Welding method for applying copper water heat pipe to aluminum plate

A welding method and heat pipe technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as poor contact and large contact thermal resistance, and achieve the effects of improving welding efficiency, ensuring welding quality, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

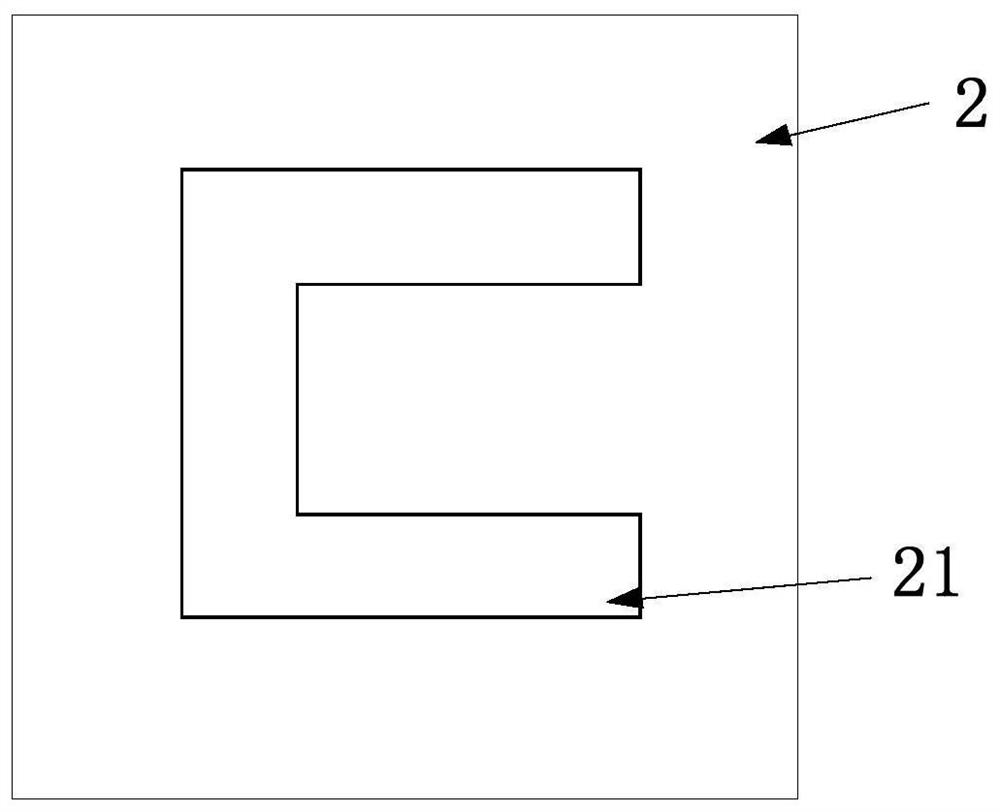

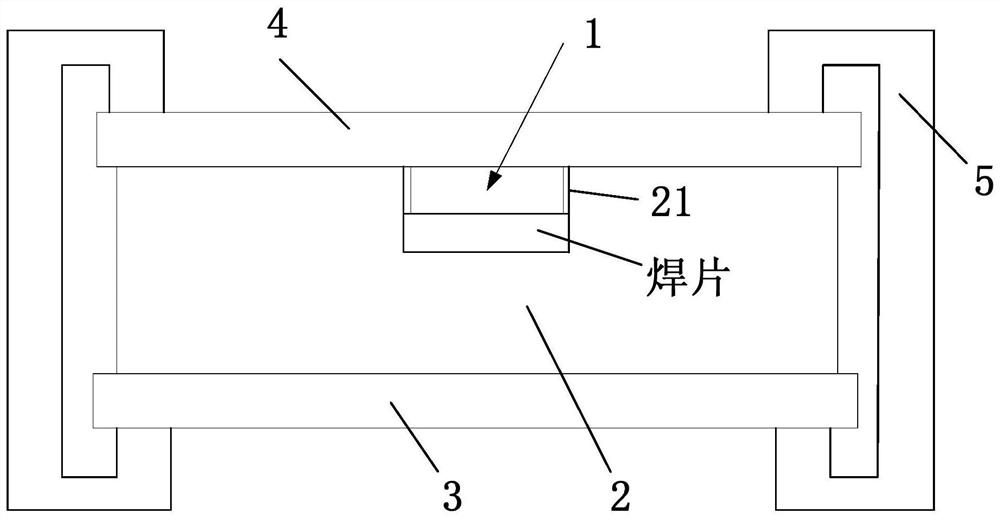

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with embodiment.

[0028] The invention proposes a copper-water heat pipe applied to a welding process on an aluminum plate to meet the heat dissipation requirements of high-power devices. Compared with the traditional heat dissipation method, the thermal conductivity of the original aluminum alloy is increased from 188W / (m-K) to 104~105W / (m-K), which is hundreds or even thousands of times that of ordinary metal materials, and improves the thermal conductivity in vacuum environment. The heat dissipation of components is difficult to meet the heat dissipation requirements of a single machine.

[0029] The copper water heat pipe is applied to the welding method on the aluminum plate, which specifically includes the following steps:

[0030] Step 1. Use a heat press to press the cylindrical heat pipe into a flat heat pipe. The thickness of the flat heat pipe after pressing is 3mm, and the flatness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap