Method for controlling direct-writing photoetching machine and direct-writing photoetching machine

A lithography machine and direct-write technology, applied in the field of data processing, can solve the problems of slow processing speed, long processing time, and inability to use data effectively, so as to shorten the processing time and improve the processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

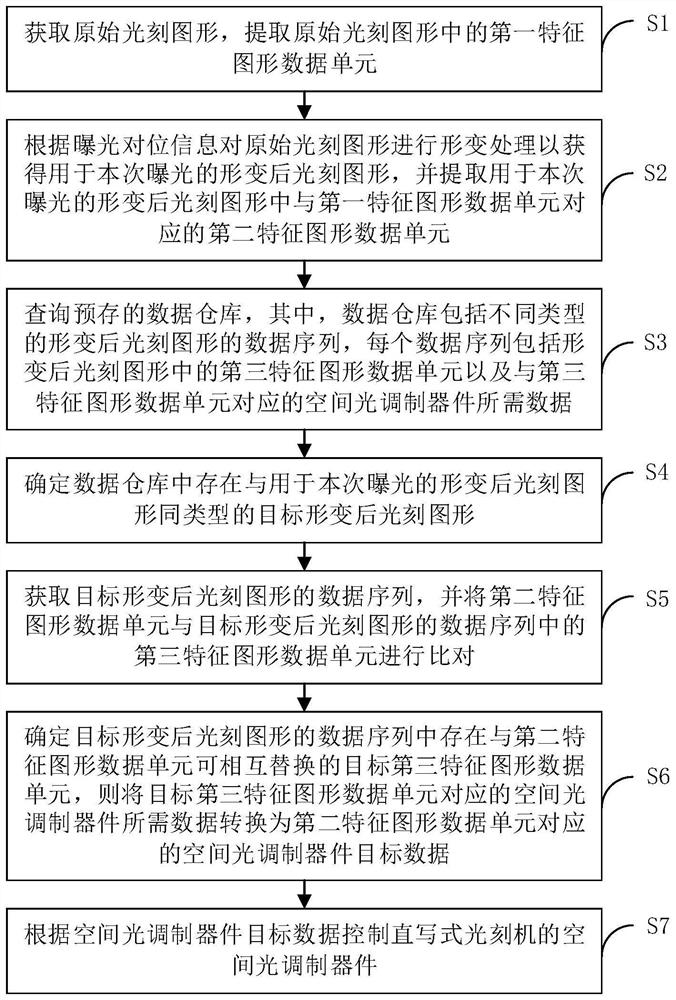

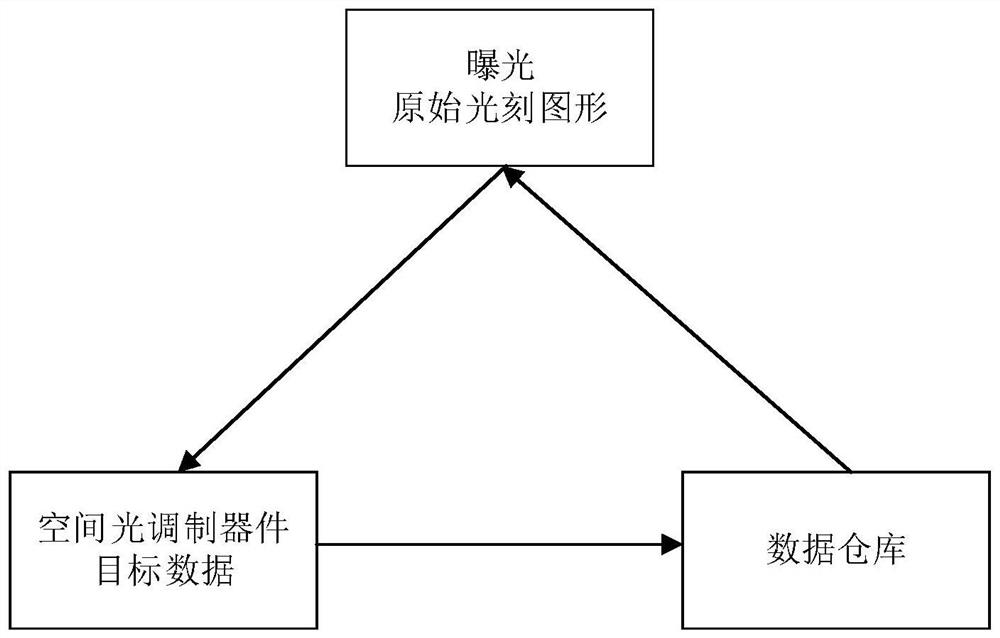

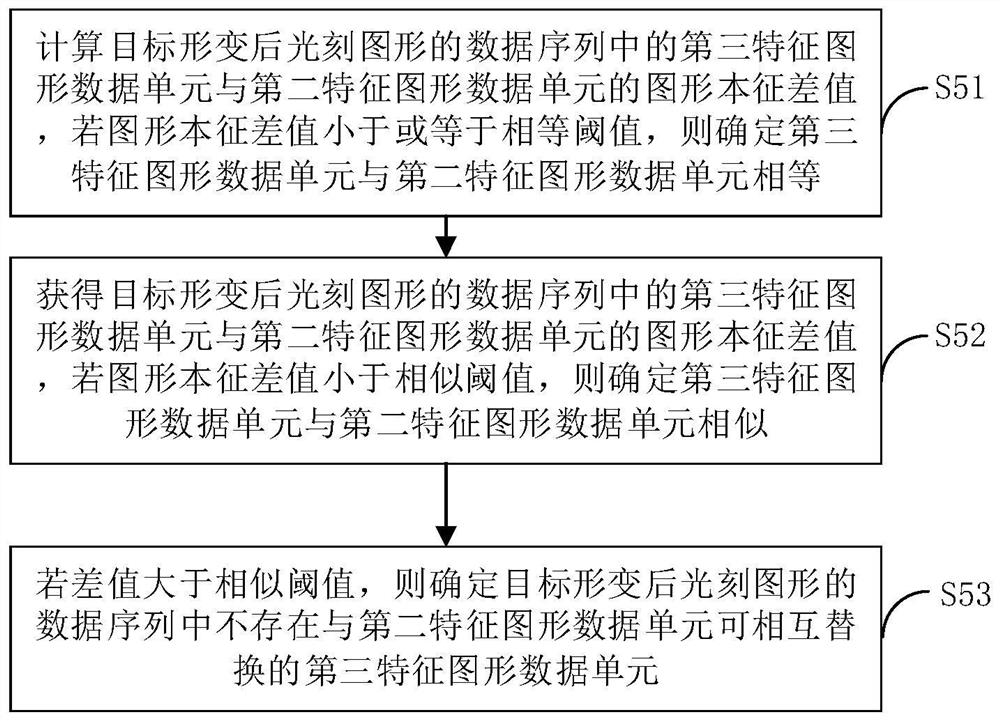

[0034] Refer below figure 1 - Figure 4 A method of controlling a direct write photolithography machine according to an embodiment of the present invention is described.

[0035] In some embodiments of the present invention, the direct writing lithography machine includes a spatial light modulation device, wherein the spatial light modulation device can use a DMD (Digital Micromirror Device, digital micromirror device) device or an LCLV (Liquid Crystal Light Valve, liquid crystal light Valve) or other suitable digital optical spatial light modulators for realizing the modulation of light.

[0036] Such as figure 1 Shown is a flow chart of a method for controlling a direct-write lithography machine according to an embodiment of the present invention. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com