A kind of white and polysaccharide-containing traditional Chinese medicine toothpaste and preparation method thereof

A technology of traditional Chinese medicine toothpaste and polysaccharide, applied in the field of daily chemistry, can solve the problems of unreasonable extraction method of traditional Chinese medicine composition, undisclosed specific dosage of 6 traditional Chinese medicines, complex composition of extract components, etc. The effect of healing, effective hemostasis wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

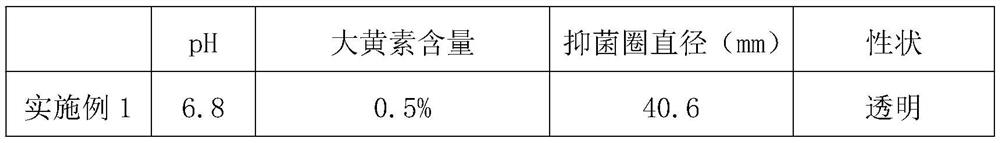

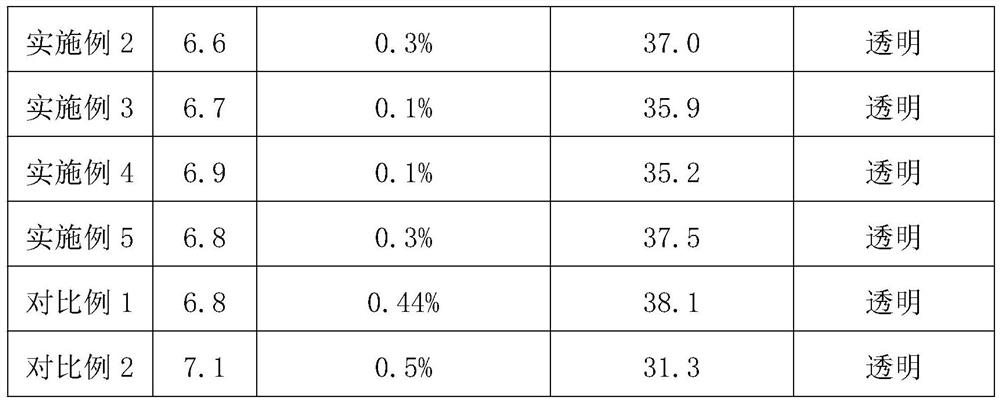

Examples

Embodiment 1

[0040] Baiji polysaccharide 2%, emodin 0.5%, glycerin 20%, sorbitol liquid 30%, saccharin sodium 0.3%, carboxymethyl cellulose sodium 1.5%, friction silicon dioxide 25%, thickening silicon dioxide 10% %, sodium lauryl sulfate 2%, menthol 0.6%, sodium benzoate 0.5%, deionized water 7.6%, all are percentages by weight.

[0041] Preparation:

[0042] (1) 2 parts by weight of white polysaccharides, 0.5 parts by weight of emodin, 0.3 parts by weight of sodium saccharin, 30 parts by weight of sorbitol liquid, 20 parts by weight of glycerin, and 0.5 parts by weight of sodium benzoate are fully dissolved with 7.6 parts by weight of deionized water, Mix evenly to obtain liquid material A;

[0043] (2) 1.5 parts by weight of sodium carboxymethyl cellulose, 25 parts by weight of friction silicon dioxide, 10 parts by weight of thickening silicon dioxide, and 2 parts by weight of sodium lauryl sulfate were uniformly mixed to obtain powder B;

[0044] (3) Add powder B to liquid material A...

Embodiment 2

[0047] Baiji polysaccharide 3%, emodin 0.3%, glycerin 15%, sorbitol solution 45%, saccharin sodium 0.3%, carboxymethyl cellulose sodium 1%, friction silicon dioxide 15%, thickening silicon dioxide 5 %, sodium lauryl sulfate 5%, menthol 1%, sodium benzoate 0.3%, deionized water 9.1%, all are percentages by weight.

[0048] Preparation:

[0049] (1) 3 parts by weight of white polysaccharides, 0.3 parts by weight of emodin, 0.3 parts by weight of sodium saccharin, 45 parts by weight of sorbitol liquid, 15 parts by weight of glycerin, and 0.3 parts by weight of sodium benzoate are fully dissolved with 9.1 parts by weight of deionized water, Mix evenly to obtain liquid material A;

[0050] (2) 1 part by weight of sodium carboxymethyl cellulose, 15 parts by weight of friction silicon dioxide, 5 parts by weight of thickening silicon dioxide, and 5 parts by weight of sodium lauryl sulfate were uniformly mixed to obtain powder B;

[0051] (3) Add powder B to liquid material A, adjust...

Embodiment 3

[0054] Baiji polysaccharide 1%, emodin 0.1%, glycerin 10%, sorbitol solution 50%, saccharin sodium 0.5%, carboxymethyl cellulose sodium 5%, friction silicon dioxide 18%, thickening silicon dioxide 8 %, sodium lauryl sulfate 4%, menthol 0.8%, sodium benzoate 0.1%, deionized water 2.5%, all are percentages by weight.

[0055] Preparation:

[0056] (1) Compounding Baiji polysaccharide and emodin (1 weight part Baiji polysaccharide, 0.1 weight part emodin), 0.5 weight part sodium saccharin, 50 weight part sorbitol liquid, 10 weight part glycerin, 0.1 weight part benzene Sodium formate was fully dissolved with 2.5 parts by weight of deionized water, and mixed uniformly to obtain liquid material A;

[0057] (2) 5 parts by weight of sodium carboxymethylcellulose, 18 parts by weight of friction silicon dioxide, 8 parts by weight of thickening silicon dioxide, and 4 parts by weight of sodium lauryl sulfate were uniformly mixed to obtain powder B;

[0058] (3) Add powder B to liquid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com