A kind of preparation method of spherical lithium titanate material

A lithium titanate, spherical technology, which is applied in the field of preparation of spherical lithium titanate materials, can solve the problems of limited application and low energy density, and achieve the effects of wide and easy availability of raw materials, increased tap density, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

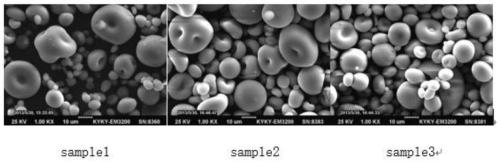

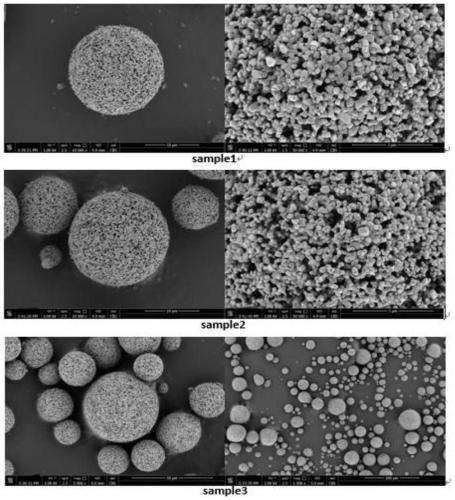

Embodiment 1

[0028] A spherical lithium titanate material whose main component is lithium titanate, coated with a small amount of acidic oxide, and has a relatively low pH value.

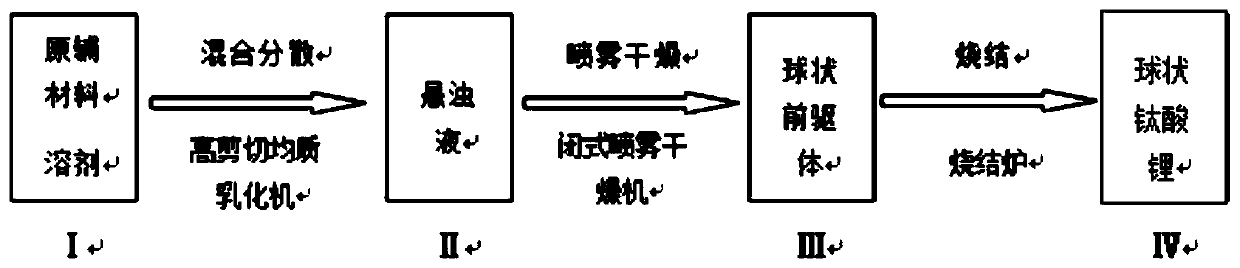

[0029] Preparation methods such as figure 1 As shown, Ⅰ: raw and auxiliary materials, Ⅱ: mixed suspension, Ⅲ: spheroidized precursor after drying, Ⅳ: spherical lithium titanate finished product after sintering, specifically including the following steps:

[0030] 1. Weigh 53.06g of 99.5% lithium acetate and 358.23g of 95% tetrabutyl titanate respectively, that is, according to the molar ratio of Li:Ti=0.8:1, add high-shear homogeneous emulsification containing 617g of ethanol solvent Machine dissolved and mixed for 1 hour to form a uniformly dispersed transparent solution;

[0031] 2. Add 0.27 g of nano-level manganese heptoxide to the solution obtained in step 1, and then mix and disperse for 1 hour through a high-shear homogeneous emulsifier to form a uniformly dispersed suspension;

[0032] 3. Carry out clo...

Embodiment 2

[0035] A spherical lithium titanate material whose main component is lithium titanate, coated with a small amount of acidic oxide, and has a relatively low pH value.

[0036] Concrete preparation method comprises the following steps:

[0037] 1. Weigh 55.71g of 99.5% lithium acetate and 358.23g of 95% tetrabutyl titanate respectively, that is, according to the molar ratio of Li:Ti=0.84:1, add high-shear homogeneous emulsification containing 621g of ethanol solvent Machine dissolved and mixed for 1 hour to form a uniformly dispersed transparent solution;

[0038] 2. Add 0.43 g of nano-scale chromium trioxide to the solution obtained in step 1, and then mix and disperse for 1 hour through a high-shear homogeneous emulsifier to form a uniformly dispersed suspension;

[0039] 3. Carry out closed spray drying of the suspension obtained in step 2, adjust the speed of the peristaltic pump to 8rpm, and the atomization frequency to 30Hz, to obtain a spherical precursor with a spherica...

Embodiment 3

[0042] A spherical lithium titanate material whose main component is lithium titanate, coated with a small amount of acidic oxide, and has a relatively low pH value.

[0043] Concrete preparation method comprises the following steps:

[0044] 1. Weigh 55.71g of 99.5% lithium acetate and 240.16g of 95% tetraethyl titanate respectively, that is, according to the molar ratio of Li:Ti=0.84:1, add high-shear homogeneous emulsification containing 444g of methanol solvent Machine dissolved and mixed for 1 hour to form a uniformly dispersed transparent solution;

[0045] 2. Add 0.41 g of nano-scale chromium trioxide to the solution obtained in step 1, and then mix and disperse for 1 hour through a high-shear homogeneous emulsifier to form a uniformly dispersed suspension;

[0046] 3. Carry out closed spray drying of the suspension obtained in step 2, adjust the speed of the peristaltic pump to 8rpm, and the atomization frequency to 30Hz, to obtain a spherical precursor with a spheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com