Application of modified steel slag in treating printing and dyeing wastewater by activating persulfate

A technology for activating persulfate and printing and dyeing wastewater, which is applied in the direction of oxidized water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of waste of steel slag resources and difficult treatment of printing and dyeing wastewater, and achieve reduction Disposal costs, good reusability, and the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The steel slag powder with a particle size of 40 mesh was placed in a horse-boiler furnace and calcined at 500°C for 3 hours to obtain modified steel slag.

[0047] At 20°C, potassium sulfate and the obtained modified steel slag were put into the printing and dyeing wastewater containing methyl orange for shaking treatment.

[0048] Among them, the concentration of modified steel slag was 1g / L, the concentration of potassium persulfate was 1mmol / L, the oscillation speed was 100rpm, and the oscillation time was 120min.

Embodiment 2

[0050] A modified steel slag is prepared by the following method:

[0051] The steel slag powder with a particle size of 80 mesh was placed in a horse-boiler furnace and calcined at 700°C for 2 hours to obtain modified steel slag.

[0052] At 25°C, potassium sulfate and the prepared modified steel slag were added to the printing and dyeing wastewater containing methyl orange for shaking treatment.

[0053] Among them, the concentration of modified steel slag was 10g / L, the concentration of potassium persulfate was 10mmol / L, the oscillation speed was 200rpm, and the oscillation time was 180min.

Embodiment 3

[0055] A modified steel slag is prepared by the following method:

[0056] The steel slag powder with a particle size of 60 mesh was placed in a horse-boiler furnace and calcined at 800°C for 1 hour to obtain modified steel slag.

[0057] At 30°C, potassium sulfate and the prepared modified steel slag were put into the printing and dyeing wastewater containing methyl orange for shaking treatment.

[0058]Among them, the concentration of modified steel slag was 13g / L, the concentration of potassium persulfate was 15mmol / L, the oscillation speed was 300rpm, and the oscillation time was 20min.

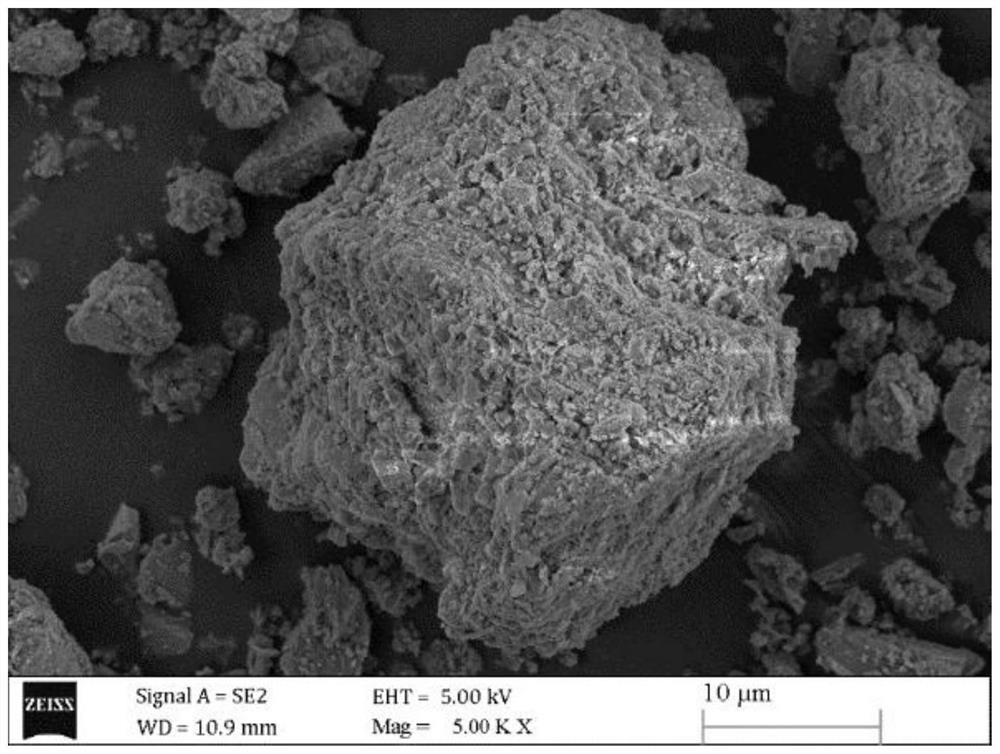

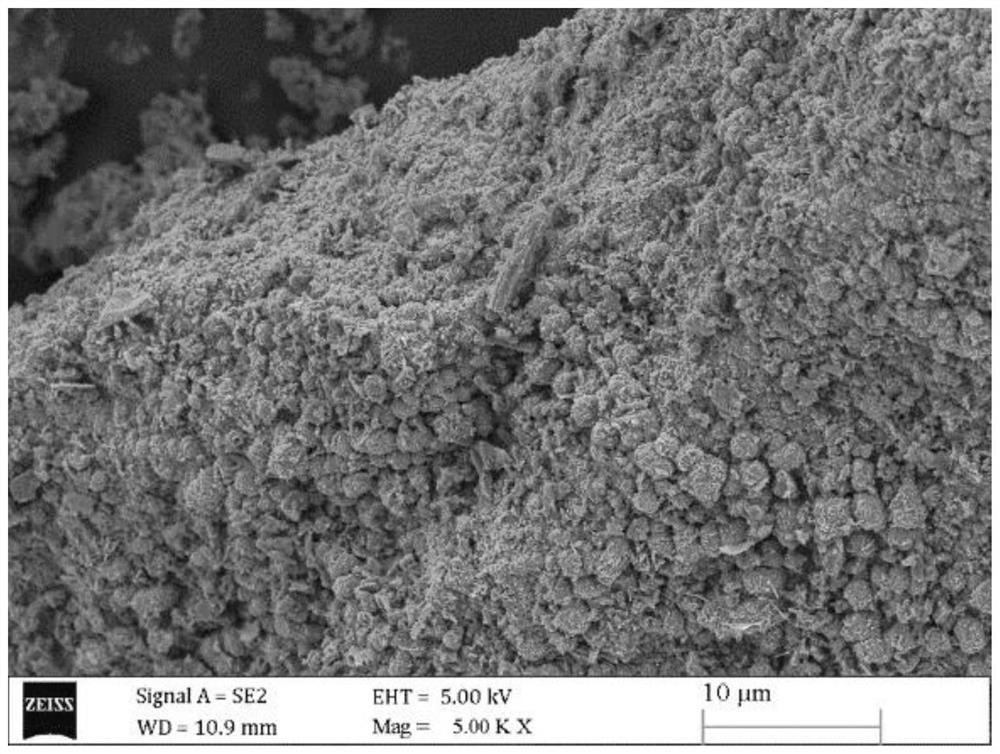

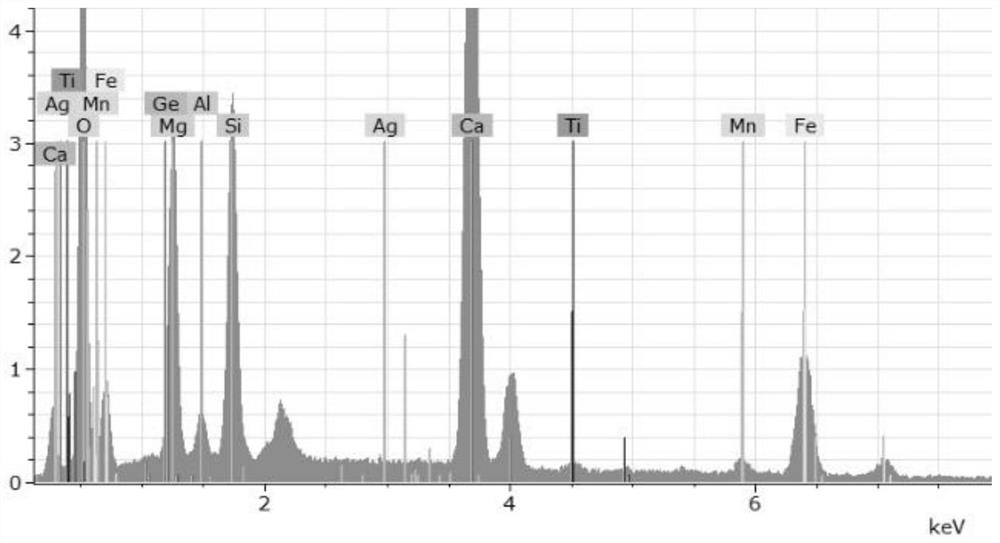

[0059] Carry out electron microscope scanning to the steel slag powder before and after modification of embodiment 2 respectively, scanning result is respectively as follows figure 1 , figure 2 shown. Untreated steel slag particles have a relatively smooth, flat surface and small size. In contrast, the surface morphology of steel slag powder changed significantly after modification a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com