Gas sensitive sensor for detecting acetone and application thereof

A gas sensor, acetone technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as complex sensor manufacturing technology, and achieve significant response and reversibility, easy post-processing, and fast response and recovery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

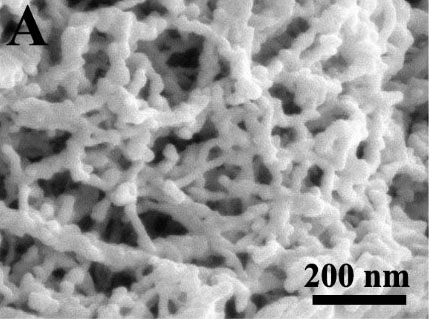

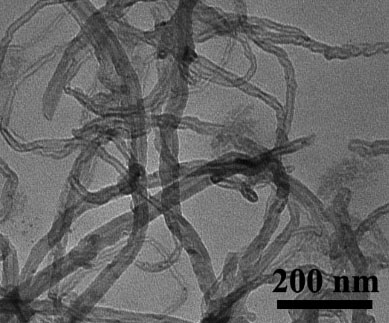

[0042] (1) Disperse 40 mg of multi-walled carbon nanotubes in 4 mL of N,N-dimethylformamide and ultrasonically disperse them evenly, then add 1 mg / mL of tetraaminophenylnickel porphyrin solution to the above system In, let stand for 24h.

[0043] (2) The product is completely separated by centrifugation, and then the crude product is washed with N,N-dimethylformamide until it is colorless, and the multi-walled carbon nanotube product functionalized with tetraaminophenylnickel porphyrin is collected and dried .

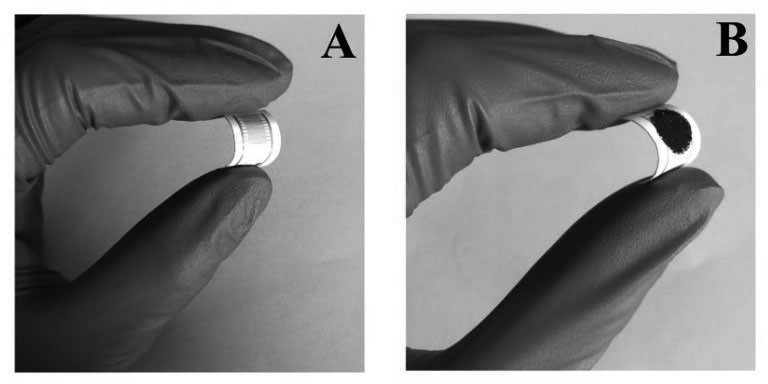

[0044] (3) A printed electrode consisting of 10 pairs of interdigitated electrodes was deposited on the paper substrate by spraying gold, and then 5 mg / mL tetraaminophenylnickel porphyrin-functionalized multi-walled carbon nanotube suspension was carefully dropped on the On the printed electrode, the solvent is completely evaporated to obtain a gas sensor.

Embodiment 2

[0046] (1) Disperse 25mg of multi-walled carbon nanotubes in 2.5mL of N,N-dimethylformamide and ultrasonically disperse them evenly, then add 0.63mg / mL of tetraaminophenylnickel porphyrin solution into In the above system, let stand for 15 hours.

[0047] (2) The product is completely separated by centrifugation, and then the crude product is washed with N,N-dimethylformamide until it is colorless, and the multi-walled carbon nanotube product functionalized with tetraaminophenylnickel porphyrin is collected and dried .

[0048] (3) The printed electrode consisting of 7 pairs of interdigitated electrodes was deposited on the paper substrate by spraying gold, and then 3 mg / mL tetraaminophenylnickel porphyrin-functionalized multi-walled carbon nanotube suspension was carefully dropped on the On the printed electrode, the solvent was completely evaporated to obtain the same gas sensor as in Example 1.

Embodiment 3

[0050] (1) Disperse 50 mg of multi-walled carbon nanotubes in 5 mL of N,N-dimethylformamide and ultrasonically disperse them evenly, then add 1.25 mg / mL of tetraaminophenylnickel porphyrin solution to the above In the system, let it stand for 30h.

[0051] (2) The product is completely separated by centrifugation, and then the crude product is washed with N,N-dimethylformamide until it is colorless, and the multi-walled carbon nanotube product functionalized with tetraaminophenylnickel porphyrin is collected and dried .

[0052] (3) The printed electrode consisting of 13 pairs of interdigitated electrodes was deposited on the paper substrate by spraying gold, and then 6.25 mg / mL tetraaminophenylnickel porphyrin functionalized multi-walled carbon nanotube suspension was carefully dropped On the printed electrodes, the solvent was completely evaporated to obtain the same gas sensor as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Overlap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com