Underwater grinding and dust removing robot

A robot and grinding mechanism technology, applied in the field of robotics, can solve problems such as production efficiency and product quality cannot be guaranteed, manual grinding tasks have high work intensity, and the grinding environment is harsh, so as to save labor costs, protect the water environment, and reduce rework rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

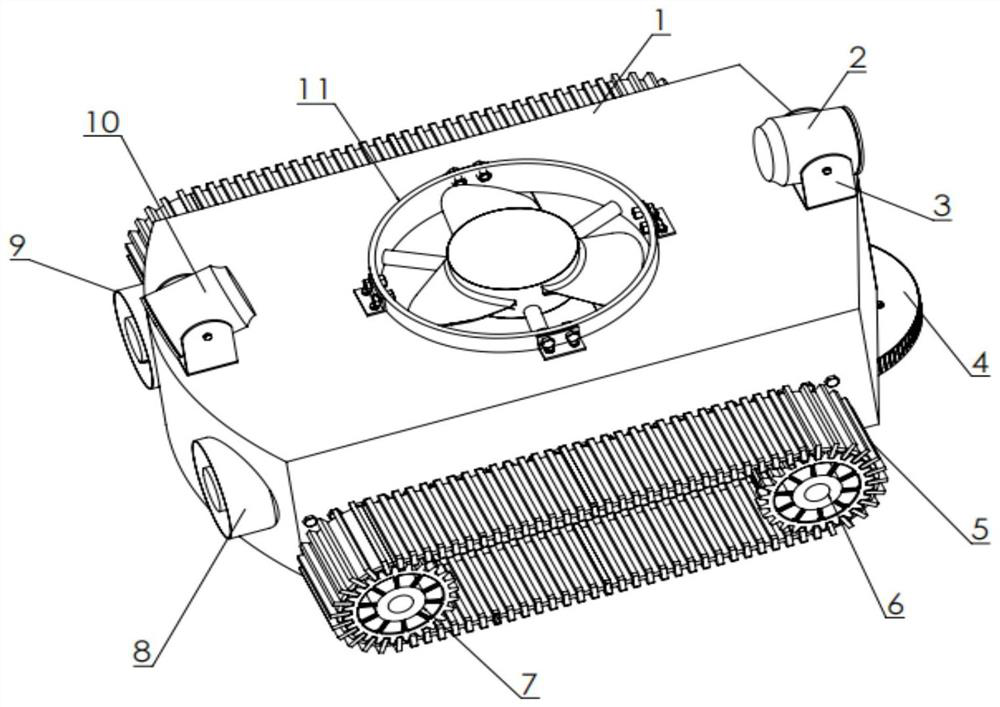

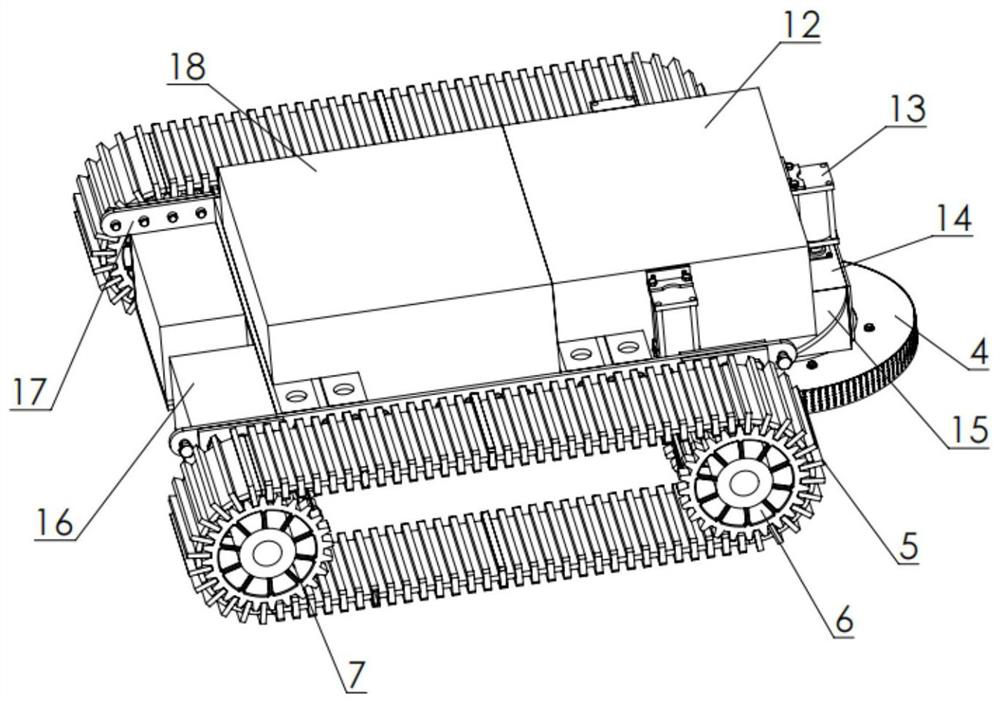

[0059] Such as Figure 1-9 As shown, the embodiment of the present invention provides an underwater grinding and dust removal robot, including a robot shell 1, a chassis 17, a driving mechanism, an adsorption mechanism, a grinding lifting mechanism, a grinding mechanism 4, a dust suction mechanism, a monitoring system and a control system.

[0060] Specifically, the front end of the robot shell 1 is "V" shaped, and the rear end is "U" shaped, and is connected to the chassis 17 by bolts.

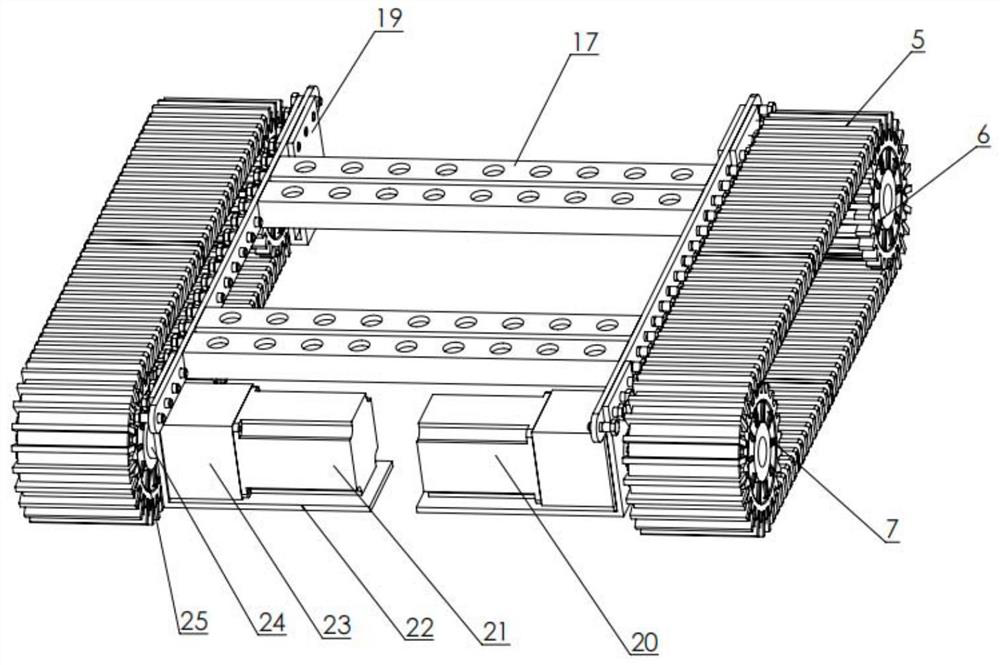

[0061] Specifically, the drive mechanism includes crawler belt 5, driving wheel one 7, driving wheel two 25, driven wheel 6, motor one 20, motor two 21, reduction box 23, coupling one 24, sealing box one 14, sealing box Base 22 and connecting plate 19; Motor one 20 connects reduction box 23, and reduction box 23 connects drive wheel one 20 of crawler belt 5 by coupling one 24, and motor two 21 connects reduction box 23, and reduction box 23 passes coupling one 24 Connect the drive wheel two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com