Light skid-mounted urea pyrolysis pneumatic SCR tail gas treatment system and method and application

A technology for tail gas treatment and pyrolysis gas, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation. The effect of small area, small amount of installation work and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0037] The raw materials used in the present invention, if no special instructions, are conventional commercially available products, the methods used in the present invention, if no special instructions, are conventional methods in this area, and the quality of each material used in the present invention is routine use quality. Structures, connections, etc. that are not described in detail in the present invention can be understood as conventional technical means in the art.

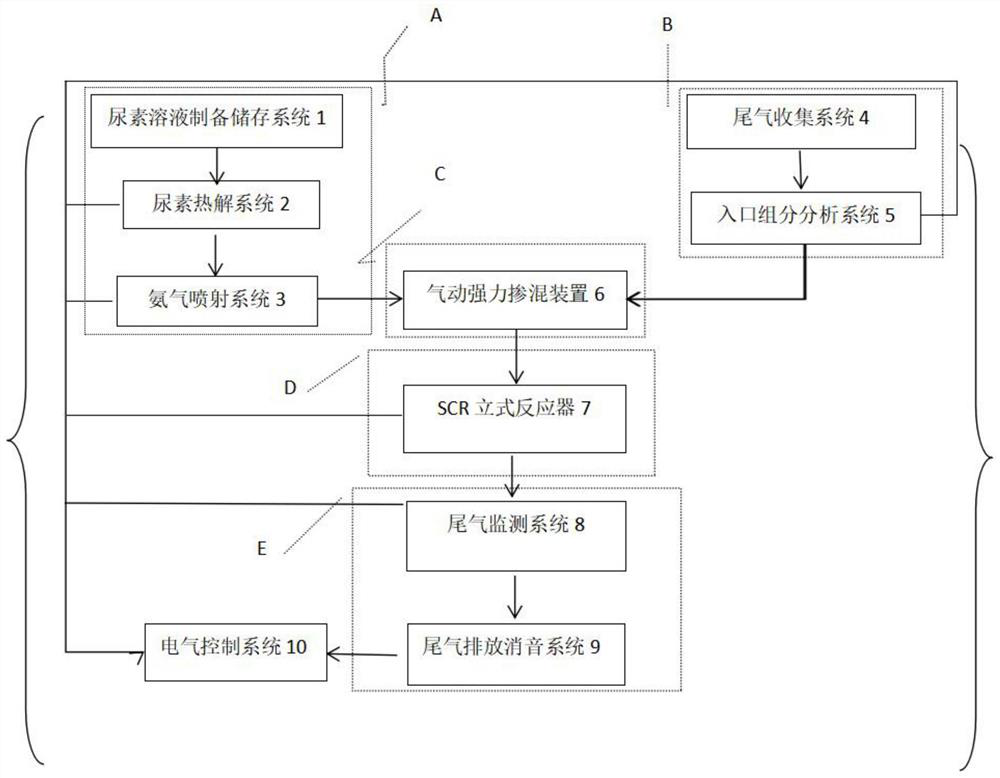

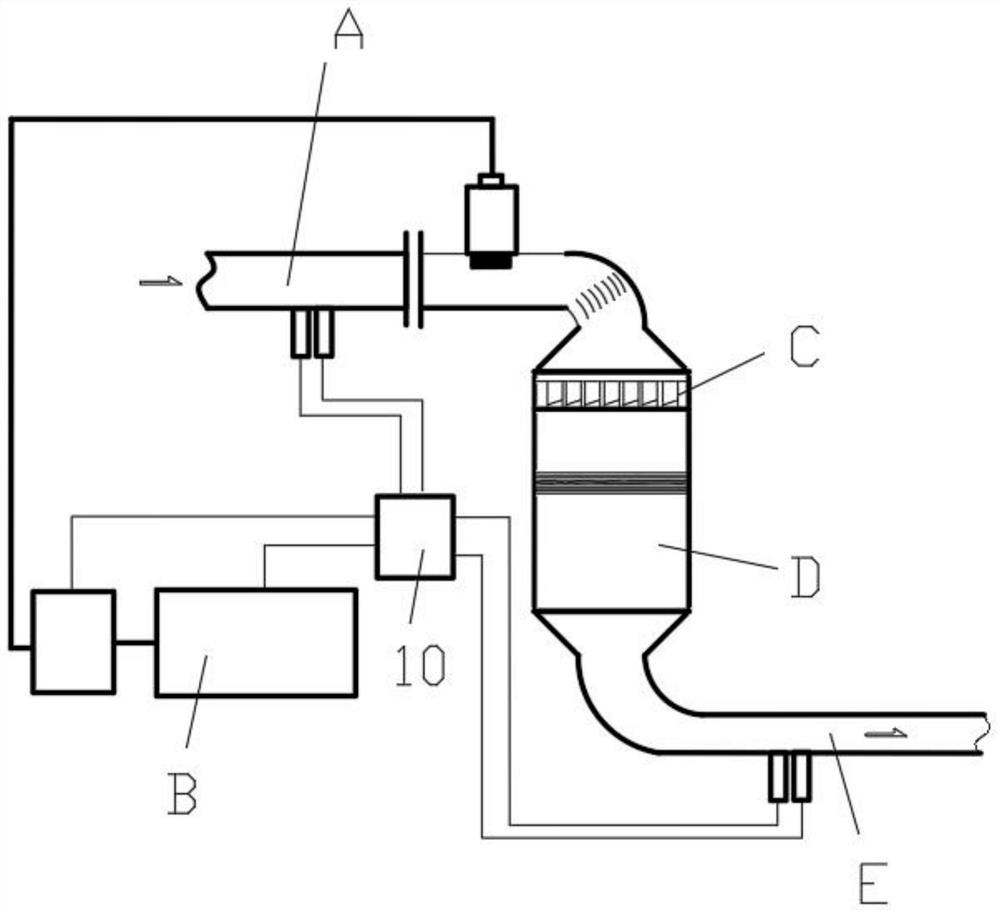

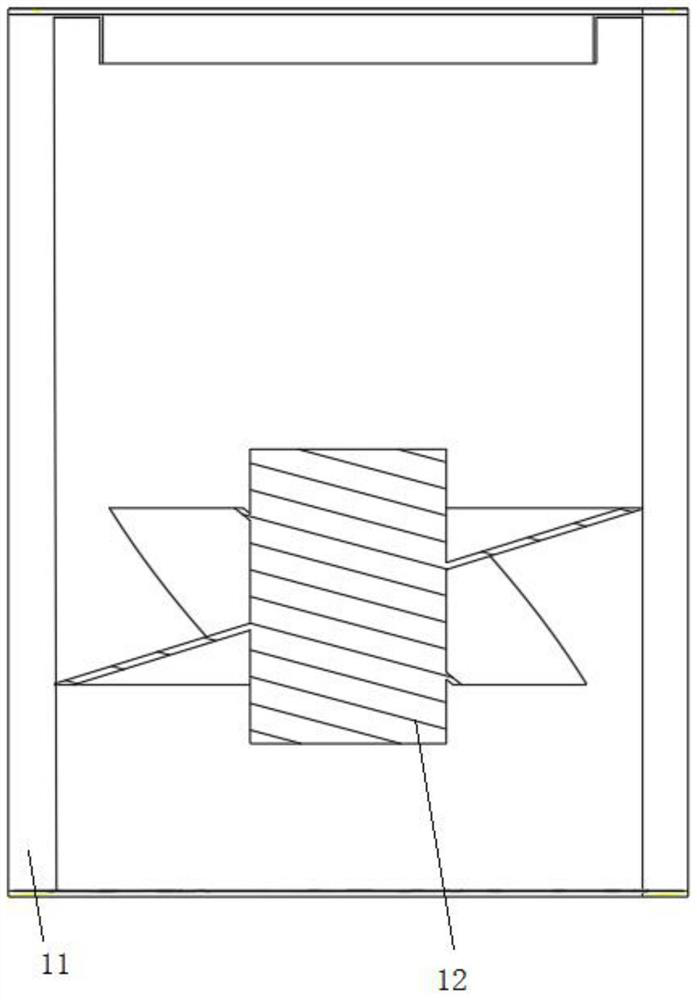

[0038] A light skid-mounted urea pyrolysis pneumatic SCR tail gas treatment system, such as figure 1 , figure 2As shown, the treatment system includes a reducing agent preparation system A, an exhaust gas component analysis system B, a pneumatic intensive blending sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com