Lithium titanium composite oxide, modified lithium titanate material, and preparation method and application thereof

A technology of lithium-titanium composite and non-toxic lithium titanate, which is applied in the direction of lithium batteries, electrical components, battery electrodes, etc., can solve the problem of the water absorption of amorphous porous carbon is not easy to bake out, the conductive carbon black cannot form a stable SEI film, and high temperature cracking Complicated technical production process and other issues, to achieve the effect of improving battery gas production and cycle, improving strong hygroscopicity, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

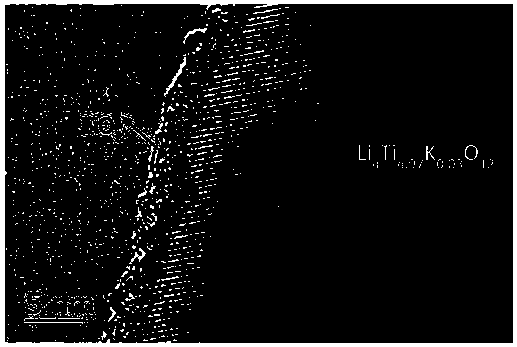

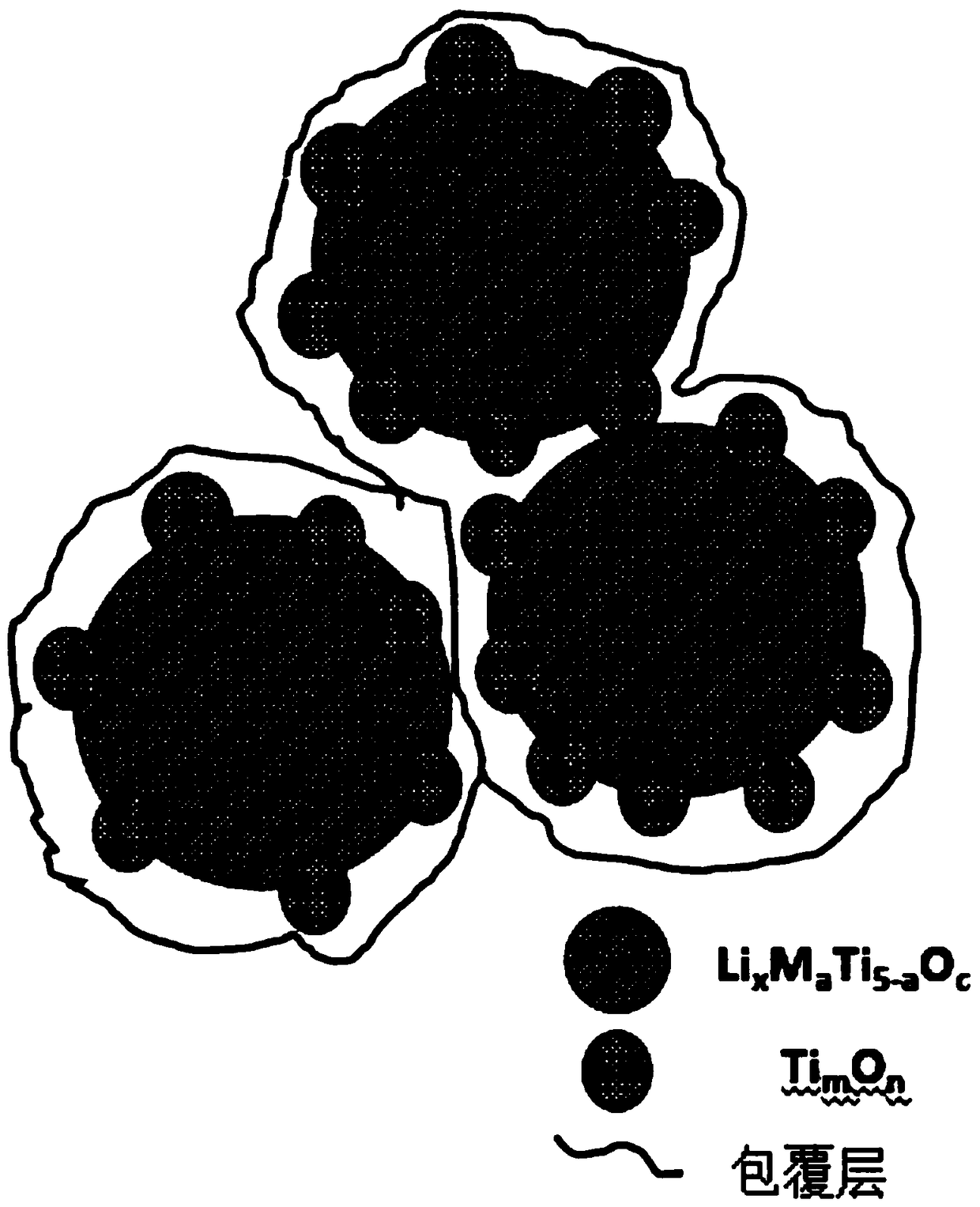

[0048] Lithium carbonate, titanium dioxide, and dopants can be prepared according to the 4 Ti 4.97 K 0.03 o 12 +10%TiO 2 The lithium-titanium composite oxide (referring to the lithium-titanium composite oxide, TiO 2 The mole fraction of Li 4 Ti 4.97 K 0.03 o 12 The ratio of the mole fraction is 10%) to mix the raw materials, in the air atmosphere, pre-calcined at 500°C for 5h, calcined at 700°C for 10h, in the reducing atmosphere of hydrogen and argon (wherein, argon and The mass ratio of hydrogen is 95:5) and the surface is reduced at 650° C. for 5 hours to obtain the lithium-titanium composite oxide.

[0049] Technical effect: The TEM of the obtained lithium-titanium composite oxide is as follows figure 2 shown, from figure 2 It can be clearly seen that two groups of different selected lattice diffraction fringes are spinel-type Li 4 Ti 4.97 K 0.03 o 12 and anatase TiO 2 .

Embodiment 2

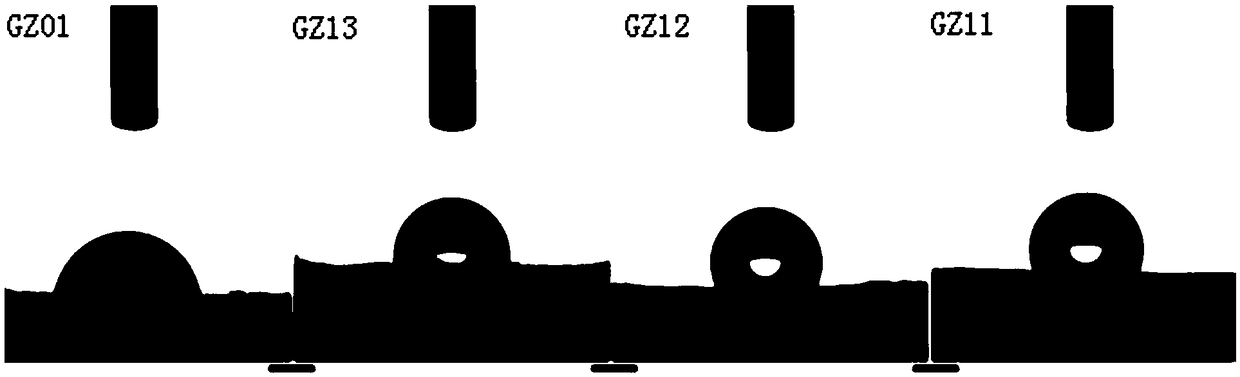

[0051] Disperse the lithium-titanium composite oxide obtained in Example 1 in the oil phase system N-methylpyrrolidone, slowly add aniline monomer, stir for 3 hours, and carry out the polymerization reaction of the surface polymer compound to obtain the modified lithium titanate material , the coating amounts were 1%, 2%, and 3%, respectively, and the hydrophobicity test was carried out on the obtained modified lithium titanate material, and the results were as follows image 3 shown. image 3 Among them, the coating amounts of GZ13, GZ12, and GZ11 were 1%, 2%, and 3%, respectively.

Embodiment 3

[0059] Disperse the lithium-titanium composite oxide obtained in Example 1 in ether in the oil phase system, slowly add vinylpyrrolidone monomer, stir for 5 hours, and carry out the polymerization reaction of the surface polymer compound to obtain the modified lithium titanate material. The amount is 1.5%. The obtained modified lithium titanate material was analyzed by scanning electron microscope, and the results were as follows: Figure 4 shown.

[0060] Technical effect: from Figure 4 It can be seen that the surface of the obtained modified lithium titanate material has clear polymer material boundaries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com