing agent and 0.5 part by weight of polyoxyethyl ether are added at a rate of 1 mL / min, wherein the chemical cyclic The cyclizing agent is composed of acetic anhydride and isoquinoline with a molar ratio of 1:1. After stirring and mixing evenly, cooling, suction filtration and crushing, a capsule-shaped chemical cyclizing agent with a size of 100-150 μm is obtained, such as image 3 shown.

[0047] (2) Preparation of polyimide slurry

[0048] Dissolve 14.01 g of 4,4'-diaminodiphenyl ether in 161.70 mL of N-methylpyrrolidone, add 20.58 g of 3,3',4,4'-biphenyltetracarboxylic dianhydride, and react for 12 hours to obtain a transparent polyamide Acid solution (mass fraction 15wt%). Add 20 g of capsule-shaped cyclizing agent, mix evenly after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com