Method for promoting lentinus edodes flavor substance release by using ultrahigh pressure wall breaking technology

A flavor substance and ultra-high pressure technology, which is applied in the field of food processing, can solve the problems of low utilization rate of raw materials of shiitake mushroom heat reaction flavor and influence on product flavor, and achieve the effects of improving flavor, activity retention, and increasing added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

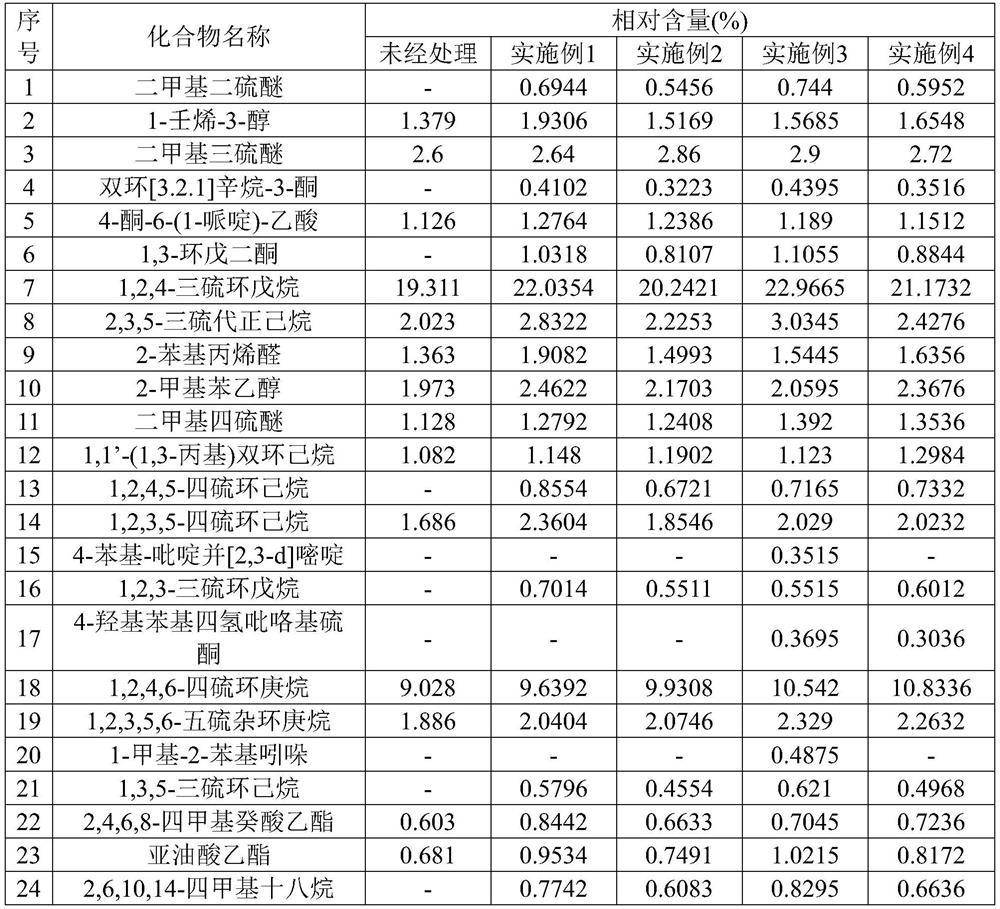

Examples

Embodiment 1

[0026] This embodiment utilizes an ultrahigh pressure technology for the specific operation broken mushroom flavor is released:

[0027] (1) The clean mushrooms placed in an oven dried, drying 48h at 50 ℃, mushrooms dried to constant weight; then, after drying the mushrooms into a high-speed mill, and grinding 3min, 80 mesh sieve, mushroom powder is obtained.

[0028] (2) to take a first layer disposed 5L mushroom powder bag and the first layer of mushroom powder containing bag opening is placed to the bottom of the second layer of the packaging bag; of mushroom powder after vacuum treatment of secondary packaging .

[0029] (3) After the vacuum treatment mushroom powder pressing cavity disposed directly integrated pressure treatment apparatus; water injected into the cavity, the cavity of the water had completely no mushroom powder; plunger will fall into place the chamber pressure was raised to 400MPa; and maintained at a pressure of 400MPa 4min conditions, dwell temperature of ...

Embodiment 2

[0031] This embodiment utilizes an ultrahigh pressure technology for the specific operation broken mushroom flavor is released:

[0032] (1) The clean mushrooms placed in an oven dried, drying 48h at 50 ℃, mushrooms dried to constant weight; then, after drying the mushrooms into a high-speed mill, and grinding 3min, 80 mesh sieve, mushroom powder is obtained.

[0033] (2) to take a first layer disposed 5L mushroom powder bag and the first layer of mushroom powder containing bag opening is placed to the bottom of the second layer of the packaging bag; of mushroom powder after vacuum treatment of secondary packaging .

[0034] (3) After the vacuum treatment mushroom powder pressing cavity disposed directly integrated pressure treatment apparatus; water injected into the cavity, the cavity of the water had completely no mushroom powder; plunger will fall into place the chamber pressure was raised to 600MPa; and maintained at a pressure of 600MPa conditions 1min, dwell temperature of ...

Embodiment 3

[0036] This embodiment utilizes an ultrahigh pressure technology for the specific operation broken mushroom flavor is released:

[0037] (1) The clean mushrooms placed in an oven dried, drying 36h at 55 ℃, mushrooms dried to constant weight; then, after drying the mushrooms into a high-speed mill, and grinding 5min, through a 100 mesh sieve to obtain a mushroom powder.

[0038] (2) to take a first layer disposed 5L mushroom powder bag and the first layer of mushroom powder containing bag opening is placed to the bottom of the second layer of the packaging bag; of mushroom powder after vacuum treatment of secondary packaging .

[0039] (3) After the vacuum treatment mushroom powder pressing cavity disposed directly integrated pressure treatment apparatus; water injected into the cavity, the cavity of the water had completely no mushroom powder; plunger will fall into place the chamber pressure was raised to 400MPa; and maintained at a pressure of 400MPa 4min conditions, dwell tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com