Compound ultralow interfacial tension surfactant and preparation method thereof

A surfactant and interfacial tension technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve good compatibility, fast dissolution, and strong anti-mineralization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

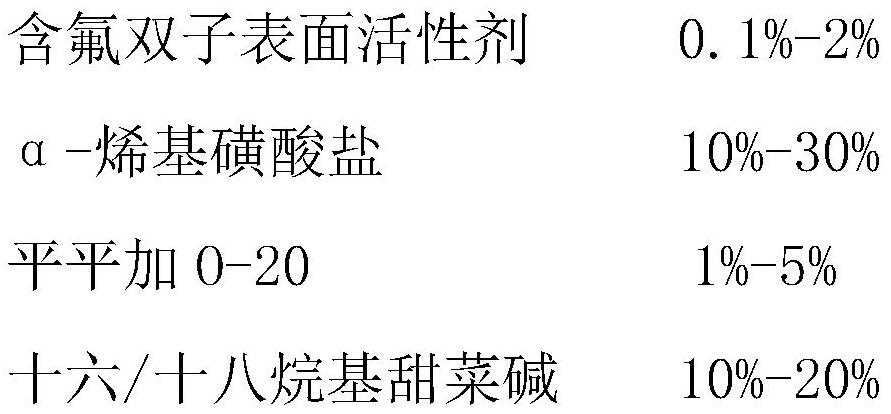

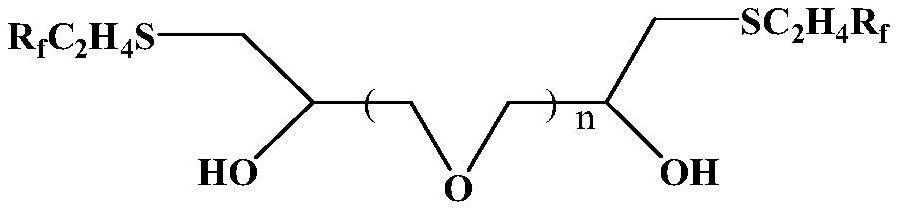

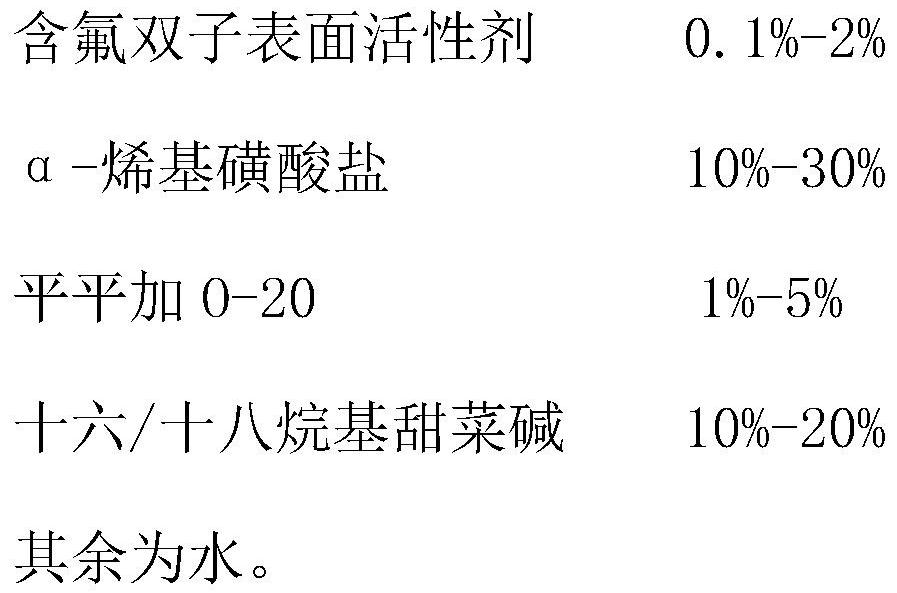

Method used

Image

Examples

Embodiment 1

[0030] First, add 72Kg of water into the reaction kettle, raise the temperature to 50°C, turn on the stirring, keep the stirring speed at 100-200rpm, add 15kg of α-alkenyl sulfonate, 1kg of Pingpingjia O-20, 6kg of cetyl di Methyl hydroxypropyl sultaine and 6kg of octadecyl dimethyl hydroxypropyl sultaine were stirred uniformly and then cooled to 30°C to obtain an ultra-low interfacial tension surfactant.

Embodiment 2

[0032] First, add 71.8Kg of water into the reactor, raise the temperature to 50°C, turn on the stirring, keep the stirring speed at 100-200rpm, add 0.2kg of fluorine-containing gemini surfactant, 15kg of α-alkenyl sulfonate, 1kg of O-20, 6kg cetyl dimethyl hydroxypropyl sulfobetaine and 6kg octadecyl dimethyl hydroxypropyl sulfobetaine, stir evenly and cool down to 30°C to obtain ultra-low interfacial tension Surfactant.

Embodiment 3

[0034] First, add 68.8Kg of water into the reactor, raise the temperature to 50°C, turn on the stirring, keep the stirring speed at 100-200rpm, add 0.2kg of fluorine-containing gemini surfactant, 20kg of α-alkenyl sulfonate, 3kg of O-20, 1kg cetyl dimethyl hydroxypropyl sultaine and 7kg octadecyl dimethyl hydroxypropyl sultaine, stir evenly and cool down to 30°C to obtain ultra-low interfacial tension surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com