Manufacturing process of conductive heating anti-fog glasses

A manufacturing process and a conductive technology, which is applied in the field of manufacturing process of conductive heating anti-fog glasses, can solve the problems of insufficient practicability and poor anti-fog performance, and achieve the effect of durable anti-fog function and strong heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples, whereby the application of how to apply techniques to solve technical problems and achieve technical efficacy.

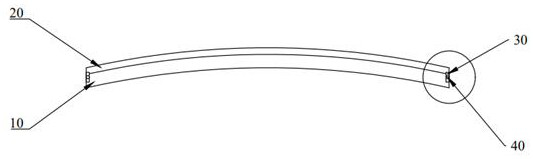

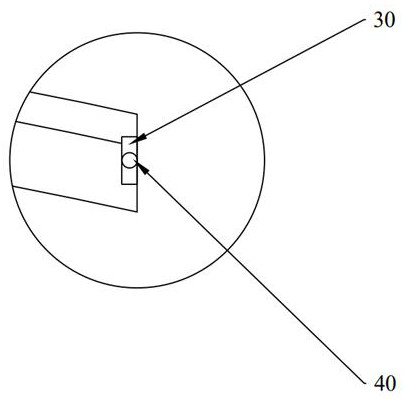

[0024] Please refer to figure 1 and figure 2 , figure 1 It is a schematic view of the resin substrate of the embodiment of the present invention; figure 2 Yes figure 1 Local enlargement.

[0025] As shown, a manufacturing process of electrically conductive heating anti-fog glasses includes:

[0026] Step a. Provide a solid resin substrate 10 for cleaning;

[0027] Step b. The sputtering of the highly conductive non-metal oxide and the metal oxide melted by vacuum ion sputtering, and the sputtering is attached to the surface of the resin substrate 10, forming a high conductive film layer 20;

[0028] Step c. Phase the resin substrate 10 and grind the resin substrate 10 by cherishing, and then coarse milling, fine milling, polishing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com