Preparation method of natural mineral-based super-hydrophobic coating and oil-water separation net

An oil-water separation net, natural mineral technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of high cost, complicated preparation process, inability to large-scale preparation, etc., and achieve good self-cleaning performance and operation technology. Simple, cycle-stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

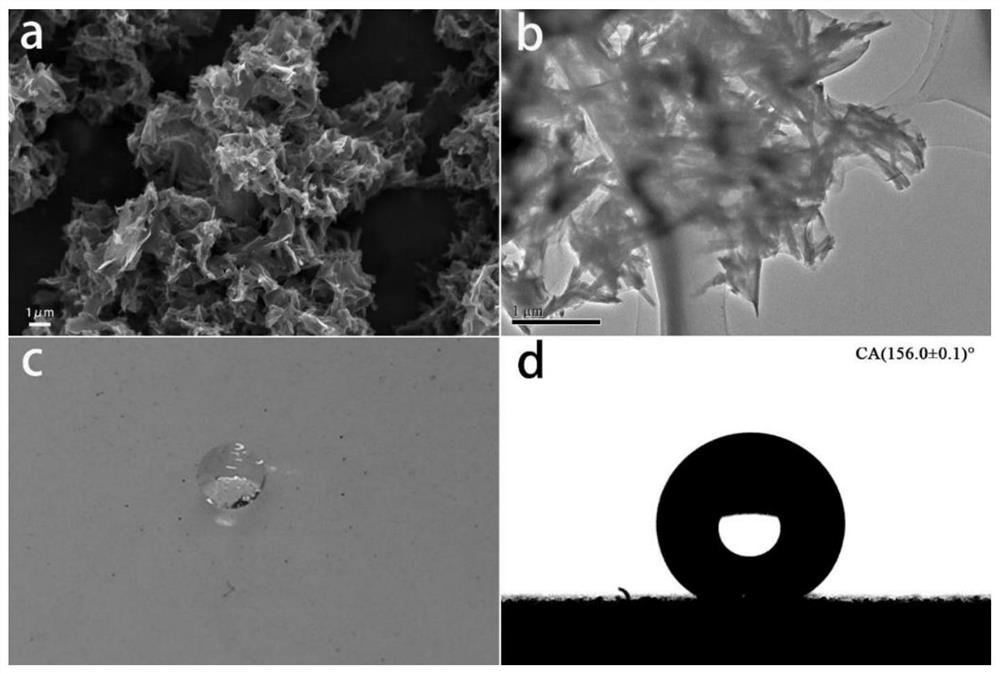

[0021] Embodiment 1: (1) base material pretreatment: the glass base material is cut into required size (5-10cm), the glass sheet cleaned with ethanol ultrasonic cleaning 30min is dried standby; (2) superhydrophobic suspension Preparation: ultrasonically disperse 1 part by weight of halloysite in 79 parts by weight of absolute ethanol and 18.2 parts by weight of ammonia water, add 1.1 parts by weight of hexadecyltrimethoxysilane under 500 r / min magnetic stirring, and then The reaction was continuously stirred for 2 hours, centrifuged at a speed of 6000 r / min for 5 minutes, and the centrifuged precipitate was collected and ultrasonically dispersed in 15.8 parts by weight of absolute ethanol. (3) Preparation of superhydrophobic coating: Spray the prepared superhydrophobic suspension onto a glass sheet, set the spraying pressure to 0.2 MPa, spraying distance to 10 cm, and dry at 60° C. for 5 hours.

Embodiment 2

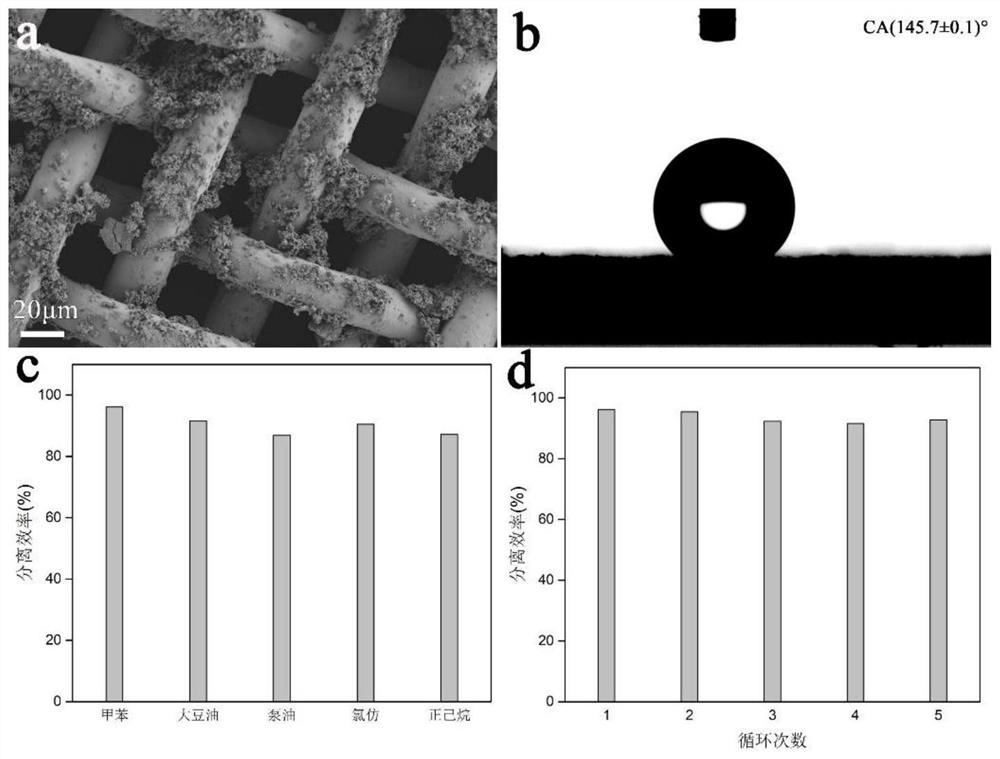

[0022] Embodiment 2: (1) substrate material pretreatment: the stainless steel mesh substrate material is cut into required size (5-10cm), the cleaned stainless steel mesh is ultrasonically cleaned with ethanol for 30min and then dried for later use; (2) superhydrophobic suspension Preparation: ultrasonically disperse 1 part by weight of halloysite in 79 parts by weight of absolute ethanol and 18.2 parts by weight of ammonia water, add 1.1 parts by weight of hexadecyltrimethoxysilane under magnetic stirring at 500 r / min, and then Stirring was continued for 2 hours under the conditions, centrifuged at 6000 r / min for 5 minutes, the precipitate after centrifugation was collected, and ultrasonically dispersed in 15.8 parts by weight of absolute ethanol. (3) Preparation of oil-water separation net: Spray the prepared superhydrophobic suspension onto the stainless steel net, set the spraying pressure to 0.2 MPa, spraying distance to 10 cm, and dry at 60° C. for 5 h.

Embodiment 3

[0023] Embodiment 3: (1) base material pretreatment: the fabric / wood / carbon steel sheet base material is cut into required size (5-10cm), after the cleaned fabric / wood / carbon steel sheet is ultrasonically cleaned with ethanol for 30min (2) Preparation of superhydrophobic suspension: ultrasonically disperse 1 part by weight of halloysite in 79 parts by weight of absolute ethanol and 18.2 parts by weight of ammonia water, under magnetic stirring at 500r / min, add 1.1 parts by weight of ten Hexaalkyltrimethoxysilane was stirred and reacted at room temperature for 2 hours, centrifuged at 6000 r / min for 5 minutes, and the precipitate after centrifugation was collected and ultrasonically dispersed in 15.8 parts by weight of absolute ethanol. (3) Preparation of superhydrophobic coating: Spray the prepared superhydrophobic suspension onto fabric / wood / carbon steel sheet, set the spraying pressure to 0.2MPa, spraying distance is 10 cm, and dry at 60°C 5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com