Polyimide/inorganic material composite aerogel thermal insulation layer for smoking set

A technology of composite aerogel and polyimide, which is applied in the field of thermal insulation layer of smoking utensils, can solve the problems of impossible industrialized preparation, high graphene price and high cost, and achieve stable product shape, complex process and economical cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

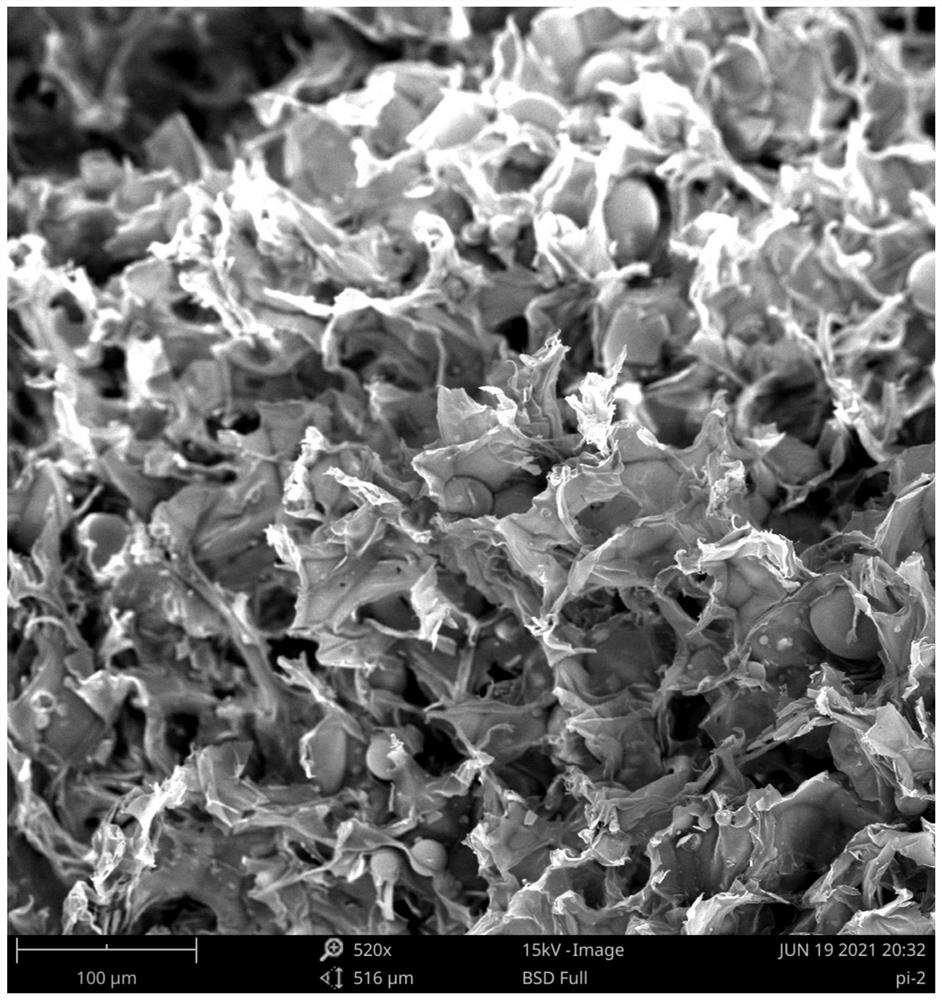

Image

Examples

Embodiment 1

[0034] (1) Disperse 30g of hollow glass microspheres in 120g of NMP, stir at a high speed for 5min to obtain a uniformly dispersed suspension A; slowly pour 3g of ungelled polyimide organic solution B into the uniformly dispersed suspension A, Stir for 1 h to fully mix the two to obtain colloidal solution C;

[0035] (2) Pour the colloidal solution C into the mold, and let stand at 30°C for 24 hours to solidify the gel;

[0036] (3) Demoulding, immersing the wet gel in acetone, and replacing the solvent 3 times, each time for 24 hours, to obtain a semi-finished product;

[0037] (4) Dry the semi-finished product in an oven for 12 hours to obtain a sleeve-type composite airgel heat insulation layer.

Embodiment 2

[0039] (1) Disperse 50g of hollow glass microspheres in 180g of NMP, stir at a high speed for 5min to obtain a uniformly dispersed suspension A; slowly pour 6g of ungelled polyimide organic solution B into the uniformly dispersed suspension A, Stir for 1 h to fully mix the two to obtain colloidal solution C;

[0040] (2) Pour the colloidal solution C into the mold, and let stand at 30°C for 24 hours to solidify the gel;

[0041] (3) Demoulding, immersing the wet gel in ethanol, replacing the solvent 3 times, each time for 24 hours, to obtain a semi-finished product;

[0042] (4) Dry the semi-finished product in an oven for 12 hours to obtain a sleeve-type composite airgel heat insulation layer.

Embodiment 3

[0044] (1) Disperse 30 g of porous ceramic microbeads in 150 g of NMP, stir at high speed for 5 min to obtain a uniformly dispersed suspension A; slowly pour 10 g of ungelled polyimide organic solution B into the uniformly dispersed suspension A, Stir for 1 h to fully mix the two to obtain colloidal solution C;

[0045] (2) Pour the colloidal solution C into the mold, and let stand at 30°C for 24 hours to solidify the gel;

[0046] (3) Demoulding, immersing the wet gel in acetone, and replacing the solvent 3 times, each time for 24 hours, to obtain a semi-finished product;

[0047] (4) Dry the semi-finished product in an oven for 12 hours to obtain a sleeve-type composite airgel heat insulation layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com