Six-degree-of-freedom space microgravity simulation device and control method

A technology of microgravity simulation and control method, which is applied to the simulation device of space navigation conditions, transportation and packaging, space navigation equipment, etc. It can solve the problems of insufficient control accuracy and low system robustness, and achieve the purpose of expanding the range of motion and improving The effect of control accuracy and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

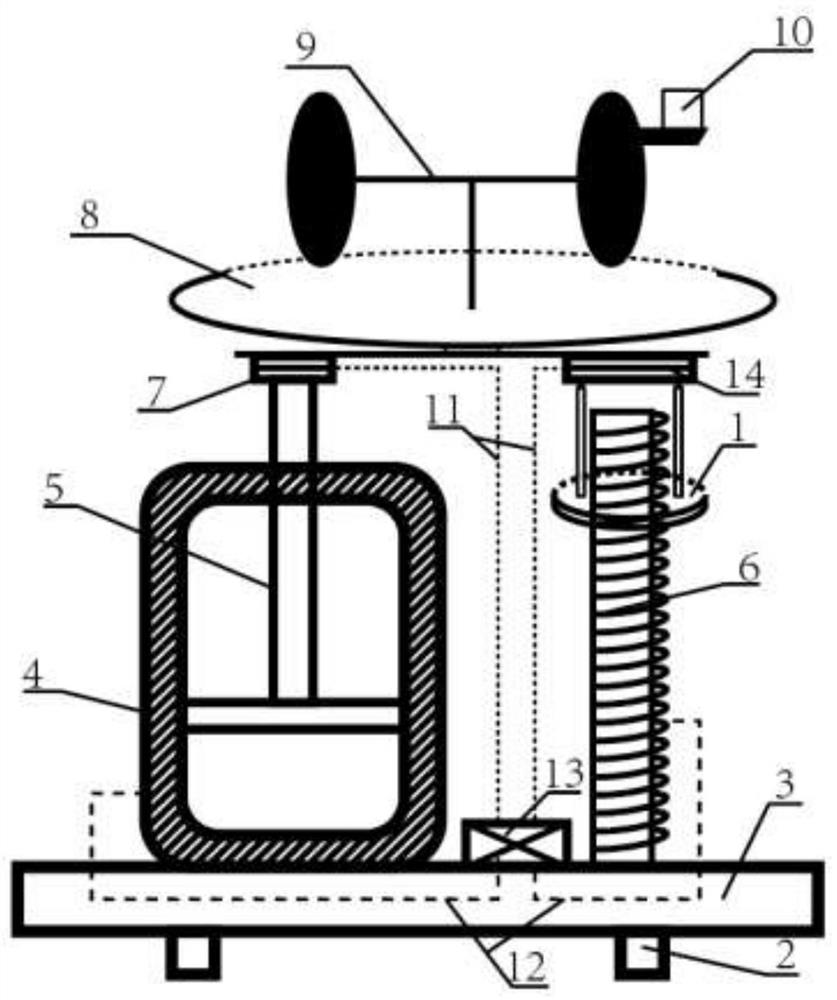

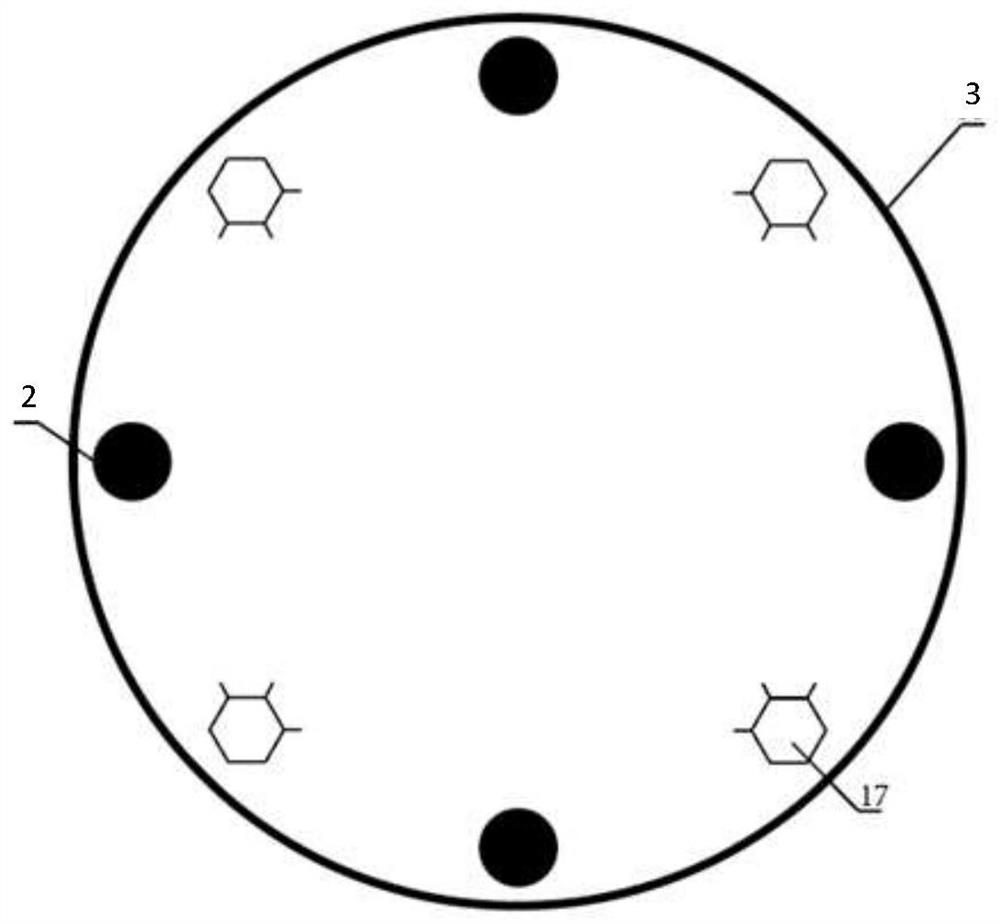

[0053] Embodiment one: if Figure 1-4 As shown in and 8, a six-degree-of-freedom space microgravity simulation device involved in this embodiment is mainly composed of a two-dimensional air bearing platform, a cylinder, a tension pressure sensor, a ball screw, a dumbbell type Composed of three-axis air bearing turntable, control module and simulated objects, such as figure 1 shown.

[0054] The simulation device is supported by four horizontal air feet to support a two-dimensional plane air-floating platform. The plane motion platform is used as a mobile base and physically serves as the lower part of the entire simulation device. The rest of the systems and subsystems are placed on this basic platform. Above, the entire simulation system is located on a horizontal plane and can float on a thin layer of air on the granite surface. Four horizontal gas square configurations are rigidly mounted on the foundation platform and powered by compressed air from four series-connected g...

Embodiment 2

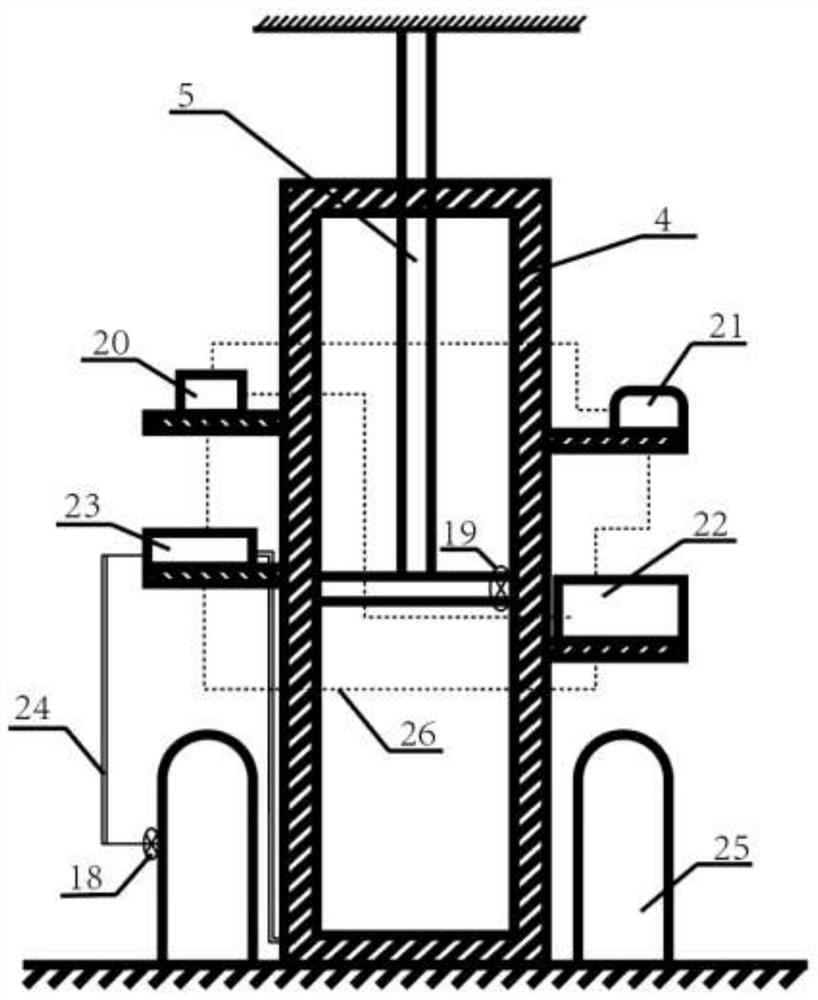

[0061] Embodiment two: if Figure 1-4 As shown, a six-degree-of-freedom space microgravity control method involved in this embodiment, the vertical direction control part:

[0062] 1. Ball screw system control

[0063] The block diagram of the closed-loop control system in the vertical direction of the system is as follows: Figure 5 As shown, the control goal of the six-DOF simulation system in the vertical direction is to make the measured value of the pressure sensor equal to the gravity value of the test target (simulated object + three-axis air-floating turntable + connection plane), and the thrust output of the low-friction cylinder Using constant value estimation, set the output thrust as the estimated value of the test target. At present, the cylinder thrust control technology is becoming more and more mature. In this system, no separate control system is designed for the cylinder thrust.

[0064] The thrust control of the ball screw adopts the terminal sliding mode ...

Embodiment 3

[0084] Embodiment 3: The control method of a six-degree-of-freedom space microgravity simulation device involved in this embodiment is the same as the microgravity simulation introduced in "Research on Multi-degree-of-Freedom Microgravity Simulation Experiment System Based on Suspension Method and Air Float Method" Compared with the device, this application uses the cross-coupling control method combining the cylinder and the ball screw, which effectively improves the microgravity simulation accuracy and dynamic response effect; avoids the gravity component in the horizontal direction brought by the suspension method, and expands the The range of motion of the microgravity simulation device and the motion posture of the simulated object; the use of neural network-based sliding mode variable structure control greatly improves the adaptability of the control system; the six-degree-of-freedom simulation is realized, which is more advanced, more reliable, more practical.

[0085] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com