Ceramic matrix composite turbine guide blade with turbulent flow structures and preparation method thereof

A technology of turbine guide blades and composite materials, which is applied in the direction of blade support elements, mechanical equipment, machines/engines, etc., can solve the problems of difficult spoiler column array structure and shaping, to ensure cooling effect, improve temperature resistance, Effect of Good Physicochemical Compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

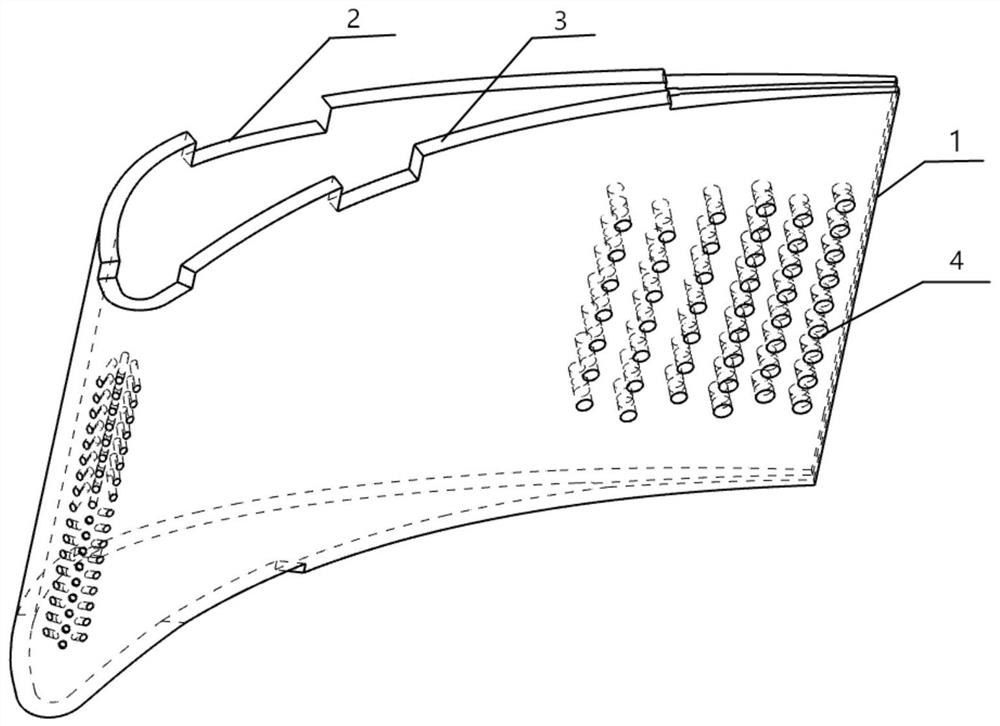

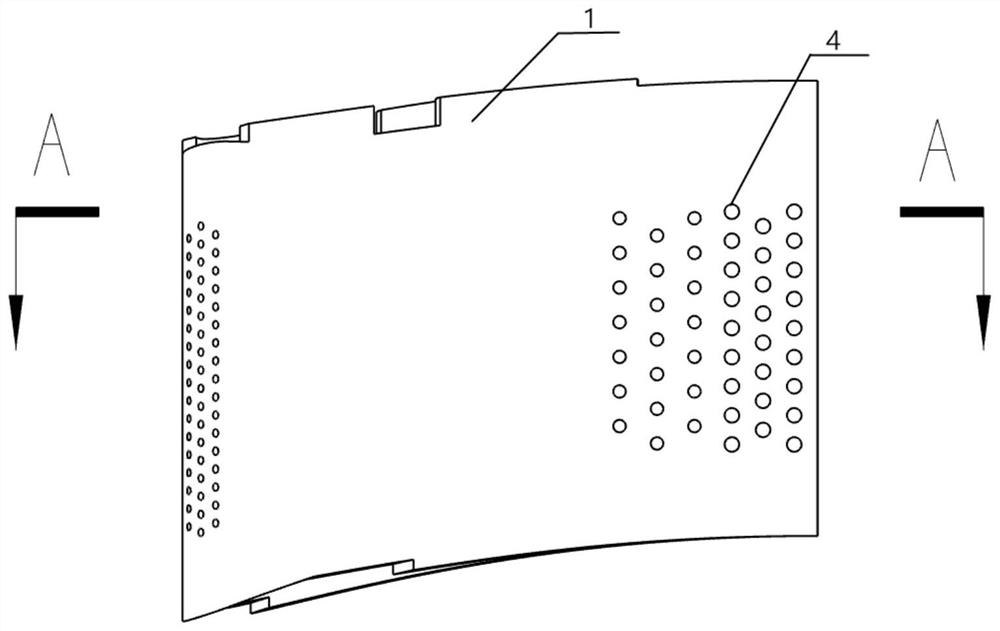

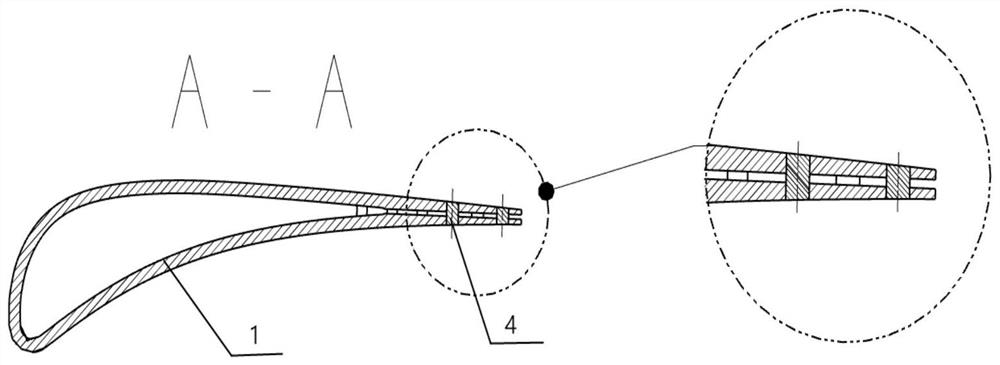

[0045] A ceramic matrix composite turbine guide vane with a spoiler structure, the preparation method of which comprises the following steps:

[0046] (1) Using electrode graphite as the raw material, design and prepare the inner mold according to the profile size of the inner cavity of the guide vane, and then design and prepare the vane pot 3 mold and the vane back 2 according to the profile dimensions of the vane pot and the vane back of the guide vane respectively Mold; wherein, the wall thickness of the inner mold, the 3 molds of the leaf pot and the 2 molds of the leaf back is 4mm, and a large number of vent holes with a diameter of 4mm are arranged on the inner mold, the 3 molds of the leaf basin and the 2 molds of the leaf back;

[0047] (2) Wrap the 2.5-dimensional silicon carbide fiber woven cloth on the outer surface of the inner mould, the thickness of which is 1.1 times the design thickness of the guide vane, and then cover it with the leaf pot 3 mold and the leaf ...

Embodiment 2

[0054] A ceramic matrix composite turbine guide vane with a spoiler structure, the preparation method of which comprises the following steps:

[0055] (1) Using electrode graphite as the raw material, design and prepare the inner mold according to the profile size of the inner cavity of the guide vane, and then design and prepare the vane pot 3 mold and the vane back 2 according to the profile dimensions of the vane pot and the vane back of the guide vane respectively Mold; wherein, the wall thickness of the inner mold, the leaf pot 3 mold and the leaf back 2 mold is 2.5mm, and there are a large number of air holes with a diameter of 3mm on the inner mold, the leaf basin 3 mold and the leaf back 2 mold;

[0056] (2) Wrap the two-dimensional plain weave carbon fiber woven cloth on the outer surface of the inner mold. The thickness of the winding is 1.05 times the design thickness of the guide vane, and then cover it with the leaf pot 3 mold and the leaf back 2 mold, and then use...

Embodiment 3

[0063] A ceramic matrix composite turbine guide vane with a spoiler structure, the preparation method of which comprises the following steps:

[0064] (1) Using electrode graphite as the raw material, design and prepare the inner mold according to the profile size of the inner cavity of the guide vane, and then design and prepare the vane pot 3 mold and the vane back 2 according to the profile dimensions of the vane pot and the vane back of the guide vane respectively Mold; wherein, the wall thickness of the inner mold, the 3 molds of the leaf pot and the 2 molds of the leaf back is 8mm, and a large number of vent holes with a diameter of 8mm are arranged on the inner mold, the 3 molds of the leaf basin and the 2 molds of the leaf back;

[0065] (2) Wrap the two-dimensional satin silicon carbide fiber woven cloth on the outer surface of the inner mould, the thickness of which is 1.2 times the design thickness of the guide vane, then cover it with the leaf pot 3 mold and the lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com