Waste-heat-available mixing device based on rare earth waste and processing technology of waste-heat-available mixing device

A rare earth waste and mixing device technology, applied in the field of rare earth, can solve the problems of affecting the processing efficiency of rare earth waste, slow mixing efficiency of the mixing device, and affecting the treatment of rare earth waste, so as to save mixing time, realize effective filtration, and facilitate Effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

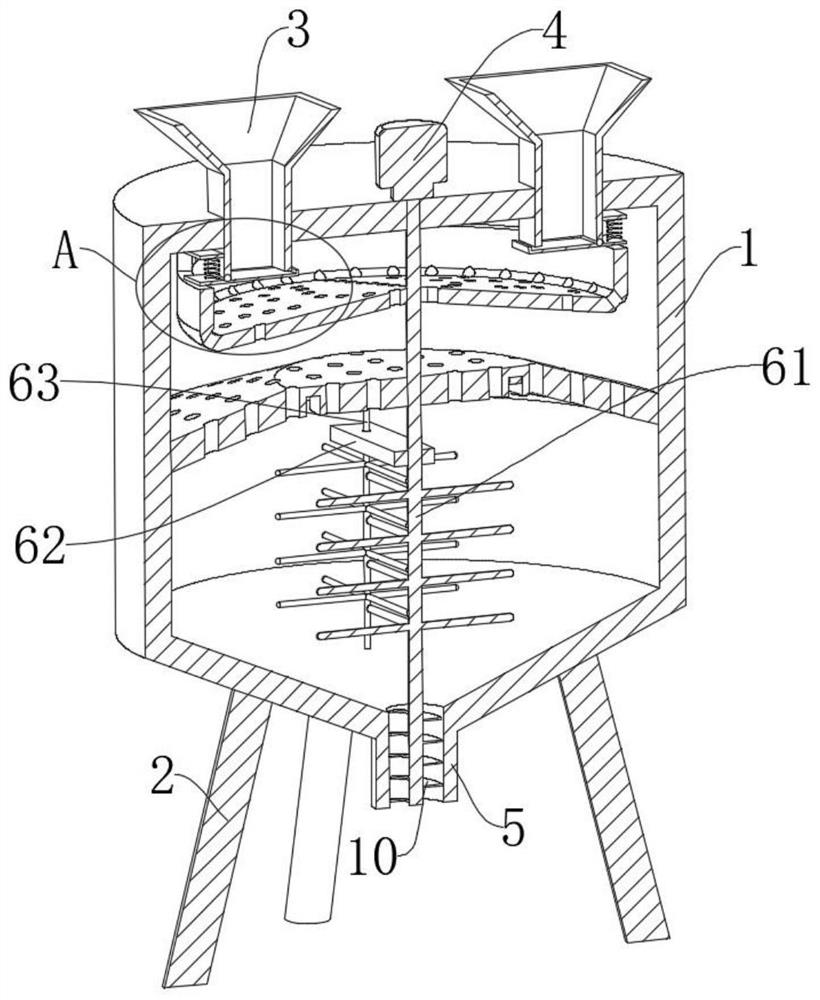

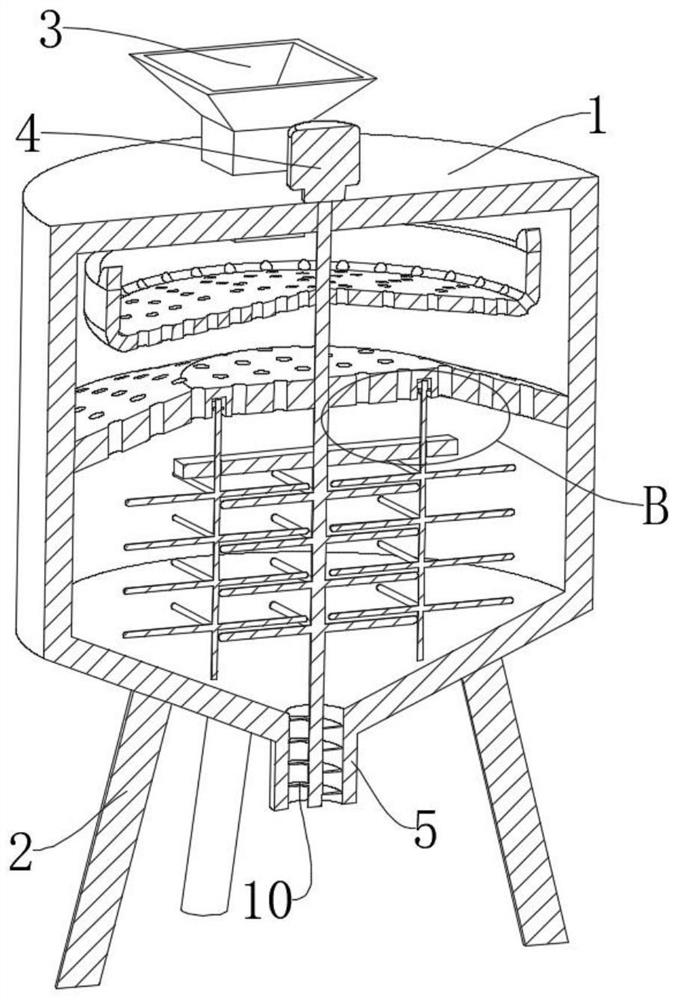

[0039] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

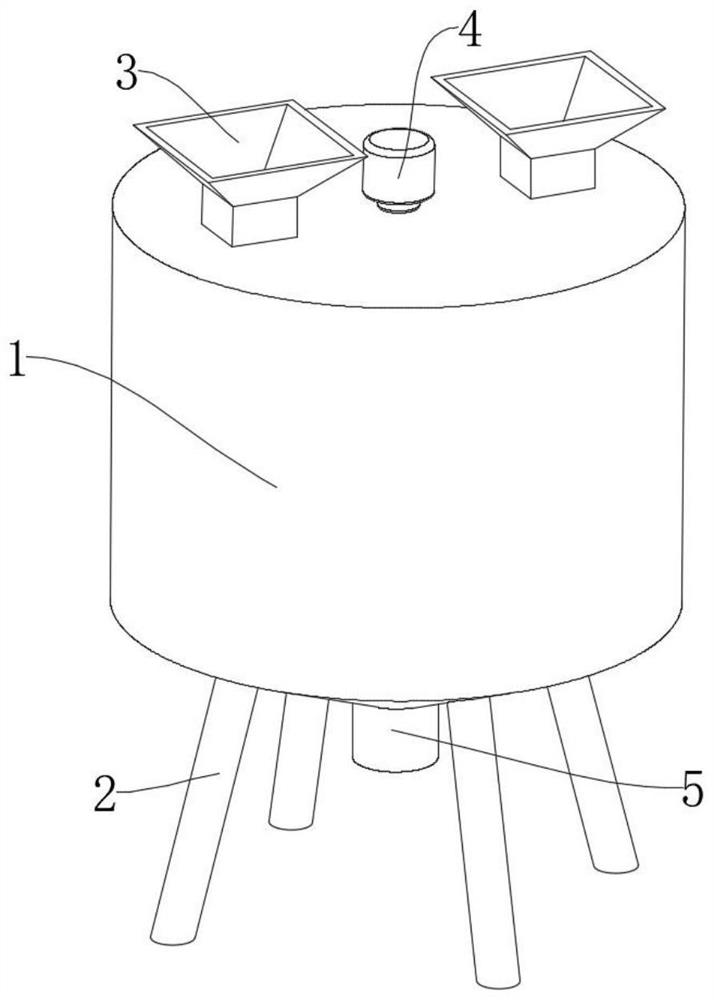

[0040] Refer Figure 1-7 , Waste heat available for rare earth waste, including:

[0041] The can body 1, the bottom of the can body 1 is fixedly attached to the leg 2, and the top of the can body 1 is fixedly connected to the fed strip 3, the top of the can body 1 is fixedly connected to the servo motor 4, and the output shaft of the servo motor 4 is fixedly connected to the drive. Institution 8, drive mechanism 8 is the working transmission power of the entire device;

[0042] The mixing mechanism 6, the mixing mechanism 6 is mounted at the bottom of the drive mechanism 8, and the mixing mechanism 6 is used to perform a mixed operation;

[0043] The filter assembly 7, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com