Synthesis method of 2-aryl quinoline compound

A synthesis method and arylquinoline technology, applied in the direction of organic chemistry, etc., can solve the problems of low yield, poor tolerance of substrate functional groups, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

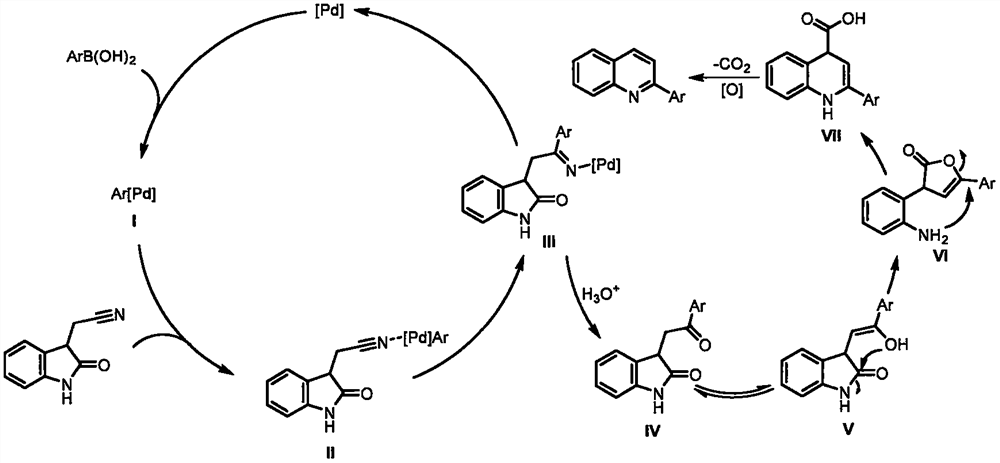

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

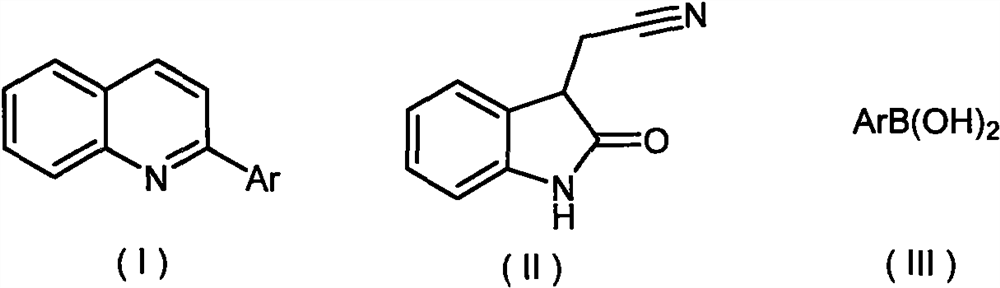

[0029] Embodiment 1: the synthesis of 2-phenylquinoline

[0030]

[0031] In a dry and clean reactor, add 15mL solvent water and 5mL solvent tetrahydrofuran, then add the above formula (II) compound, formula (III) compound, palladium acetate, bipyridine, p-toluenesulfonic acid successively, so that the molar ratio is 1 : 2: 0.05: 0.1: 8, wherein the compound of formula (II) is 3 mmol. The reaction system was stirred and reacted at 80° C. for 24 hours. After the reaction, the solvent in the reactor was removed by a rotary evaporator, and the residue was purified by column chromatography with 200-300 mesh silica gel to obtain the target product as a yellow oil with a yield of 86%.

[0032] NMR data: 1 H NMR (500MHz, CDCl 3 )δ8.22-8.18(m, 4H), 7.87(d, J=8.5Hz, 1H), 7.83(d, J=8.0Hz, 1H), 7.76-7.73(m, 1H), 7.56-7.52(m , 3H), 7.50-7.47(m, 1H); 13 C NMR (125MHz, CDCl 3)δ157.3, 148.2, 139.6, 136.7, 129.7, 129.6, 129.3, 128.8, 127.5, 127.4, 127.1, 126.2, 118.9.

Embodiment 2

[0033] Embodiment 2: the synthesis of 2-(o-tolyl) quinoline

[0034]

[0035] In a dry and clean reactor, add 15mL solvent water and 5mL solvent tetrahydrofuran, then add the above formula (II) compound, formula (III) compound, palladium acetate, bipyridine, p-toluenesulfonic acid successively, so that the molar ratio is 1 : 2: 0.06: 0.12: 8, wherein the compound of formula (II) is 3 mmol. The reaction system was stirred and reacted at 90° C. for 24 hours. After the reaction, the solvent in the reactor was removed by a rotary evaporator, and the residue was purified by column chromatography with 200-300 mesh silica gel to obtain the target product as a yellow oil with a yield of 75%.

[0036] NMR data: 1 H NMR (500MHz, CDCl 3 )δ8.23-8.18 (m, 2H), 7.87 (d, J=8.5Hz, 1H), 7.77-7.74 (m, 1H), 7.59-7.54 (m, 2H), 7.53-7.51 (m, 1H) , 2.43(s, 3H); 13 C NMR (125MHz, CDCl 3 )δ160.2, 147.8, 140.6, 136.1, 136.0, 130.8, 129.7, 129.6, 129.5, 128.5, 127.5, 126.7, 126.4, 126.0, 122.3,...

Embodiment 3

[0037] Embodiment 3: the synthesis of 2-(p-tolyl) quinoline

[0038]

[0039] In a dry and clean reactor, add 15mL solvent water and 5mL solvent tetrahydrofuran, then add the above formula (II) compound, formula (III) compound, palladium acetate, bipyridine, p-toluenesulfonic acid successively, so that the molar ratio is 1 : 2: 0.05: 0.1: 10, wherein the compound of formula (II) is 3 mmol. The reaction system was stirred and reacted at 90° C. for 24 hours. After the reaction, the solvent in the reactor was removed by a rotary evaporator, and the residue was purified by column chromatography with 200-300 mesh silica gel to obtain the target product as a yellow oil with a yield of 88%.

[0040] NMR data: 1 H NMR (400MHz, CDCl 3 )δ8.19(d, J=8.4Hz, 2H), 8.08(d, J=8.4Hz, 2H), 7.86(d, J=8.4Hz, 1H), 7.83-7.80(m, 1H), 7.75- 7.71(m, 1H), 7.54-7.50(m, 1H), 7.35(d, J=8.0Hz, 2H), 2.45(s, 3H); 13 C NMR (125MHz, CDCl 3 )δ157.3, 148.2, 139.4, 136.7, 136.7, 129.6, 129.6, 129.5, 127.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com