Waterborne polyurethane dispersion synthesis reaction kettle

A water-based polyurethane, synthesis reaction technology, applied in mixers, shaking/oscillating/vibrating mixers, processes below atmospheric pressure, etc., can solve the problem of poor sealing, low efficiency, and difficulty in ensuring that the inside of the reactor box is in a vacuum state and other problems, to avoid gas discharge, effective sealing effect, and improve stirring and mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

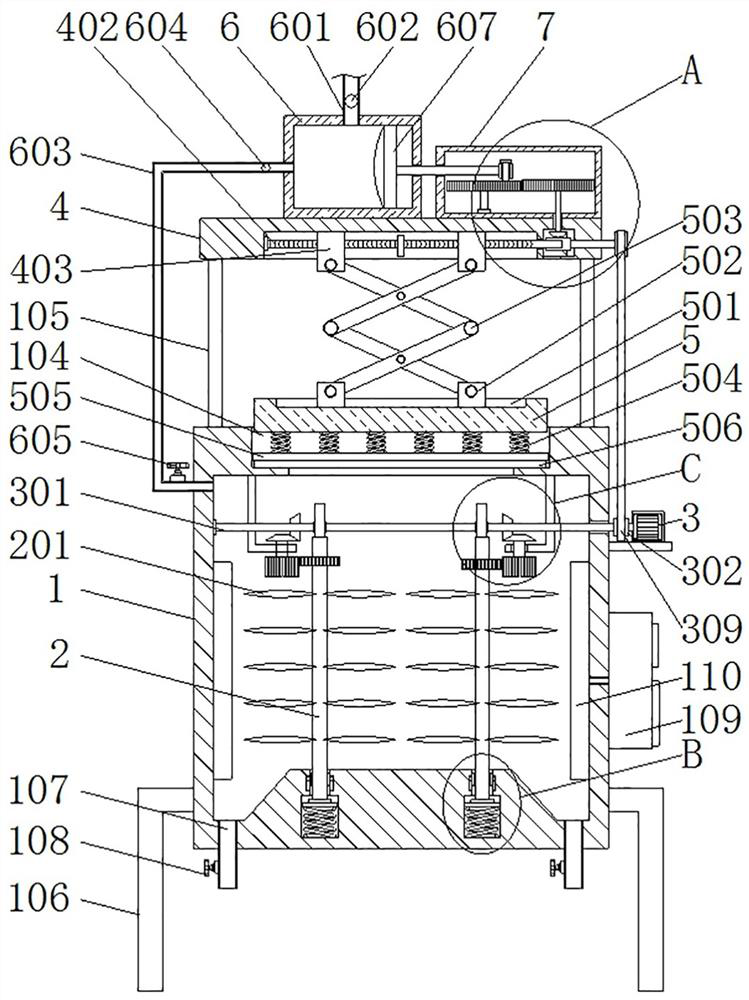

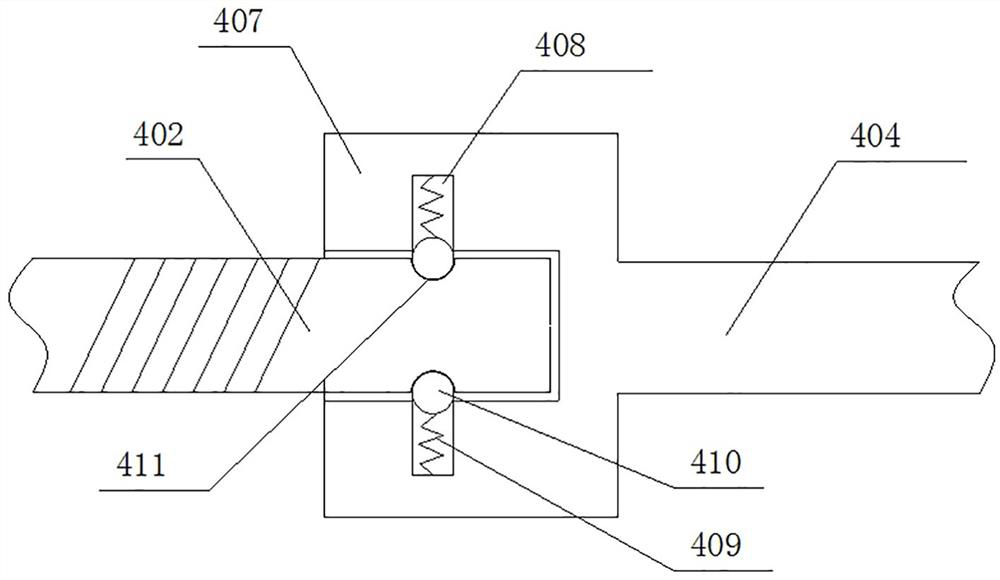

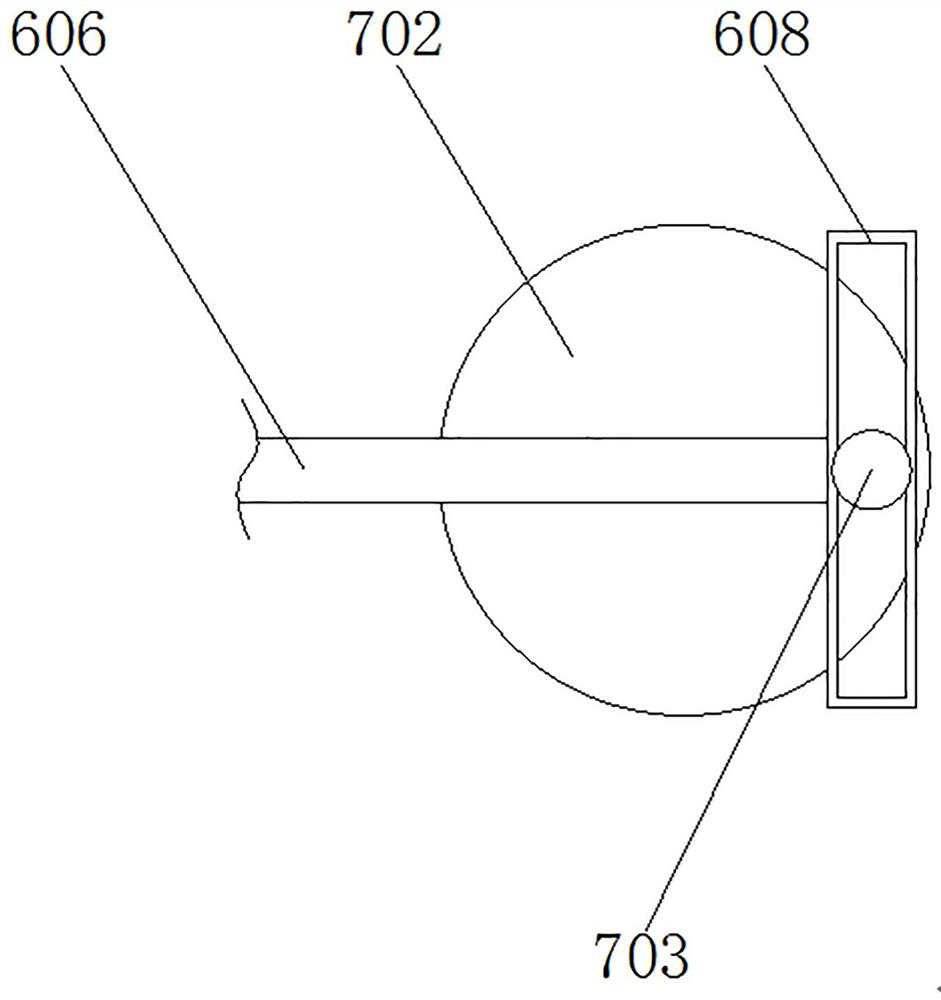

[0024] see Figure 1 to Figure 6, the present invention provides a technical solution: a water-based polyurethane dispersion synthesis reactor, comprising a reactor box 1, a stirring rod 2 and a cover plate 5, the inside of the reactor box 1 is provided with a spring groove 101 near the lower position, The inner side of the spring groove 101 is fixedly installed with a No. 1 telescopic spring 102, and the inside of the reactor casing 1 is positioned at the top of the spring groove 101 to provide a No. 1 chute 103, and the outer surface of the stirring rod 2 is fixedly equipped with a plurality of stirring blades 201, and the stirring rod No. 1 gear 202 is fixedly ins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap