High-wear-resistance and high-water-contact-angle hardened film

A contact angle, hardened film technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of increased material cost and process cost, high manufacturing cost, low adhesion, etc., and achieves stable solvent-resistant wiping performance, The effect of friction stability and high water contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

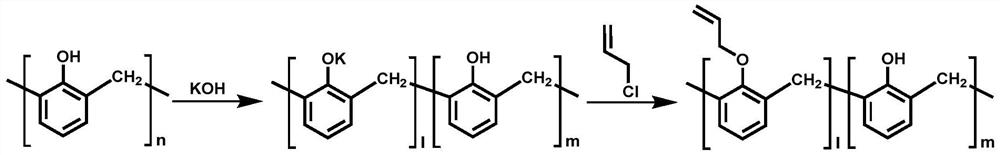

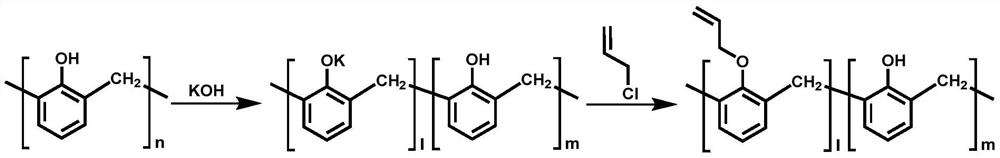

[0019] Embodiment 1: A kind of high wear-resisting high water contact angle sclerosis film, comprises the transparent base material, primer layer and AF layer that are bonded successively from bottom to top, base coat is coated on transparent base material by primer solution Photocuring is formed, and the AF layer is formed by coating the AF coating solution on the primer layer and thermosetting. The material components of the primer solution are: 38 parts by weight of polyurethane acrylate resin oligomer, 2 parts by weight of Allyl modified terminal allyl phenolic resin, 1 weight part of photoinitiator, 0.5 weight part of leveling agent and 60 weight parts of organic solvent, AF coating solution includes a solid content of 1% of the end group is Silicone modified perfluoropolyether coating solution.

[0020] Among them, the urethane acrylate resin oligomer is aliphatic urethane acrylate with 6 functionalities, and the specific choice is the resin of R0310 from Huizhixing Comp...

Embodiment 2

[0021] Embodiment 2: A kind of high wear-resisting high-water contact angle sclerosis film, comprises the transparent base material, primer layer and AF layer that are laminated successively from bottom to top, and base coat is coated on transparent base material by primer liquid Photocuring is formed, and the AF layer is formed by coating the AF coating solution on the primer layer and thermosetting. The material components of the primer solution are: 42 parts by weight of polyurethane acrylate resin oligomer, 5 parts by weight of Allyl modified terminal allyl phenolic resin, 1.5 parts by weight of photoinitiator, 0.7 parts by weight of leveling agent and 43 parts by weight of organic solvent, the AF coating solution includes a solid content of 1% of the end group is Silicone modified perfluoropolyether coating solution.

[0022] Among them, the urethane acrylate resin oligomer is aliphatic urethane acrylate with 6 functionalities, and the specific choice is the resin of R031...

Embodiment 3

[0023] Embodiment 3: A kind of high wear-resistant high-water contact angle sclerosis film, comprises the transparent base material, base coat and AF layer that are bonded successively from bottom to top, and base coat is coated on transparent base material by primer liquid Photocuring is formed, and the AF layer is formed by coating the AF coating solution on the primer layer and thermosetting. The material components of the primer solution are: 40 parts by weight of polyurethane acrylate resin oligomer, 20 parts by weight of Allyl modified terminal allyl phenolic resin, 2 weight parts photoinitiator, 0.9 weight parts leveling agent and 48 weight parts organic solvents, AF coating solution includes solid content of 1% end group is Silicone modified perfluoropolyether coating solution.

[0024]Among them, the urethane acrylate resin oligomer is aliphatic urethane acrylate with 6 functionalities, and the specific choice is the resin of R0310 from Huizhixing Company; the termina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com