Ruthenium-based sputtering target and method for manufacturing same

A sputtering target and sputtering technology, used in sputtering coating, vacuum evaporation coating, ion implantation coating, etc. It is easy to produce particles and other problems, so as to achieve the effect of low anisotropy of the structure, low particle size and high film thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A seed plate of random anisotropic crystals containing a hexagonal close-packed structure of ruthenium metal was prepared. Separately, a ruthenium raw material was prepared. The ruthenium powder (purity is 99.99 mass %) in 5 × 10 -2 After melting in a vacuum environment below Pa, it is solidified to obtain a ruthenium ingot. A ruthenium ingot was pulverized to obtain a pulverized product, which was used as a ruthenium raw material. The raw material of ruthenium is cast ruthenium sheet. Arrange the pulverized material as the ruthenium raw material on the seed plate in a flat shape, at 5×10 -2Each fragment was heated from above in a vacuum environment below Pa to melt it, and then cooled to produce a ruthenium plate having a seed plate in the lower part. Then, the cast ruthenium sheets are arranged flat on the ruthenium plate with the seed plate at the bottom, at 5×10 -2 Each fragment was heated from above in a vacuum environment below Pa to melt it, and then cooled ...

reference example 1

[0088] Ruthenium powder (purity: 99.99% by mass) was used as a reference example.

[0089] (X-ray diffraction)

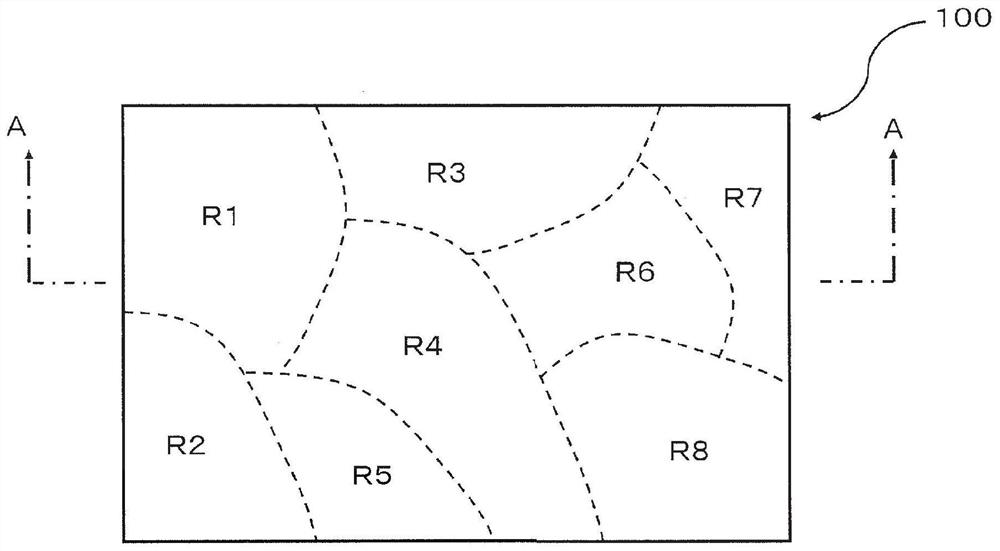

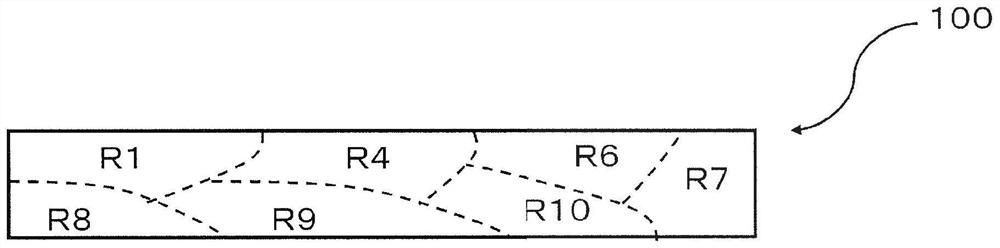

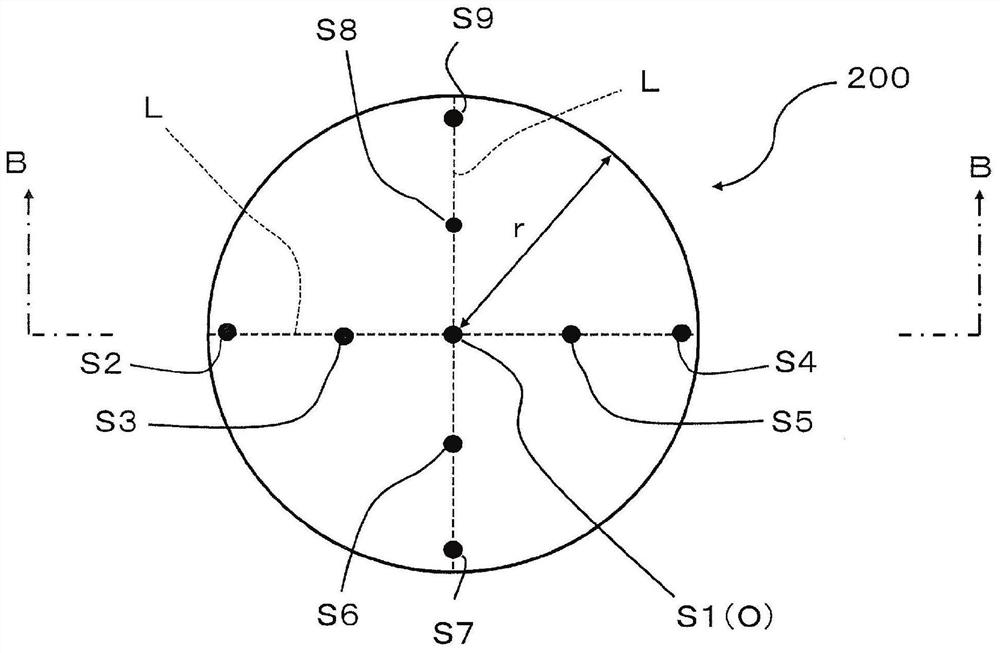

[0090] According to (condition 2), X-ray diffraction (CuKα) was measured about the square plate-shaped Ru sputtering target material of Example 1, Comparative Example 1, and Comparative Example 2, respectively. Regarding Example 1, in Table 1 and Table 2, relative integrated intensities of crystal planes and peaks are summarized for the main peak, the second peak, the third peak, and the fourth peak. P1~P9 in Table 1 and Figure 5 corresponding to P1~P9. In addition, D1~D9 in Table 2 and Image 6 corresponding to D1~D9. Regarding Comparative Example 1, regarding Figure 5 P1~P9 of Image 6 For the main peak, the second peak, the third peak and the fourth peak generated at the measurement sites of D1 to D9, the relative integrated intensity between the crystal plane and the peak does not change, so it is shown in Table 3 Figure 5 P1 and Image 6 The results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com