Ternary positive electrode material, lithium ion battery positive electrode plate and application of lithium ion battery positive electrode plate

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of difficult ternary material performance optimization, difficulty in compatibility, etc., to improve gas production problems, performance optimization, and improved packaging The effect of overlay sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Another technical solution discloses the preparation of a positive electrode material for a lithium ion battery, specifically a method for preparing a ternary positive electrode material coated with Co and Ti by ball milling. The method comprises the following steps: step 1, three-dimensionally mechanically mixing the 523-type ternary precursor with battery-grade lithium carbonate, then sintering in an air-ventilated sintering furnace at 600-700°C, and grinding and crushing after cooling to obtain 523 ternary Yuan cathode material; Step 2, combine 523 ternary cathode materials with cobalt oxide, battery grade lithium carbonate, and analytically pure grade TiO 2 The additives are mixed in a high-energy ball mill, the mixed samples are taken out and washed with distilled water, and after sintering, the samples are taken out and ground to obtain a finished product. The preparation method can perform LiCoO on the surface of the ternary material 2 coating, and use Ti on LiC...

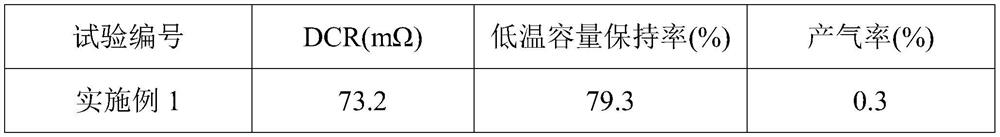

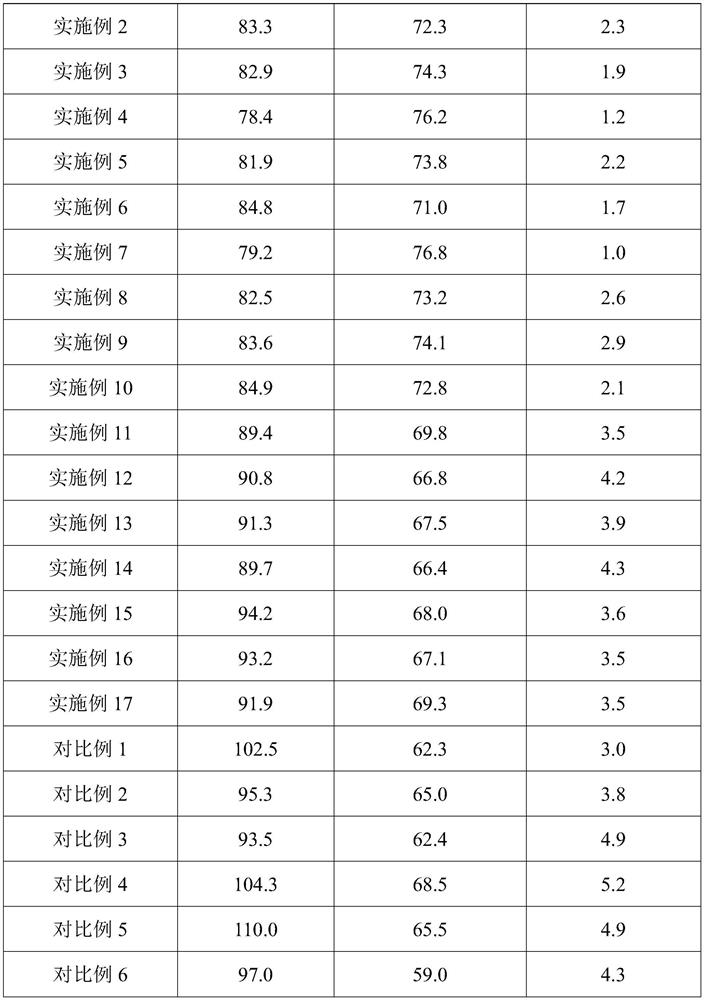

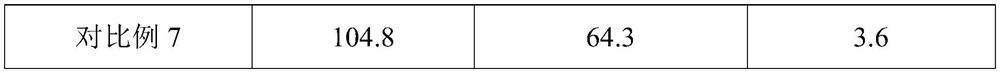

Embodiment 1

[0051] This embodiment provides a ternary positive electrode material, in terms of mass percentage, the ternary positive electrode material includes:

[0052] Nickel cobalt manganese ternary material 99.6wt%

[0053] CoOOH 0.2wt%

[0054] Al 2 o 3 0.2 wt%.

[0055] The nickel-cobalt-manganese ternary material is secondary spherical LiNi 0.55 co 0.15 mn 0.3 o 2 , with a median particle size of 10 μm.

[0056] The preparation method of the ternary positive electrode material includes the following steps: heating and sintering the nickel-cobalt-manganese ternary material at a heating rate of 4°C / min, and mixing CoOOH with the nickel-cobalt-manganese ternary material when the temperature is raised to 350°C Ternary material, to obtain a mixture; when the temperature rises to 600°C, mix Al 2 o 3 and the mixture, continue to heat up to 630° C., and sinter for 10 hours to obtain the ternary positive electrode material.

[0057] This embodiment provides a lithium ion batter...

Embodiment 2

[0059] This embodiment provides a ternary positive electrode material, in terms of mass percentage, the ternary positive electrode material includes:

[0060] Nickel cobalt manganese ternary material 99wt%

[0061] co 2 o 3 0.5wt%

[0062] h 3 BO 3 0.5 wt%.

[0063] The nickel-cobalt-manganese ternary material is secondary spherical LiNi 0.5 co 0.15 mn 0.35 o 2 , with a median particle size of 20 μm.

[0064] The preparation method of the ternary positive electrode material includes the following steps: heating and sintering the nickel-cobalt-manganese ternary material at a heating rate of 2°C / min, and mixing Co 2 o 3 and the nickel-cobalt-manganese ternary material to obtain a mixture; when the temperature rises to 625°C, mix H 3 BO 3 and the mixture, continue to heat up to 640° C., and sinter for 15 hours to obtain the ternary positive electrode material.

[0065] This embodiment provides a lithium ion battery positive electrode sheet, the lithium ion battery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com