Intelligent food material processor capable of automatically dehydrating according to height and the moisture content of food materials

A water content and processor technology, which is applied in dry cargo handling, dryers, food science, etc., can solve the problems of soup splashing around, liquid splashing around aluminum foil bags, etc., to achieve dehydration operation and improve automation. Effectiveness of production levels, precise monitoring and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

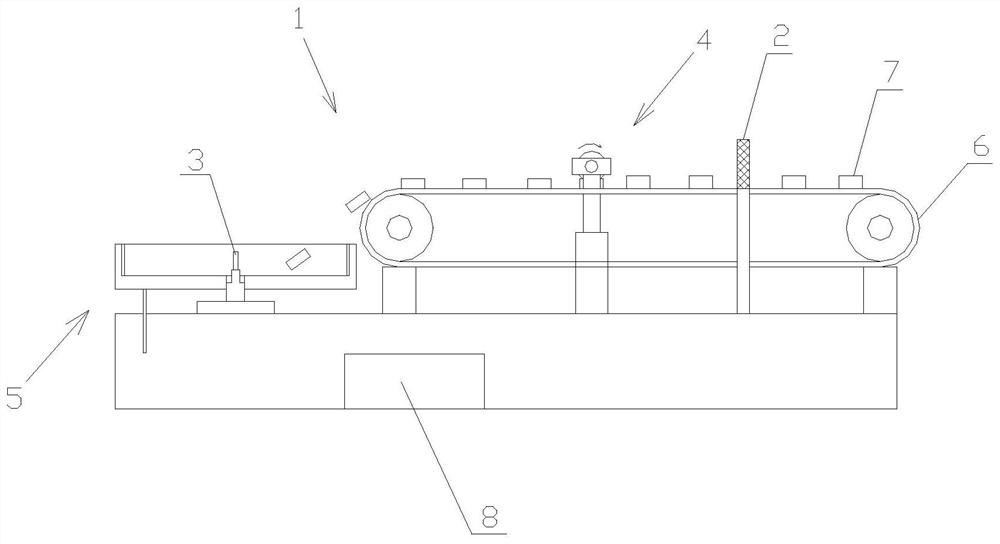

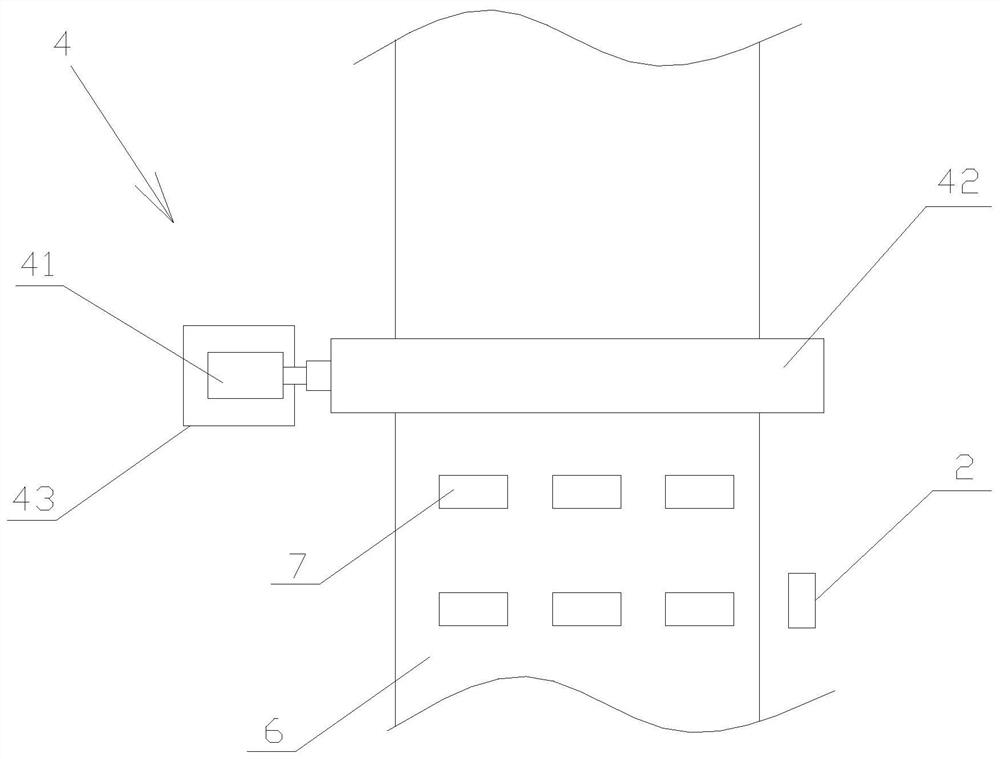

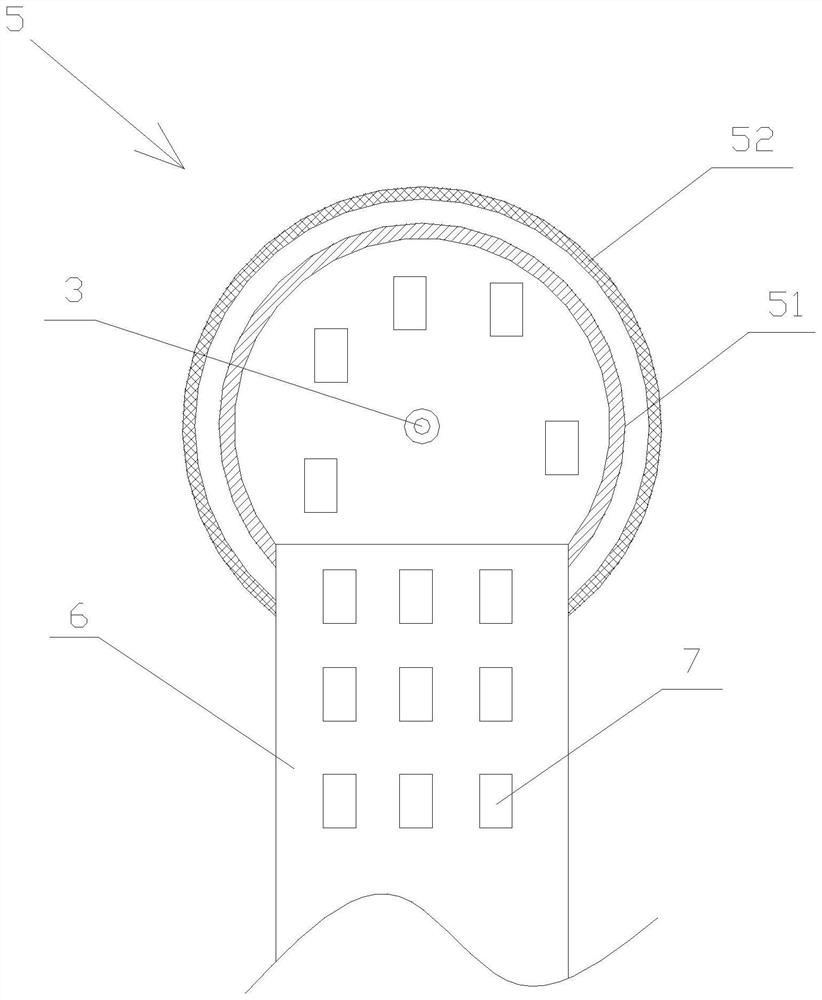

[0025] like figure 1 , figure 2 as well as image 3 As shown, an intelligent processing machine for automatically dehydrating food according to the height and water content of the food, including a first conveying platform 1, a height detector 2, a moisture detector 3, a roller extrusion device 4 and a centrifugal rotating device 5, the A conveyor belt 6 is provided on the first conveying platform 1 for placing and conveying food materials 7 to be processed. The conveying direction of the belt 6 is arranged sequentially, the height detector 2 is used to detect the height of the food material 7 on the conveyor belt, and the roller squeezing device 4 can adjust the rolling height according to the height of the food material, and roll and squeeze the food material , the centrifugal rotating device 5 is cooperatingly installed on the output end of the first conveying platform 1, and the moisture detector 3 is cooperatingly installed in the centrifugal rotating device 5; There ...

Embodiment 2

[0031] as shown in the picture figure 2 , image 3 , Figure 4 and Figure 5 As shown, an intelligent processing machine for automatically dehydrating food according to the height and water content of the food, including a first conveying platform 1, a height detector 2, a moisture detector 3, a roller extrusion device 4 and a centrifugal rotating device 5, the A conveyor belt 6 is provided on the first conveying platform 1 for placing and conveying food materials 7 to be processed. The conveying direction of the belt 6 is arranged sequentially, the height detector 2 is used to detect the height of the food material 7 on the conveyor belt, and the roller squeezing device 4 can adjust the rolling height according to the height of the food material, and roll and squeeze the food material , the centrifugal rotating device 5 is cooperatingly installed on the output end of the first conveying platform 1, and the moisture detector 3 is cooperatingly installed in the centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com