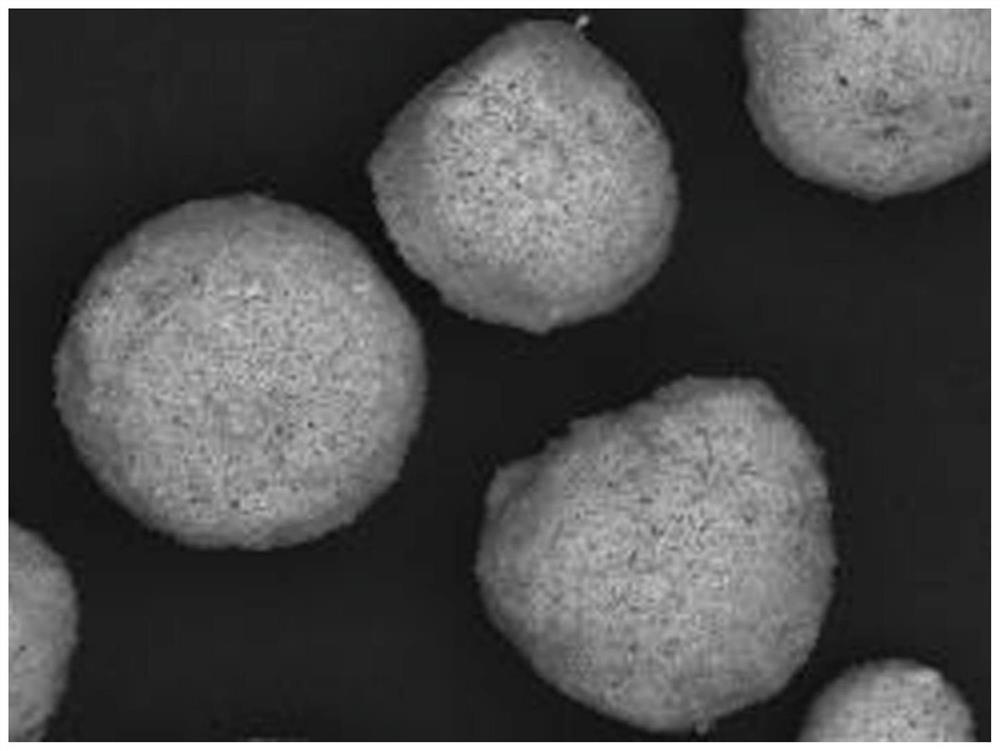

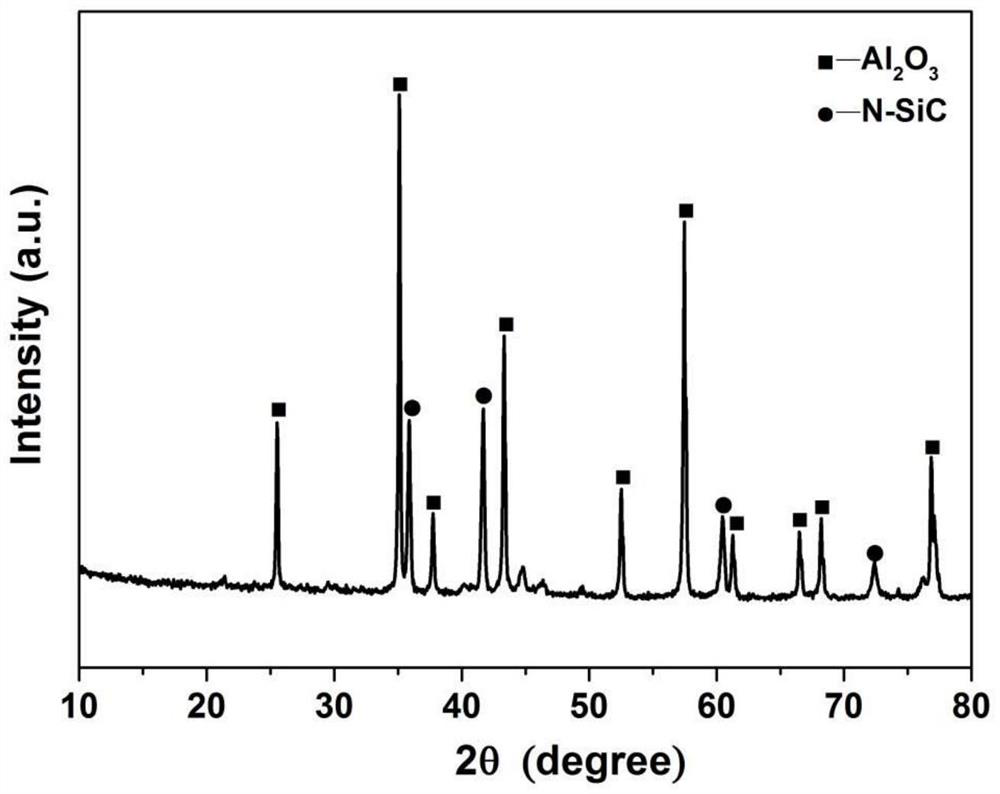

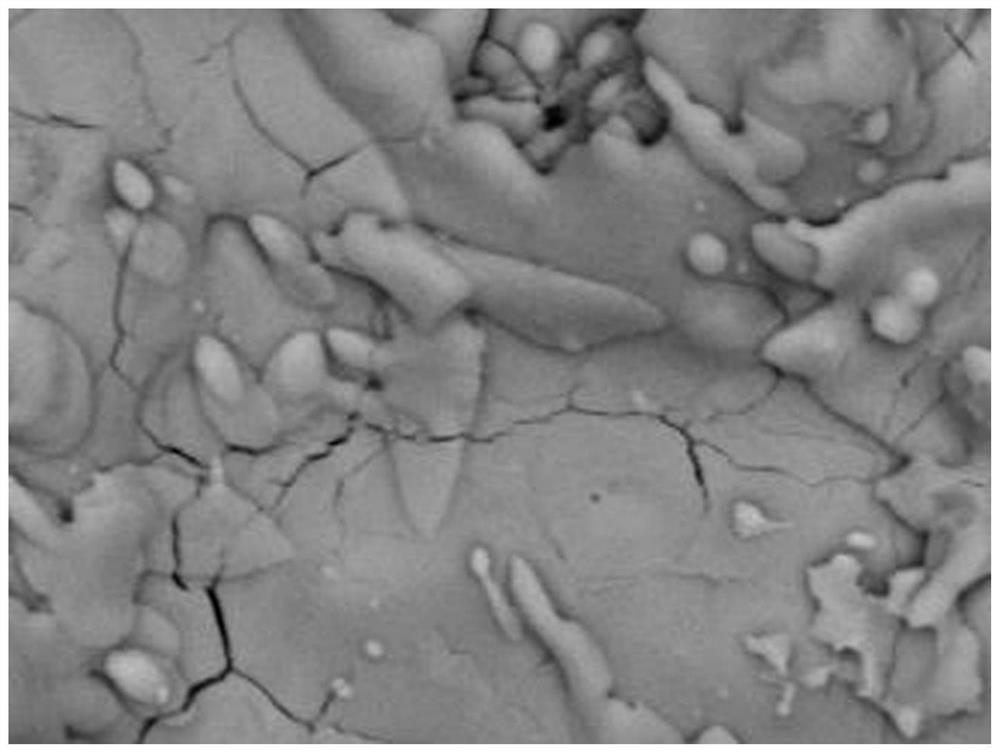

N-SiC/Al2O3 nano-composite anti-corrosion coating and preparation method thereof

A nano-composite and anti-corrosion technology, applied in coating, nanotechnology, metal material coating process, etc., can solve the problems of uneven distribution of components, coarse particle size, incomplete melting of coating, etc., and achieve low cost and high density High, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1, configure Al(NO 3 ) 3 9H 2 Aqueous solution of O; Al(NO 3 ) 3 9H 2 The volume of O solution is 1000mL, Al(NO 3 ) 3 9H 2 The mass fraction of O is 20wt.%;

[0045] Step 2, adding urea in a set ratio to the aqueous solution in step 1, the concentration of the urea solution is 1wt.%, and fully stirring to dissolve it;

[0046] Step 3, adding excess ammonia water dropwise to the mixed solution in step 2 and continuously stirring until a white precipitate is formed, the concentration of ammonia water is 30%;

[0047] Step 4, dissolving a certain amount of polycarbosilane (PCS) in xylene solution, the volume of the configuration solution is 300mL, and the mass fraction of polycarbosilane (PCS) is 20wt.%;

[0048] Step 5, adding the solution configured in step 4 and a certain amount of PVA aqueous solution to the solution in step 3, the concentration of the PVA aqueous solution is 3%, and its addition is 200mL;

[0049] Step 6, the mixture in step 5 is placed...

Embodiment 2

[0053] Step 1, configure Al(NO 3 ) 3 9H 2 Aqueous solution of O; Al(NO 3 ) 3 9H 2 The volume of O solution is 1000mL, Al(NO 3 ) 3 9H 2 The mass fraction of O is 50wt.%;

[0054] Step 2, adding urea in a set ratio to the aqueous solution in step 1, the concentration of the urea solution is 3wt.%, and fully stirring to dissolve it;

[0055] Step 3, adding excess ammonia water dropwise to the mixed solution in step 2 and continuously stirring until a white precipitate is formed, the concentration of ammonia water is 50%;

[0056] Step 4, dissolving a certain amount of polycarbosilane (PCS) in xylene solution, the volume of the configuration solution is 500mL, and the mass fraction of polycarbosilane (PCS) is 40wt.%;

[0057] Step 5, adding the solution configured in step 4 and a certain amount of PVA aqueous solution to the solution in step 3, the concentration of the PVA aqueous solution is 8%, and its addition is 300mL;

[0058] Step 6, the mixture in step 5 is placed...

Embodiment 3

[0062] Step 1, configure Al(NO 3 ) 3 9H 2 Aqueous solution of O; Al(NO 3 ) 3 9H 2 The volume of O solution is 1000mL, Al(NO 3 ) 3 9H 2 The mass fraction of O is 30wt.%;

[0063] Step 2, add urea in a set ratio to the aqueous solution in step 1, the concentration of the urea solution is 1.5wt.%, and dissolve it after fully stirring;

[0064] Step 3, adding excess ammonia water dropwise to the mixed solution in step 2 and continuously stirring until a white precipitate is formed, the concentration of ammonia water is 35%;

[0065] Step 4, dissolving a certain amount of polycarbosilane (PCS) in xylene solution, the volume of the configuration solution is 350mL, and the mass fraction of polycarbosilane (PCS) is 25wt.%;

[0066] Step 5, adding the solution configured in step 4 and a certain amount of PVA aqueous solution to the solution in step 3, the concentration of the PVA aqueous solution is 4.5%, and the addition amount is 230mL;

[0067] Step 6, placing the mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com