Magnetic-attraction heavy-throwing type ball mill for preparing zirconium oxide powder and lining thereof

A ball mill and lining technology, applied in the direction of grain processing, etc., can solve the problems of poor sintering activity, poor color continuous adjustability, low manufacturing cost, etc., achieve the effect of uniform particle size, shorten crushing time, and enhance impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

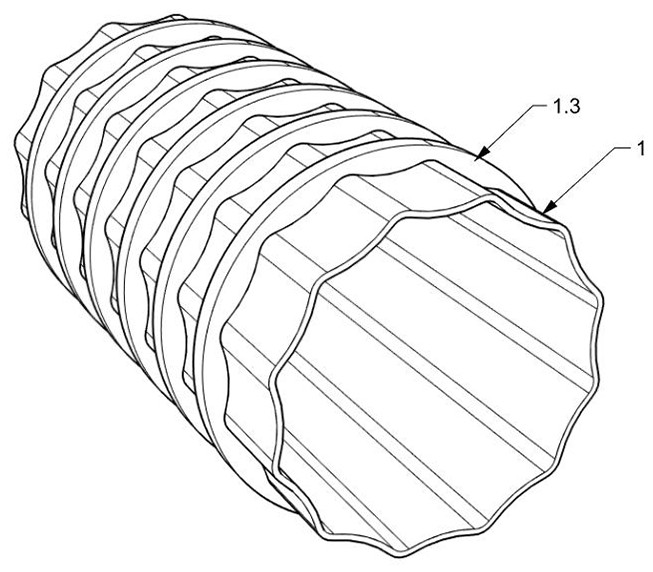

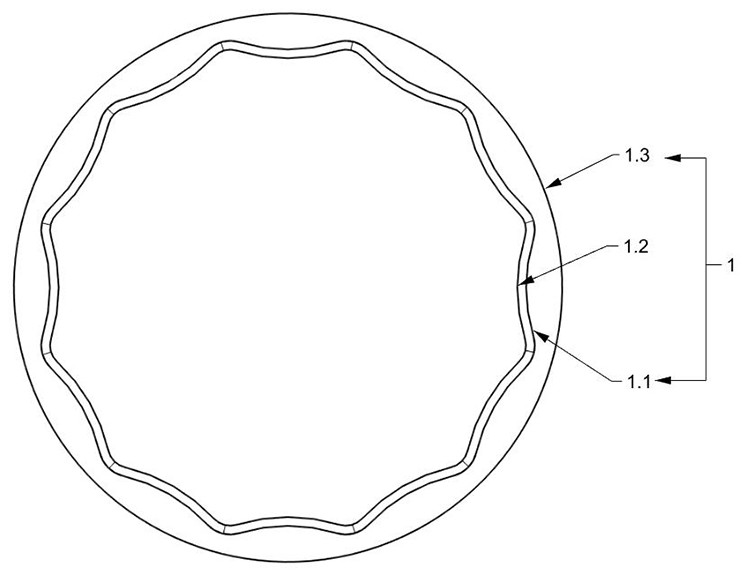

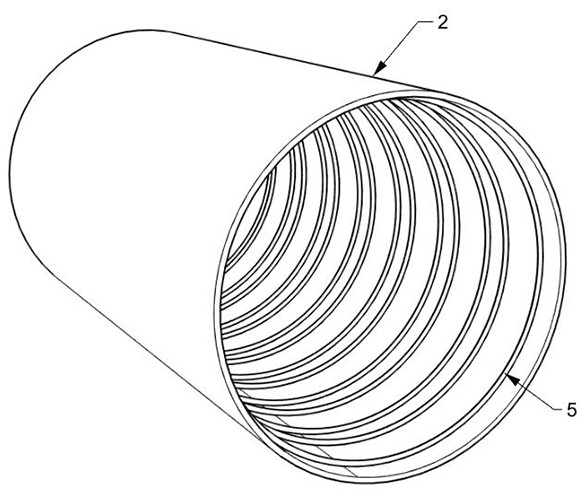

[0034] In order to make the purpose, technical solution and advantages of the application clearer, the application will be further described in detail below in conjunction with the accompanying drawings.

[0035] First of all, further explain its application scenarios: the ball mill in the prior art is a relatively mature equipment, and it can meet the requirements for crushing materials with lower particle size requirements, but for zirconia ceramics, especially colored For zirconia, the uniformity of its particle size directly determines the dyeing accuracy; the current ball mill is not unable to meet the required accuracy, but it is difficult to achieve a uniform particle size, resulting in uneven color difference after the final product is colored. For this reason, This application proposes the following solutions.

[0036] In order to clearly understand the technical solution of the present application, the technical solution provided in the present application will be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com