Galvanizing corrosion inhibitor in mixed acid medium

A corrosion inhibitor and medium technology, applied in the field of equipment cleaning and protection, can solve the problems of reducing the heat exchange effect of equipment, wasting water and electricity resources, etc., and achieve the effect of low cost, simple manufacturing process and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

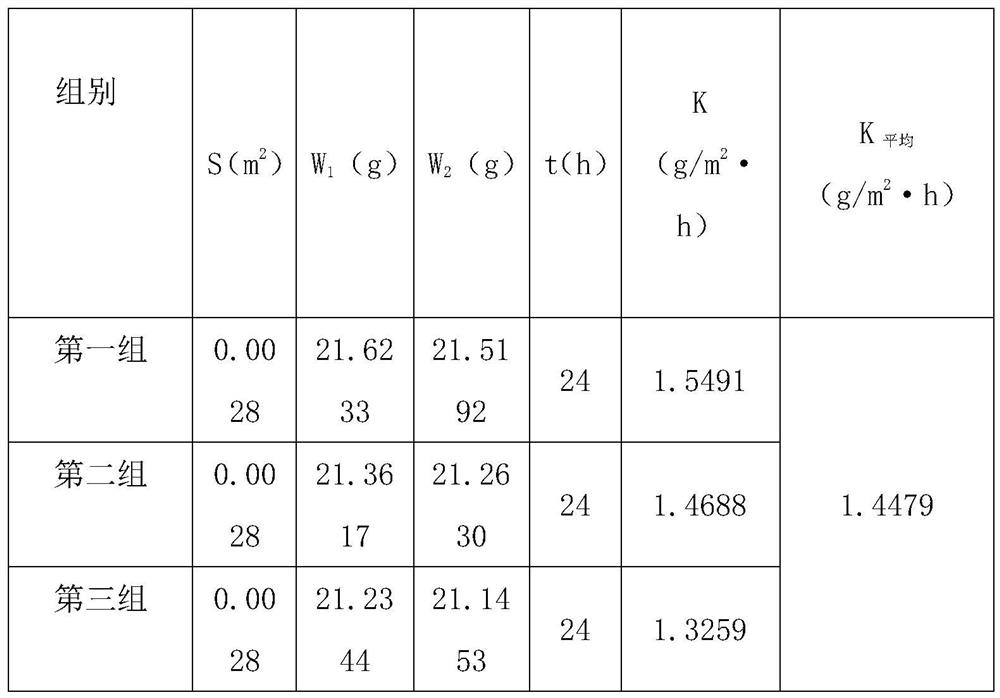

Examples

Embodiment 1

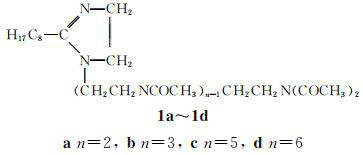

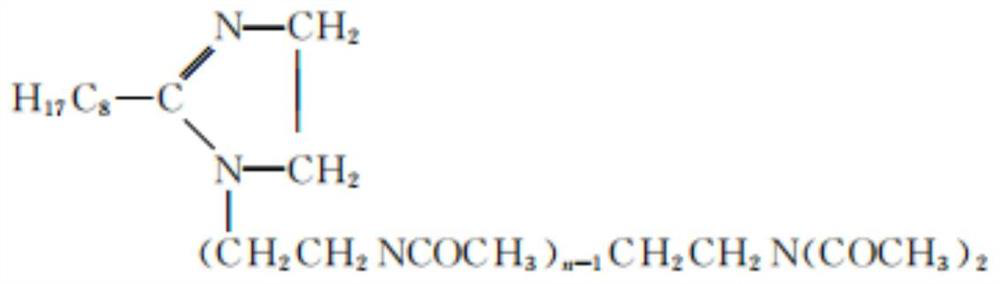

[0018] The galvanizing corrosion inhibitor in the mixed acid medium includes solute and solvent: the solute is composed of the following components, each component is in parts by weight: 10 parts of dodecyl dimethyl benzyl ammonium chloride, 5 parts of nicotinic acid, 5 parts of acridine, 6 parts of berberine, 10 parts of imidazoline amide, 20 parts of sodium polyacrylate; the solvent is a mixed solution of hydrochloric acid and oxalic acid, and the volume ratio is 1:6.

[0019] Preparation method: weigh each component according to the above parts by weight, dissolve the solute in the solvent, and stir and mix evenly.

Embodiment 2

[0021] The galvanizing corrosion inhibitor in the mixed acid medium includes solute and solvent: the solute is composed of the following components, each component is in parts by weight: 15 parts of dodecyl dimethyl benzyl ammonium chloride, 10 parts of nicotinic acid 8 parts, 8 parts of acridine, 7 parts of berberine, 15 parts of imidazoline amide, 30 parts of sodium polyacrylate; the solvent is a mixed solution of hydrochloric acid and oxalic acid consisting of the following components, each component is by weight: the ratio is 1:6.

Embodiment 3

[0023] The galvanizing corrosion inhibitor in the mixed acid medium includes solute and solvent: the solute is composed of the following components, each component is in parts by weight: 20 parts of dodecyl dimethyl benzyl ammonium chloride, 15 parts of nicotinic acid 10 parts of acridine, 8 parts of berberine, 20 parts of imidazoline amide, and 40 parts of sodium polyacrylate; the solvent is a mixed solution of hydrochloric acid and oxalic acid, and the volume ratio is 1:6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| descaling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com