High-temperature-oxidation-resistant stainless steel pipe and preparation method thereof

A technology for anti-high temperature oxidation and stainless steel pipes, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of unfavorable use, easy collapse of stainless steel pipes, low high temperature resistance and corrosion resistance, etc., to achieve convenient operation and improve the scope of application , easy to stack the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

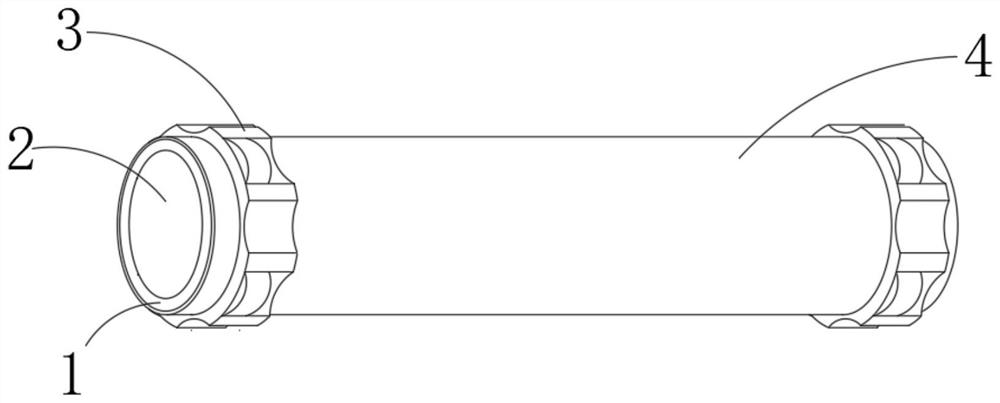

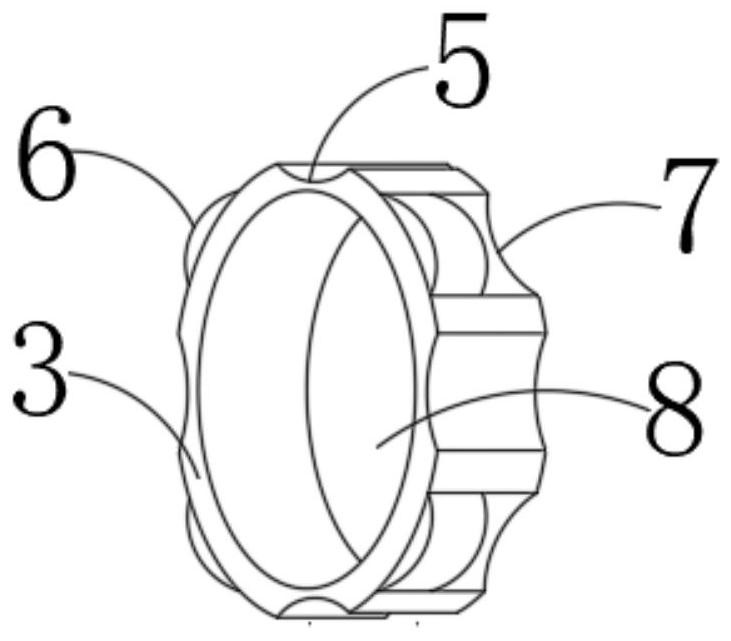

[0030] like Figure 1-3 As shown in a stainless steel tube and high temperature oxidation method of preparing an anti-, comprising a tubular body, an inner tube 2 defines a lumen, the outer tube 1 is fixedly connected with an adhesive layer 11 II, the tubular body 1 fixedly connected at both ends of the clasp body anti-roll 3, the outer adhesive layer 11 II fixedly connected with a coating 10, outer coating 10 is fixedly connected with an adhesive layer 9 One.

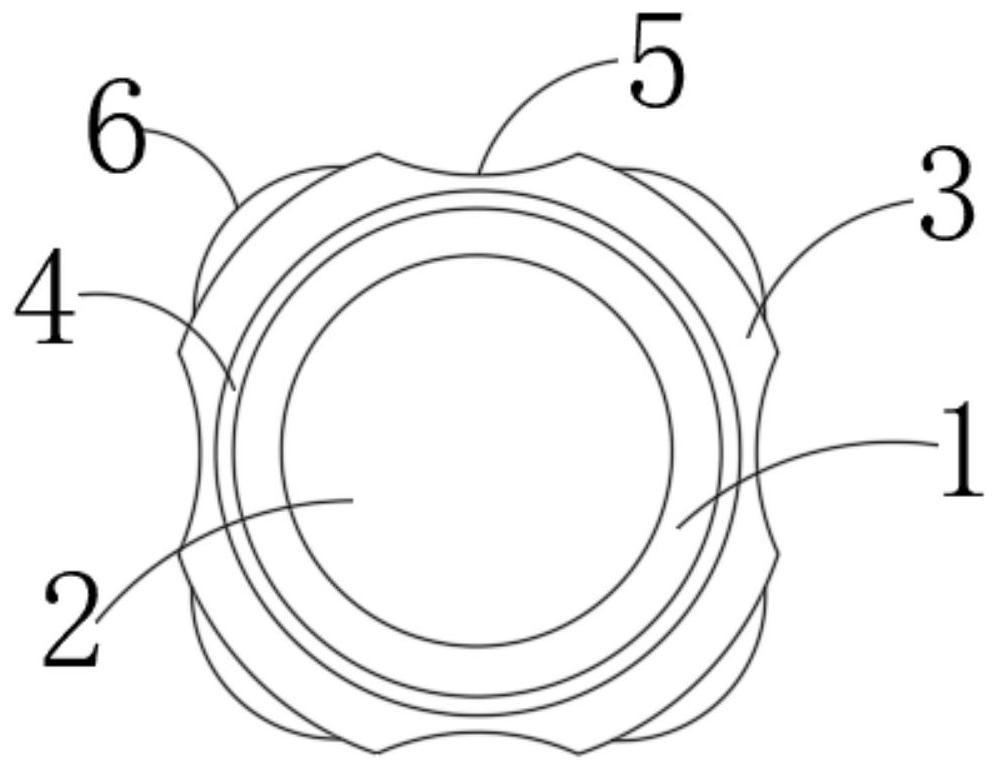

[0031] One outer adhesive layer 9 is fixedly connected with a refractory layer 4, four weeks anti-roll body 3 of the collar defines a four slot 5, slot 5 side is fixedly connected with one side of the bumps 6 bump 6 7 defines a catching groove, the inner ring card anti-roll body 3 defines a mouth ring 8.

[0032] Slot 5 evenly distributed on the outside of the collar anti-roll body 3, two bumps 6 is located inside the slot 5, the width of the groove 7 and buckle quite bumps 6.

[0033] 4 through the inner refractory layer O...

Embodiment 2

[0036] like figure 1 , 2 4, the stainless steel tube and a high-temperature oxidation method of preparing an anti-, comprising a tubular body, an inner tube 2 defines a lumen, the outer tube 1 is fixedly connected with an adhesive layer 11 II, tubes 1 is fixedly connected at both ends with a collar anti-roll body 3, the outer adhesive layer 11 II fixedly connected with a coating 10, outer coating 10 is fixedly connected with an adhesive layer 9 One.

[0037]One outer adhesive layer 9 is fixedly connected with a refractory layer 4, four weeks anti-roll body 3 of the collar defines a four slot 5, slot 5 side is fixedly connected with one side of the bumps 6 bump 6 7 defines a catching groove, the inner ring card anti-roll body 3 defines a mouth ring 8.

[0038] Slot 5 evenly distributed on the outside of the collar anti-roll body 3, two bumps 6 is located inside the slot 5, the width of the groove 7 and buckle quite bumps 6.

[0039] Anti-roll card body inner ring 3 is slidably conn...

Embodiment 3

[0042] A process for preparing high temperature oxidation resistant stainless steel pipe, comprising the steps of:

[0043] S1: First, raw materials of the rolled strip annealing, the workpiece is heated to a predetermined temperature, a certain time after incubation slowly cooled metal heat treatment process, annealing in order to: eliminate or improve the steel in casting, forging, rolling and welding process in a variety of tissue defects caused by the residual stress and to prevent deformation of the workpiece, cracking, softening of the workpiece for machining, to improve the grain refinement tissue to improve the mechanical properties of the workpiece, ready for the final heat treatment and tissue preparation pipe;

[0044] S2: dividing strip and the points of welding, the stainless steel coil is a stainless steel coil, cut to the appropriate width so for further processing and pipe, striping process is noted slitting knife scratching of COIL , stripe width and error, relate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com