Composite wood board splicing and gluing equipment for building construction

A composite wood board and building construction technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as poor bonding quality, low manual operation efficiency, and uneven force applied by manual extrusion bonding. To achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

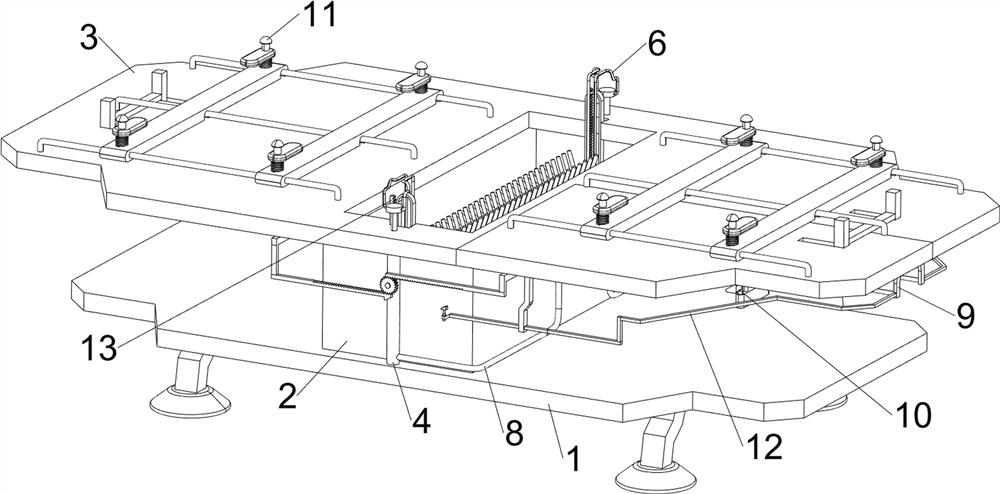

[0027] A kind of equipment for splicing and gluing composite wood boards for building construction, such as Figure 1 to Figure 6 As shown, it includes a bottom plate 1, a material storage box 2, a support plate 3, a piston cylinder 4, a piston rod 5, a connecting frame 6, a brush 7, a hydraulic mechanism 8, a pushing mechanism 9 and a reset mechanism 10, and the top of the bottom plate 1 is provided with a storage Material box 2, the top of the material storage box 2 is provided with a support plate 3, the top of the bottom plate 1 is symmetrically provided with a piston cylinder 4, and the top of the piston cylinder 4 is slidably provided with a piston rod 5, and the piston rod 5 is slidably connected with the support plate 3 , the upper part of the piston rod 5 is left and right symmetrically provided with a connecting frame 6, a rotating brush 7 is arranged between the connecting frame 6, a hydraulic mechanism 8 is arranged on the top of the supporting plate 3, and a pushin...

Embodiment 2

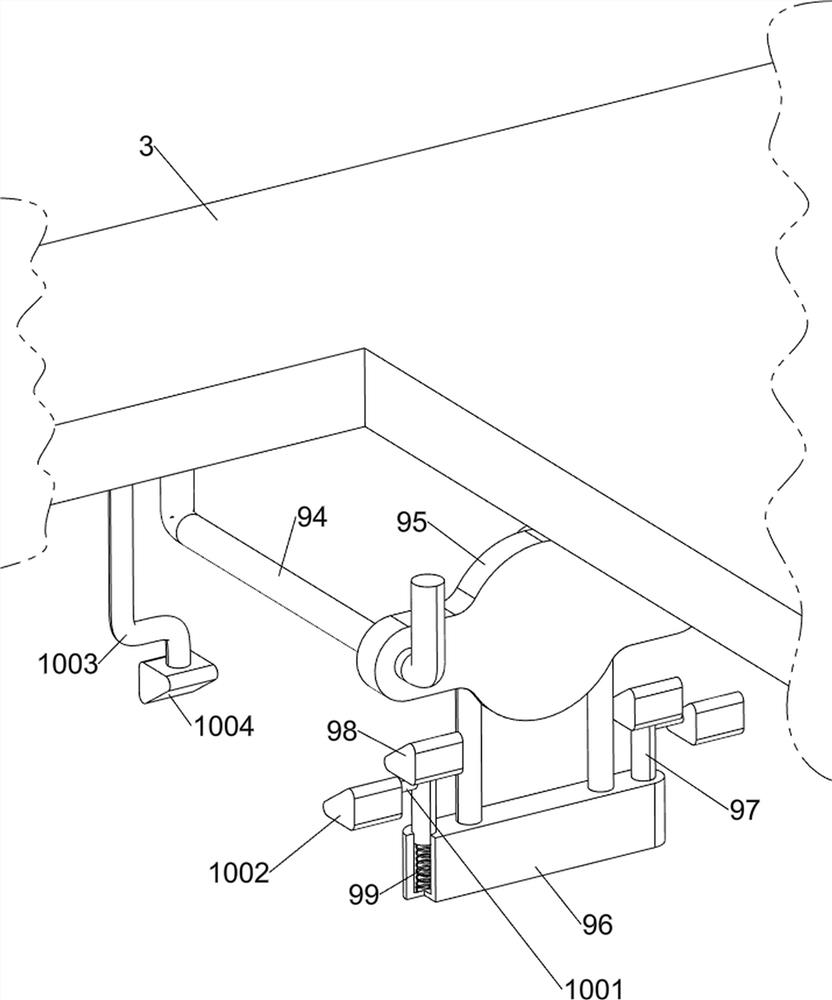

[0033] On the basis of Example 1, such as Figure 7 to Figure 10As shown, a clamping mechanism 11 is also included, and the clamping mechanism 11 includes a guide rod 1101, a slide plate 1102, a second fixed rod 1103, a block 1104 and a third spring 1105, and the left and right sides of the top of the support plate 3 are provided with 3 Two guide rods 1101 are movable on the front side guide rod 1101, and two slide plates 1102 are movable. The slide plate 1102 cooperates with the two guide rods 1101 on the rear side. The upper sliding type is provided with a locking block 1104 , and a third spring 1105 is connected between the bottom of the locking block 1104 and the second fixing rod 1103 .

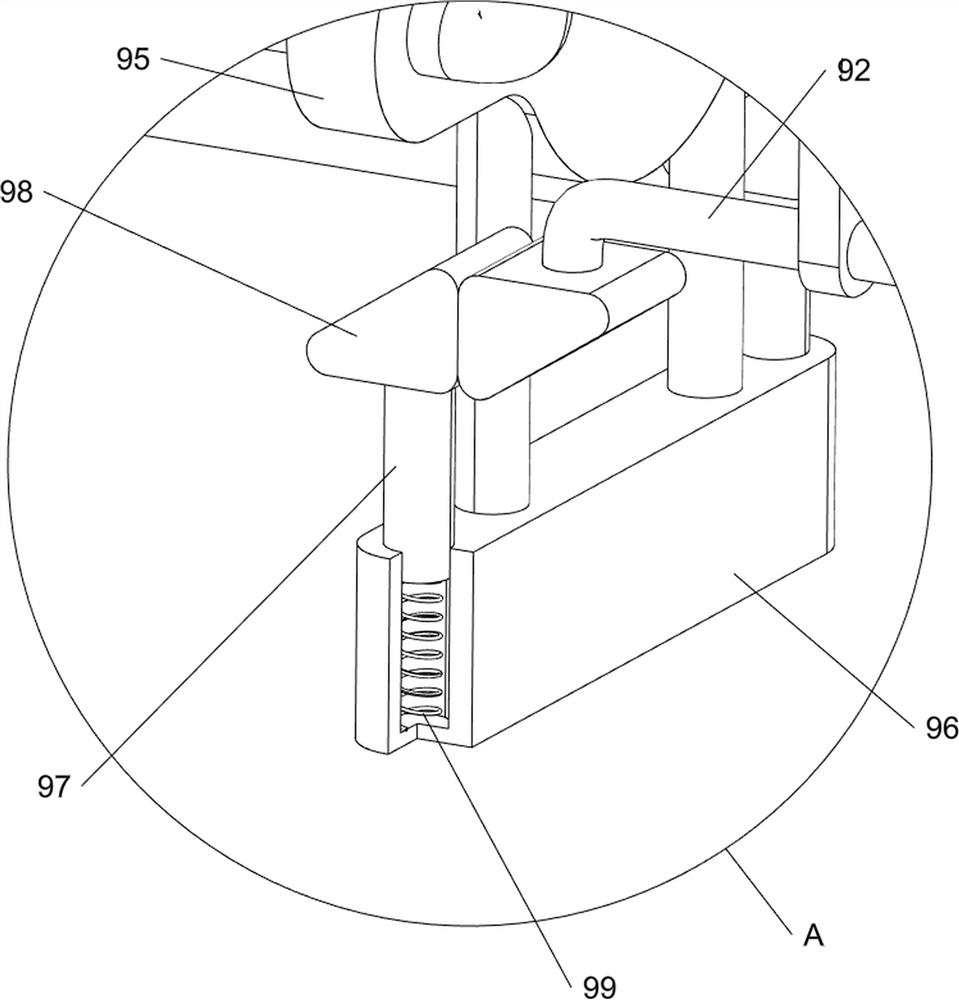

[0034] Also include mobile mechanism 12, mobile mechanism 12 includes special-shaped bar 1201, guide bar 1202, circular tube 1203, clamp bar 1204, the 4th spring 1205, first gear 1206 and special-shaped rack 1207, special-shaped frame 92 front and back both sides There is a special-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com